Vertical type tire dismounting device

A tire disassembly and vertical technology, which is applied in tire installation, tire parts, transportation and packaging, etc., can solve the problems of inability to adjust the working position of the pry board, the slipping of the rear end of the connecting rod, and the inability to adjust the working position, etc. , to achieve the effect of saving working time, reasonable and stable structure, and novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

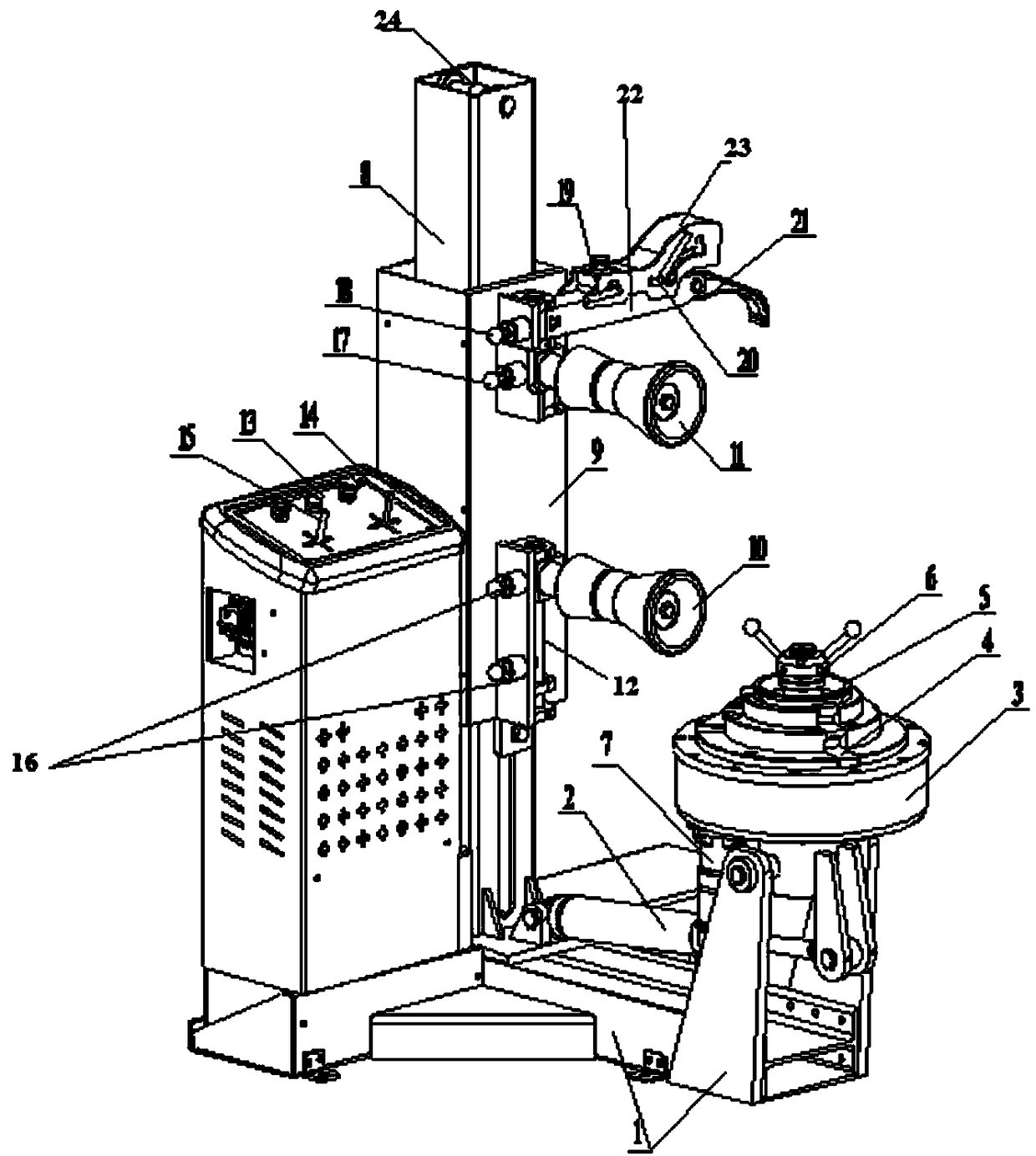

[0042] Such as Figure 1-Figure 5 As shown, the main structure of the vertical tire changing device of the present invention includes three parts: a base 1 , a column 8 and a console 13 .

[0043] When using this device to remove tires, it is necessary to stabilize the base 1, the column 8 and the console 13 at the same plane position, and the console 13 is the electrical and hydraulic power control assembly of the whole device.

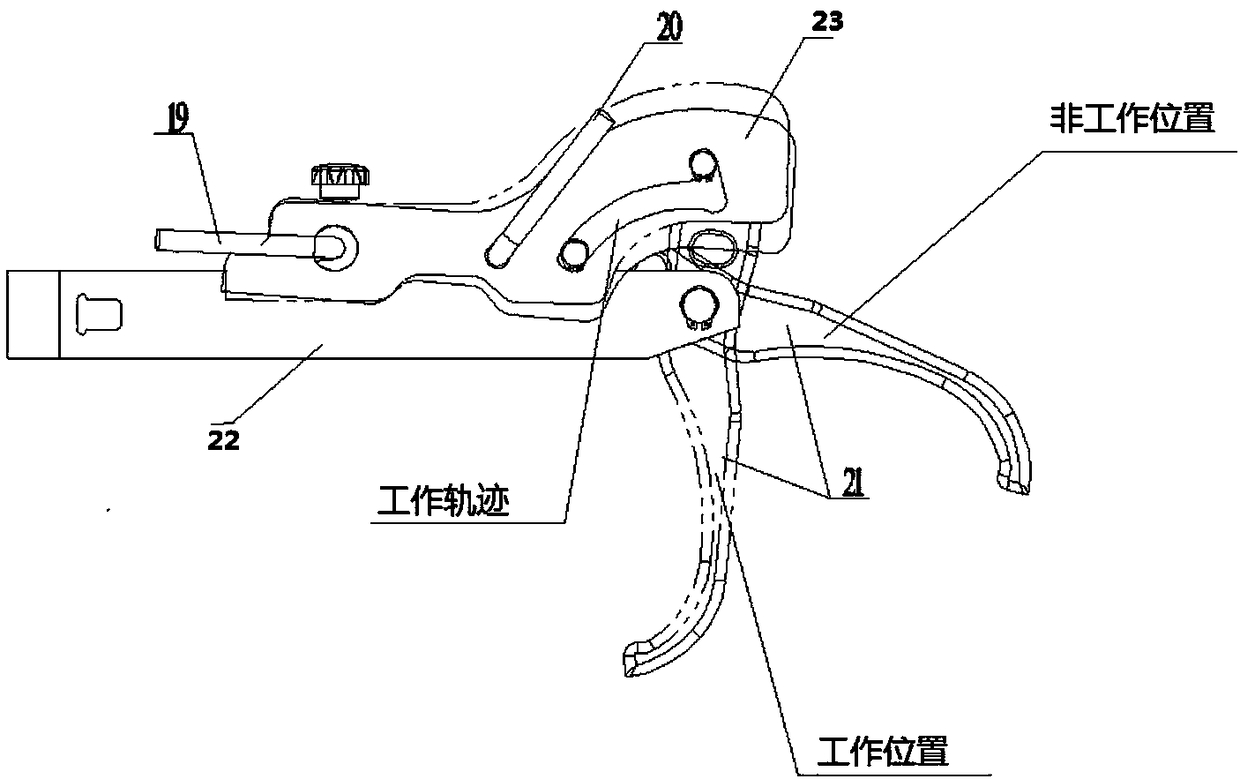

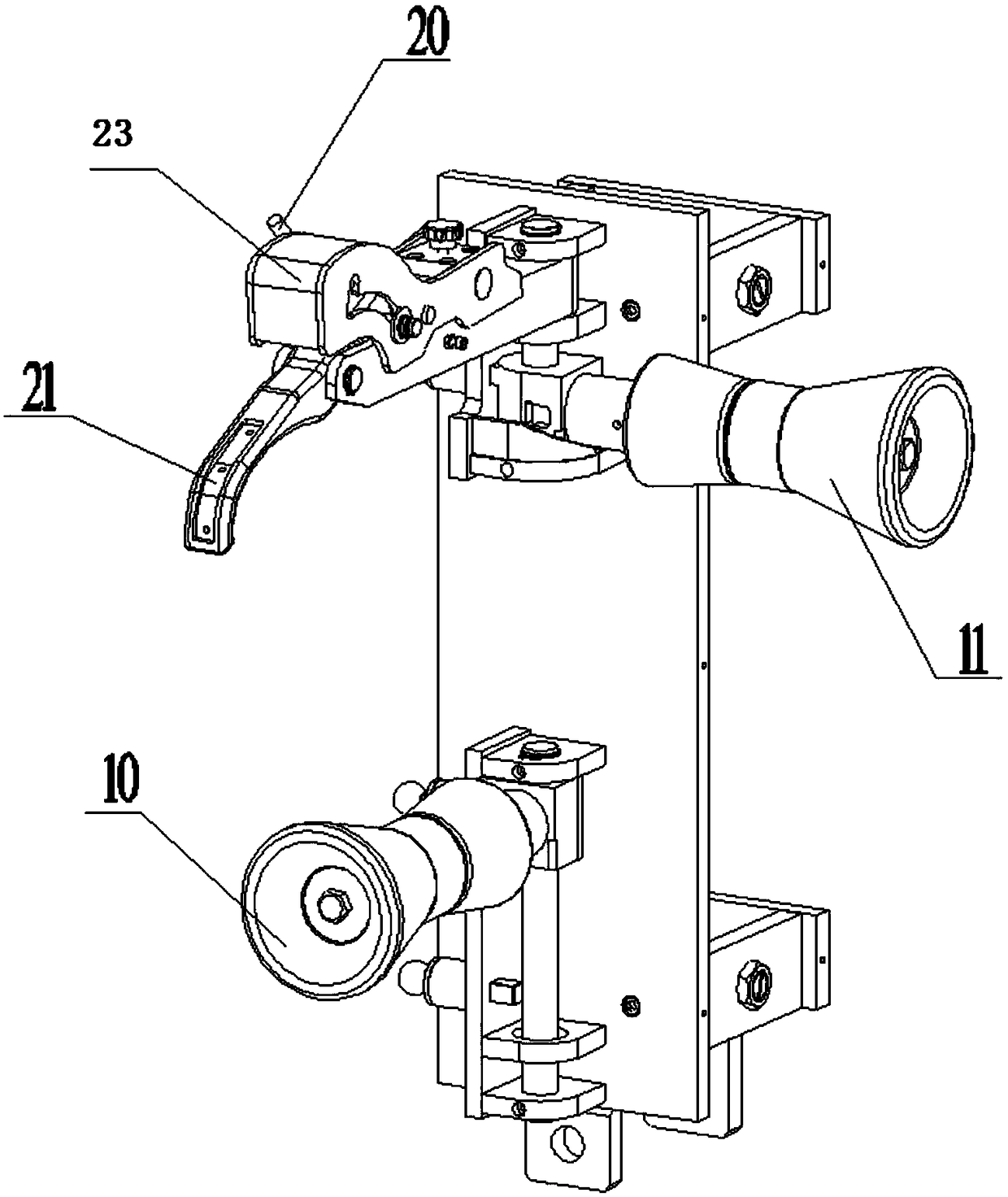

[0044] The tire removal hook assembly, the lower dismounting tire pressure roller 10 and the upper dismounting tire pressure roller 11 are in the non-working position when not in use, and the non-working position is perpendicular to the plane formed by the column and the round platform, that is, the parts are opposite to each other. Swing 90° horizontally to the left in the longitudinal direction of the column. When the tire removal hook assembly, the lower dismounting tire pressure roller 10 and the upper dismounting tire pressure roller 11 are in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com