LED constant-current drive circuit controlled through LLC resonance

A technology of constant current drive and resonance control, which is applied in the direction of electrical components, can solve the problems of increasing costs, and achieve the effects of improving response speed, shortening start-up delay time, and reducing circuit costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to deepen the understanding and recognition of the present invention, the present invention will be further described and introduced below in conjunction with the accompanying drawings.

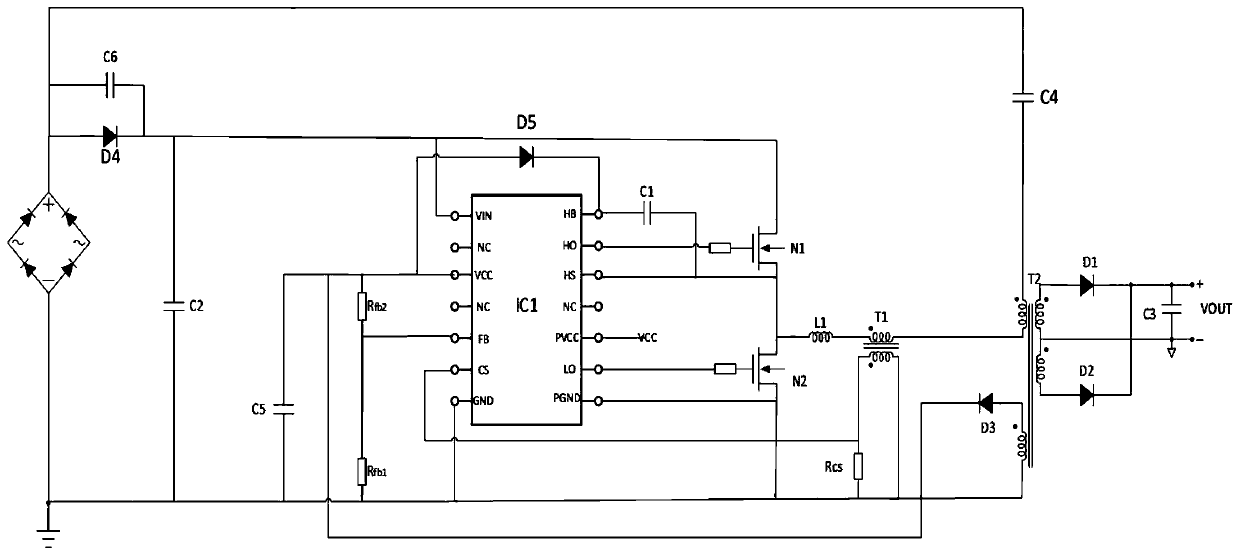

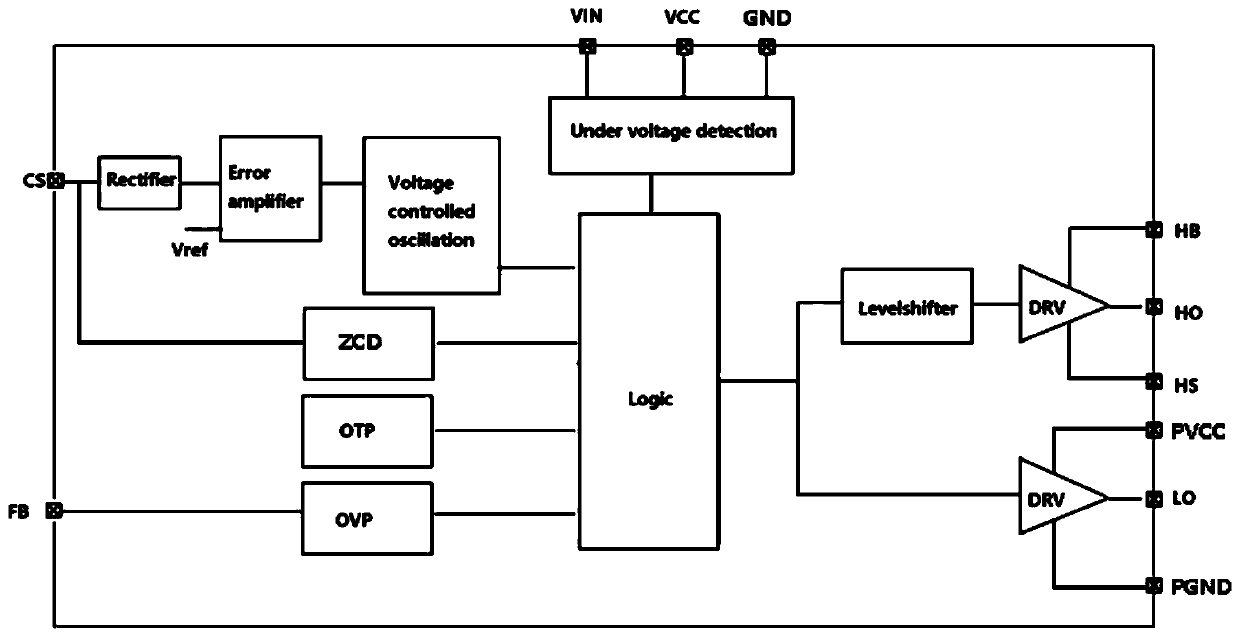

[0022] Such as figure 1 As shown, it is a LED constant current drive circuit controlled by LLC resonance shown in a preferred embodiment of the present invention, including a rectifier circuit, a half-bridge drive chip IC1, a first power transistor N1, a second power transistor N2, and a resonant inductor L1, resonant capacitor C4, first transformer T1, second transformer T2, first to fifth diodes, first to third capacitors, fifth to sixth capacitors, first resistor Rcs, second resistor Rfb2 and the first Three resistors Rfb1, the rectification circuit is realized by a full-bridge rectification circuit composed of four diodes, the positive output terminal of the rectification circuit is connected to the VIN pin of the half-bridge driver chip IC1 through the fourth diode D4, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com