Method for visualizing fault state monitoring

A fault state and normal state technology, applied in the field of monitoring visualization, can solve the problems of inability to guarantee the effectiveness of monitoring, changes in observation parameters, and inability to achieve the effect of solving visualization problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0029] The visualization method of fault state monitoring of the present invention:

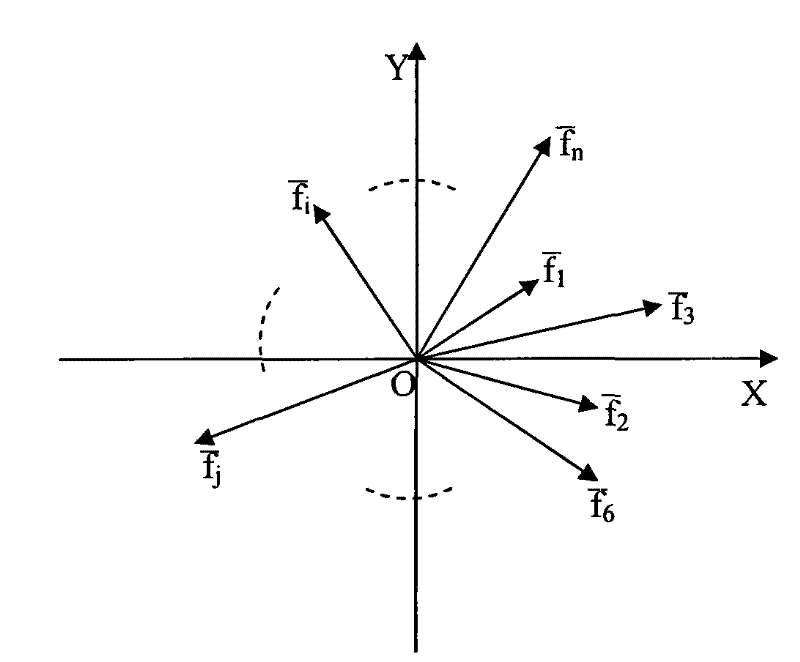

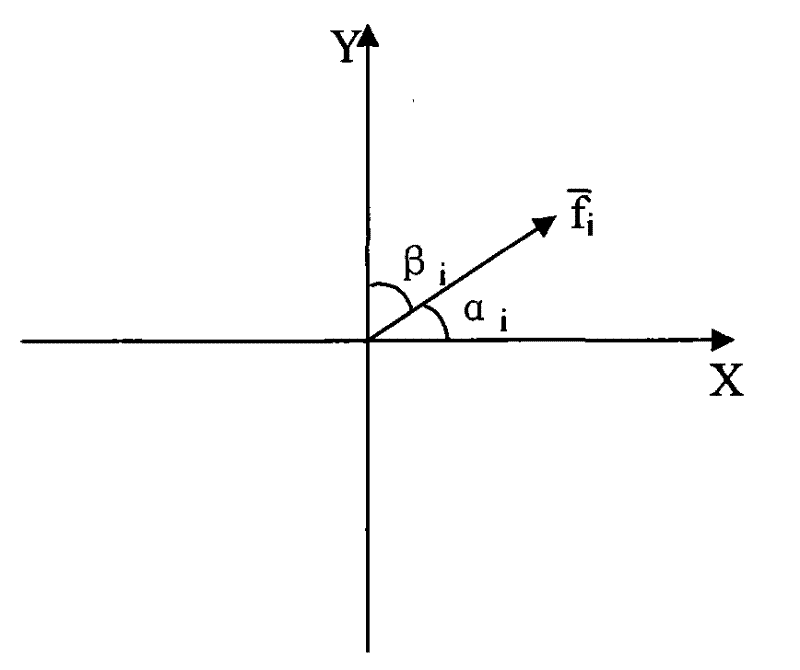

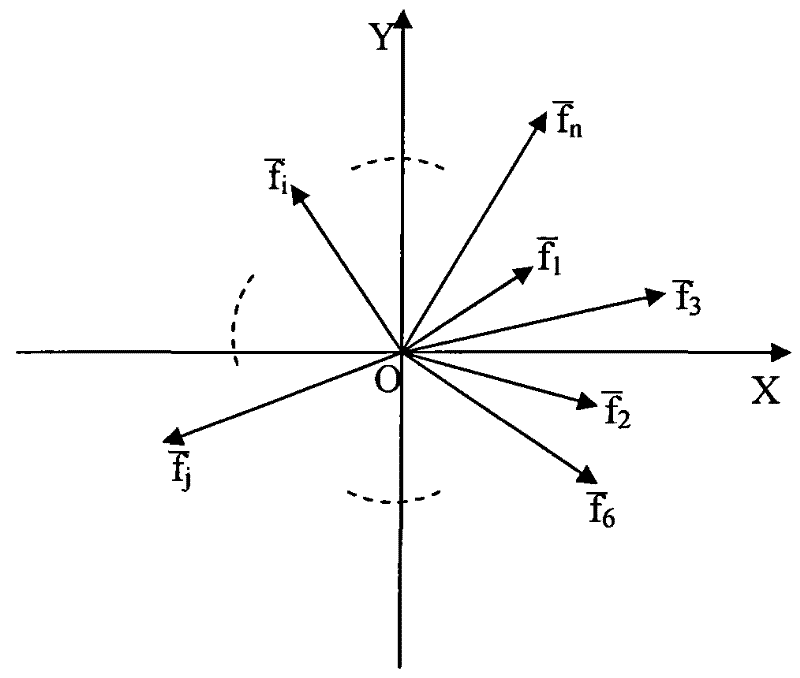

[0030] Let the fault characteristic parameter be F={f 1 , f 2 ,..., f n}, the origin of the XY plane coordinate system is (0, 0), each fault characteristic parameter f i (i=1, 2, ..., n) use a vector f whose starting point is the origin i (i=1, 2,...,n) means that n fault characteristic parameter vector directions are evenly distributed on the XY plane, and its direction is fixed, and its length depends on the fault characteristic parameter f i (i=1, 2, ..., n) size, such as figure 1 shown.

[0031] When the number of fault characteristic parameters is n, the interval angle of each fault characteristic parameter vector is 360° / n, so that they are evenly distributed on the XY plane. The arrangement order of the fault characteristic parameter vector is related to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com