Grass trimmer

A lawn mower and mowing head technology, applied in the field of lawn mowers, can solve the problem of visualization, reduce root wear and avoid friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

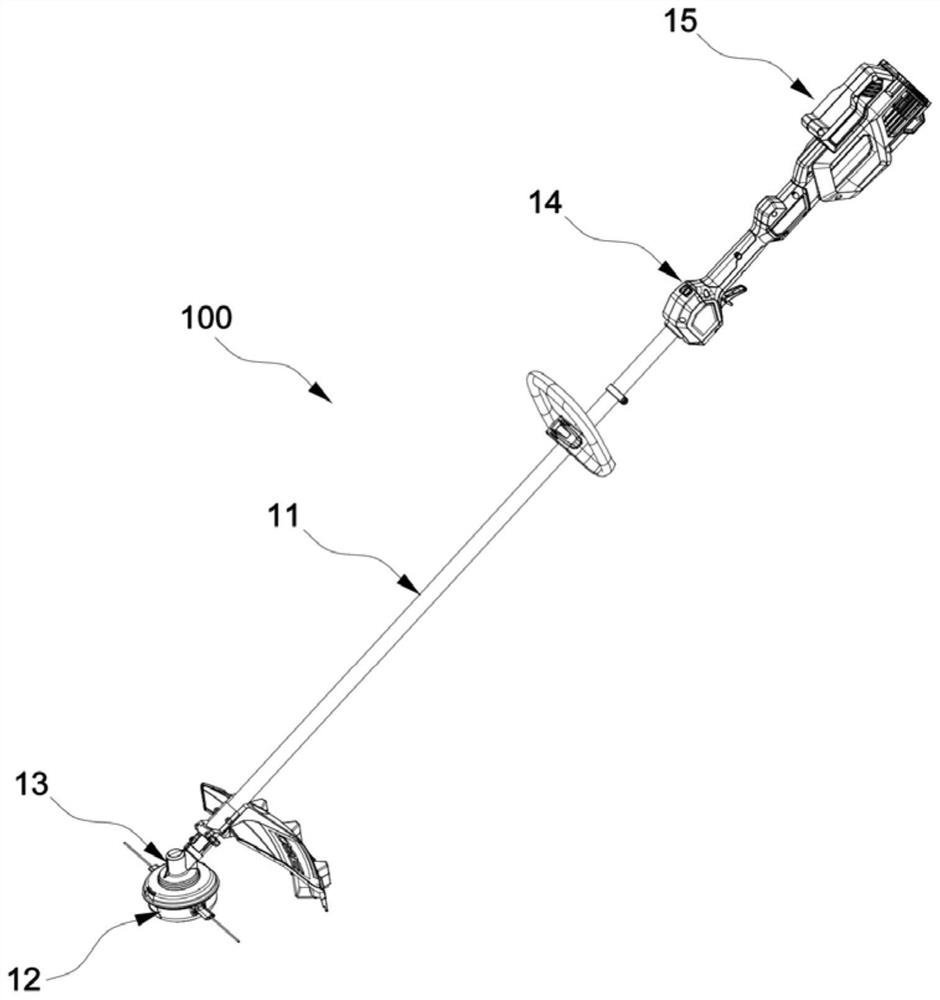

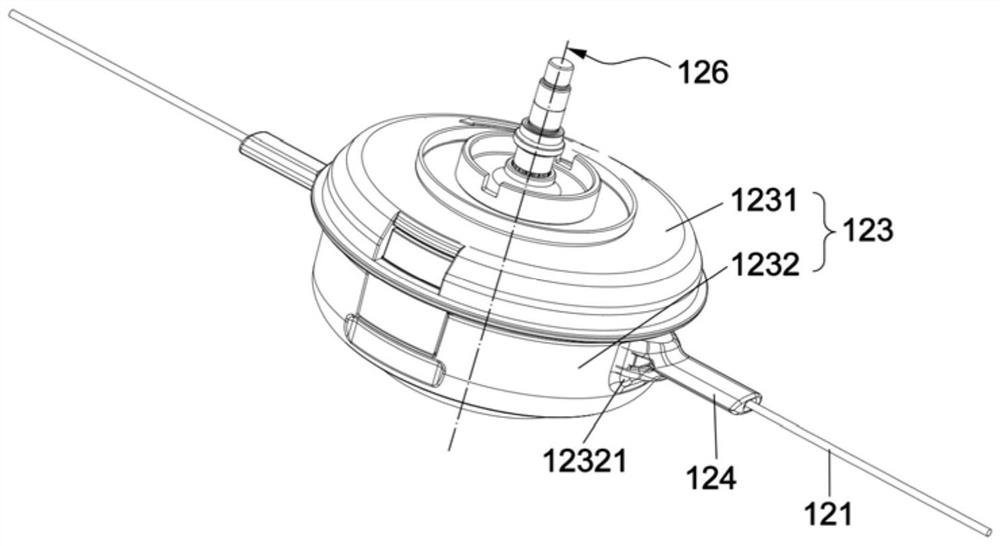

[0041] This embodiment discloses a grass trimmer 100, such as figure 1 and figure 2 As shown, the mowing machine 100 includes a connecting rod 11 , a mowing head 12 , a driving part 13 , an operating part 14 and a coupling part 15 . Wherein, one end of the connecting rod 11 is connected to the driving part 13 , and the other end is connected to the operating part 14 . The coupling portion 15 is disposed at an end of the operating portion 14 away from the connecting rod 11 . The mowing head 12 is connected to the driving part 13 and can mow grass when being driven; The operation part 14 is operable by a user to control the mower 100 . As an implementation method, the mowing machine 100 can not only reduce the risk of the mowing rope 121 breaking from the root, reduce maintenance and replacement costs, prolong the service life of the mowing machine 100, but also realize the visualization of the mowing rope 121, and effectively Weaken the aerodynamic noise when the grass rop...

Embodiment 2

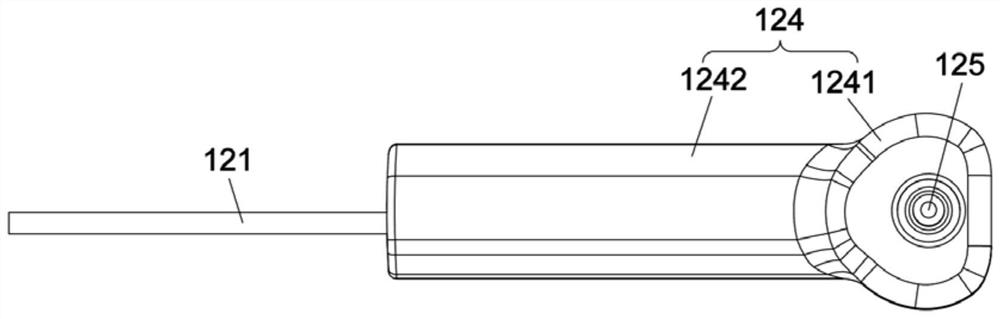

[0055] This embodiment provides a lawn trimmer 100, which is basically the same as the lawn trimmer 100 in Embodiment 1, the only difference being that the structure of the protective structure 124 of the grass trimmer 100 in this embodiment is different.

[0056] Specifically, the protective structure 124 in this embodiment is a split structure, which includes a first body and a second body, one side of the first body is rotatably connected to one side of the second body, and the other side of the first body One side and the other side of the second body are opened or locked by a locking mechanism (not shown in the figure).

[0057] During actual assembly, the locking mechanism is unlocked, the first body and the second body are opened, the mowing rope 121 is put into the through channel, and then the first body and the second body are fastened together, and the protective structure 124 is locked by the locking structure. locking, so as to realize the fixing of the mowing rop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com