Dust collection mechanism on air duct cleaning robot and air duct cleaning robot

A technology for cleaning robots and dust collection mechanisms, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., and can solve problems such as poor control effects, affecting work efficiency, and affecting dust collection effects, so as to ensure suction Dust effect, easy installation and maintenance, good maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

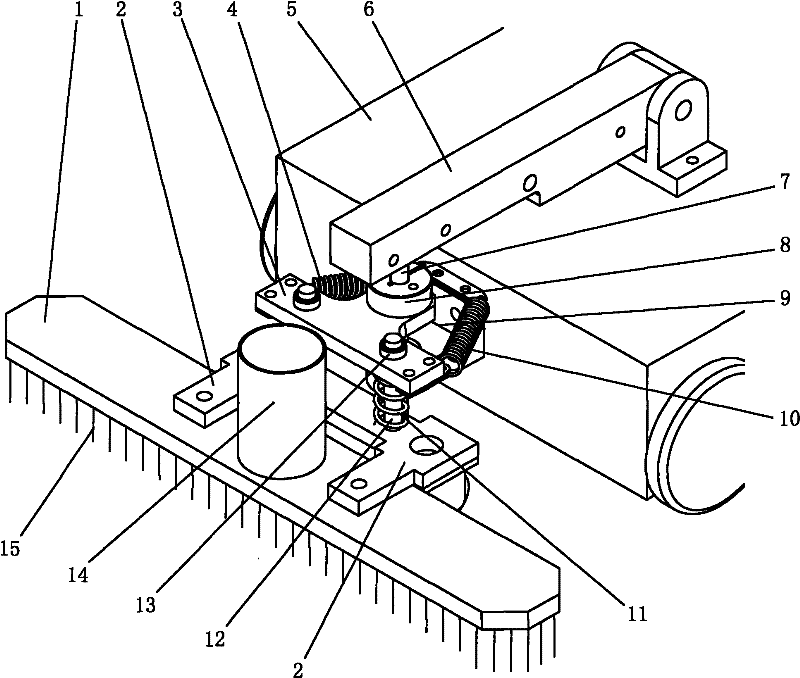

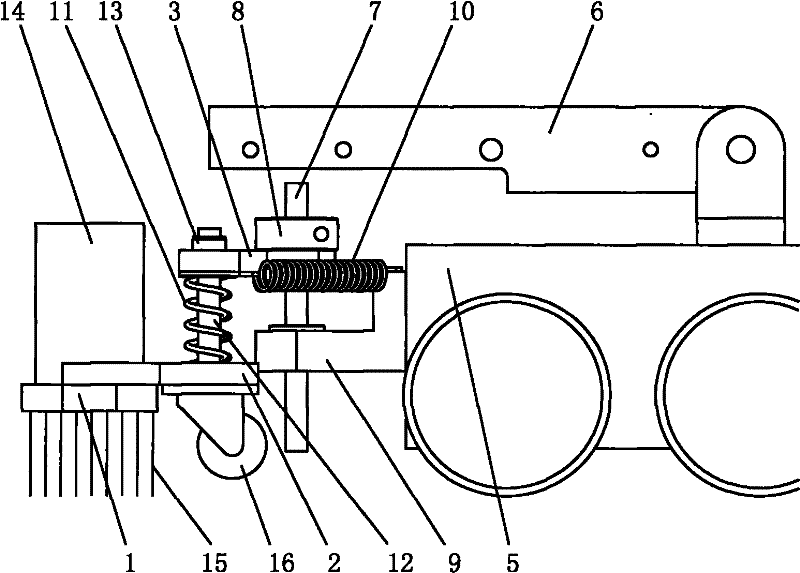

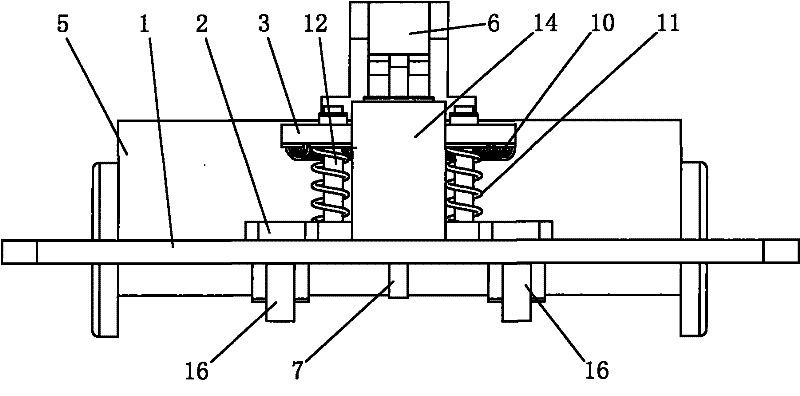

[0021] like Figure 1 to Figure 4 The dust suction mechanism on the air duct cleaning robot shown includes a dust suction port 1 and a trolley body 5, the trolley body 5 is hinged with a rocker arm 6, and the rocker arm 6 is lifted and positioned under the control of a driving mechanism; The front of the trolley body 5 is fixed with a connecting seat 9, and the connecting seat 9 is connected with a long guide rod 7. The lower end of the long guide rod 7 passes through the connecting seat 9 and can rotate and vertically move up and down relative to the connecting seat 9. The upper end of the guide rod 7 is covered with a floating plate 3, the floating plate 3 is fixedly connected with the long guide rod 7 through the fixed ring 8, and the left and right sides of the floating plate 3 are respectively connected to the connecting seat 9 or the trolley through the extension springs 4, 10. The car body 5 is connected (due to the effect of the tension spring, the floating plate is al...

Embodiment 2

[0026] An air duct cleaning robot, comprising a trolley body, the front of the trolley body is provided with a dust suction mechanism as described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com