Laser generating device of laser marking machine

A laser marking machine and laser generation technology, applied in the direction of laser cooling devices, lasers, phonon exciters, etc., can solve problems such as condensation of laser modules, achieve the effects of increasing service life, ingenious ideas, and highlighting substantive features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

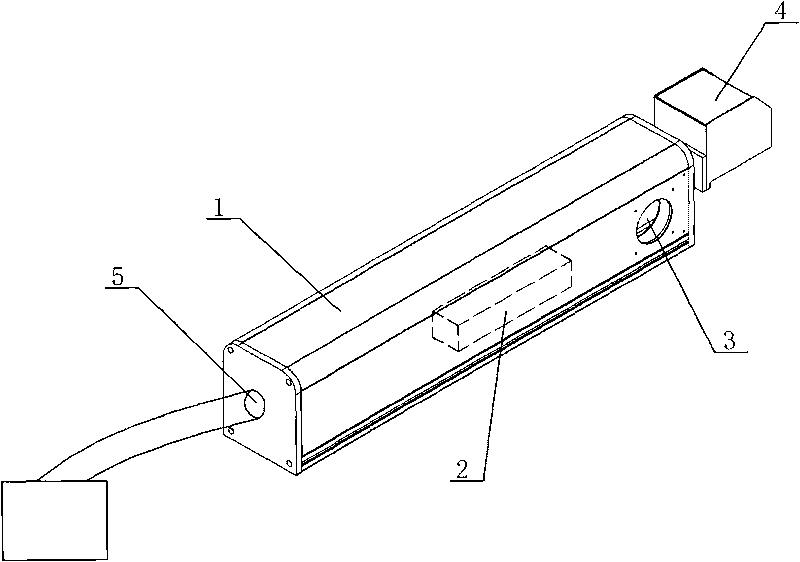

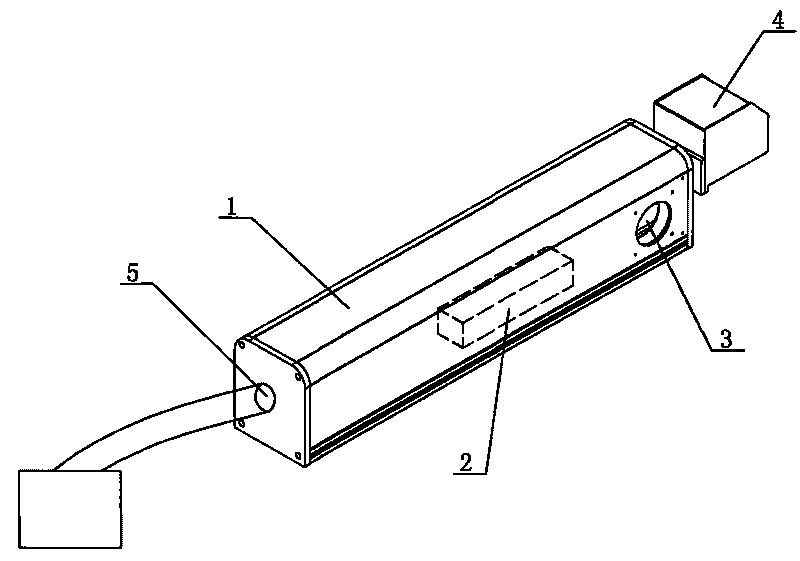

[0009] As shown in the accompanying drawings, the laser generating device of the laser marking machine has a casing 1, and one side of the casing 1 is provided with a vibrating lens 4 (the function of the vibrating lens is to adjust the direction of the laser emitted by the laser module). The casing 1 is a closed shell with an air inlet 5 and an air outlet 3, the air inlet 5 communicates with the air conditioning cooling system, the air inlet 5 is located on the side of the casing 1 away from the vibrating head 4, and the air outlet 3 It is arranged on the side of the casing 1 close to the vibrating head 4, and the laser module 2 is arranged in the casing 1 (the cooling of the laser module adopts water cooling).

[0010] When the laser marking machine is working, the laser module is in the working environment with the air supply of the air conditioning cooling system, and its exhaust is discharged through the air outlet. The ambient temperature is stable and the humidity is low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com