Jewelry chain and manufacturing method thereof

A production method and technology for jewelry chains, which can be applied to decorative chains, clothing, watch chains, etc., can solve the problems of large loss of jewelry chains, small size of jewelry chains, and not enough soft and beautiful shapes, and achieve the advantages of small loss, large volume, and dense structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

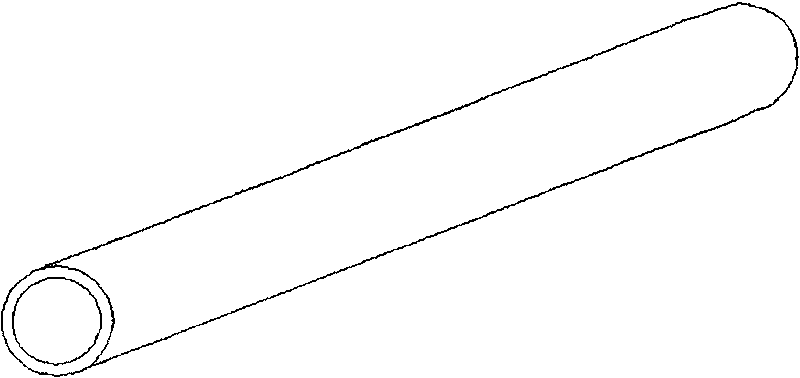

[0024] Such as figure 1 As shown, the gold is pressed into a thin sheet with a thickness of 0.3mm, one end of which is rolled into a circle, passed through a wire drawing die with a diameter of 2.0mm, and can be drawn into a hollow round wire with a diameter of 2.0mm; depending on the diameter of the wire drawing die, Different models, that is, hollow round wires with different diameters, can be drawn.

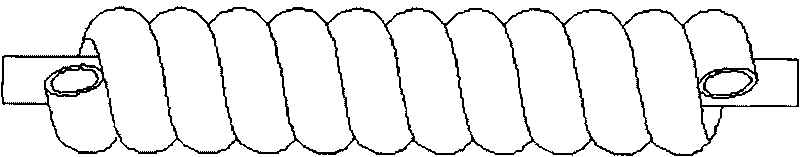

[0025] Such as figure 2 As shown, the drawn hollow round wire is wound on the smooth winding mandrel, and the speed is kept uniform during winding.

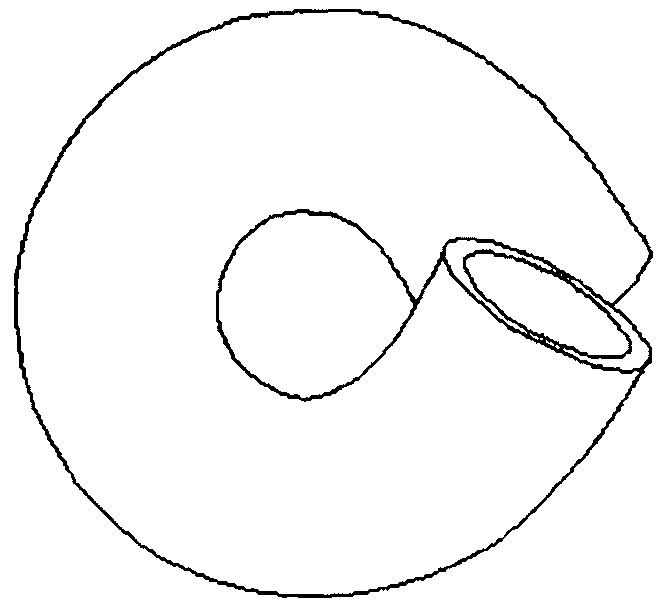

[0026] Such as image 3 As shown, after winding, cut the hollow round wire along the direction of the winding mandrel to make an open hollow link of the same size and shape.

[0027] Such as Figure 4-5 As shown, in order to heat up the cooled and hardened gold and make it easier to carry out the next step, therefore, te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com