Motorcycle secondary gulp valve bracket mounting structure

A secondary air supply and installation structure technology, applied in the direction of power devices, vehicle parts, bicycle accessories, etc., can solve the problems of easy deformation and aliasing, failure of secondary air supply valve, easy wear of hoses, etc., to achieve Guaranteed performance, guaranteed service life, and the effect of preventing deformation and aliasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

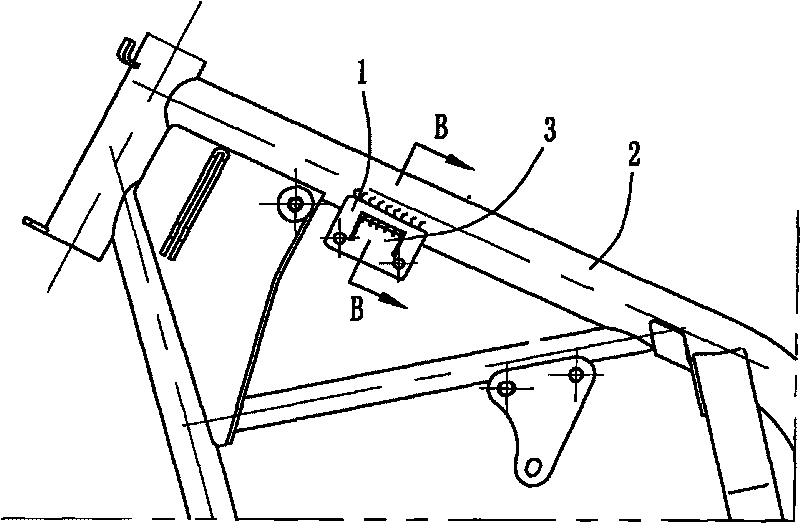

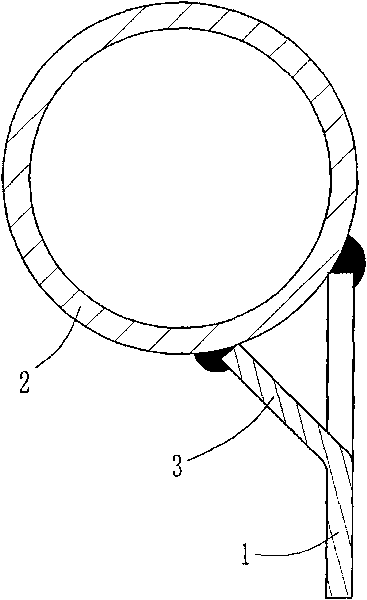

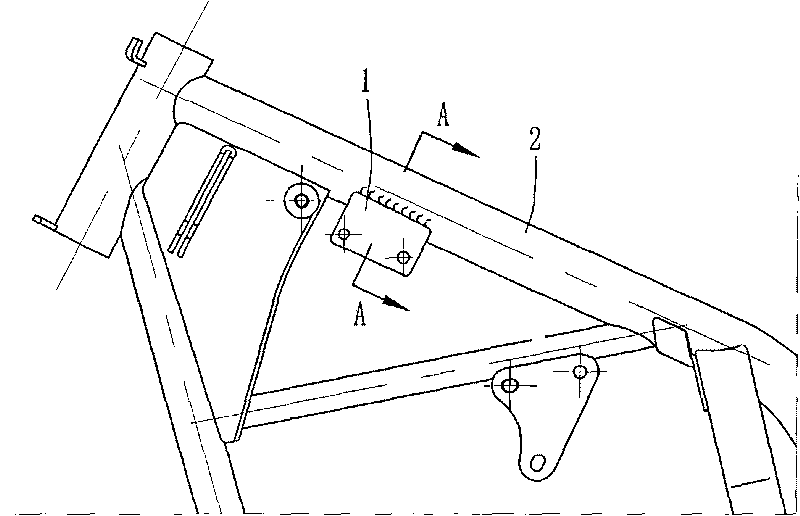

[0014] Such as figure 1 , figure 2 As shown, the present invention is made of support 1 and front main pipe 2 of vehicle frame, and front main pipe 2 of vehicle frame adopts prior art, and its structure and arrangement form are not repeated here. The bracket 1 is a rectangular flat plate structure, the long side direction of the bracket 1 is in the same direction as the axis of the front main pipe 2 of the vehicle frame, and one of the long sides of the bracket 1 is welded with the front main tube 2 of the vehicle frame, and the other side near the bracket 1 There are through holes at both ends of the board surface of the long side, so that the secondary air supply valve can be installed on the bracket 1 through bolts. A building block 3 is formed on the bracket 1 by stamping, the building block 3 is rectangular, and the long side of the building block 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com