Special vehicle body with double bearing structures

A technology of load-bearing structure and special vehicle, applied in the direction of load-bearing body structure, substructure, superstructure, etc., can solve the problems of inconvenient maintenance and small space inside the buoyancy cabin, and achieve the effect of reducing the number of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

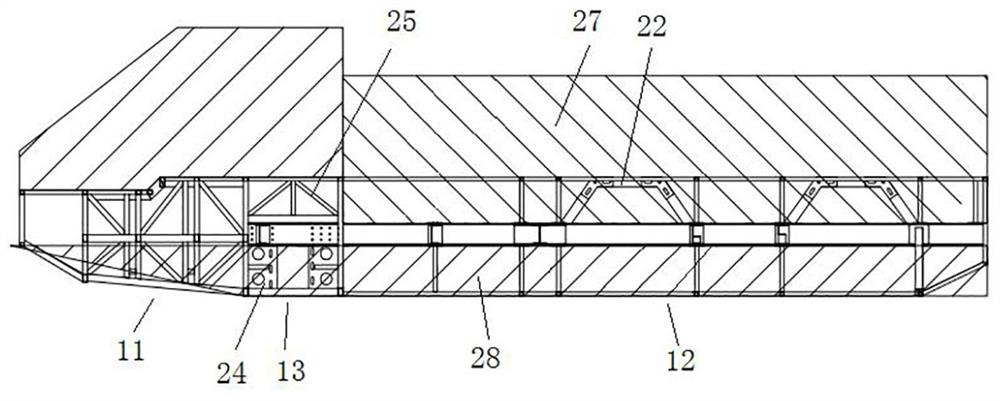

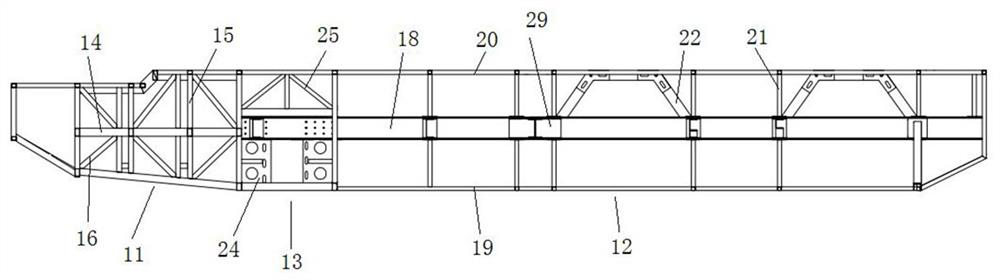

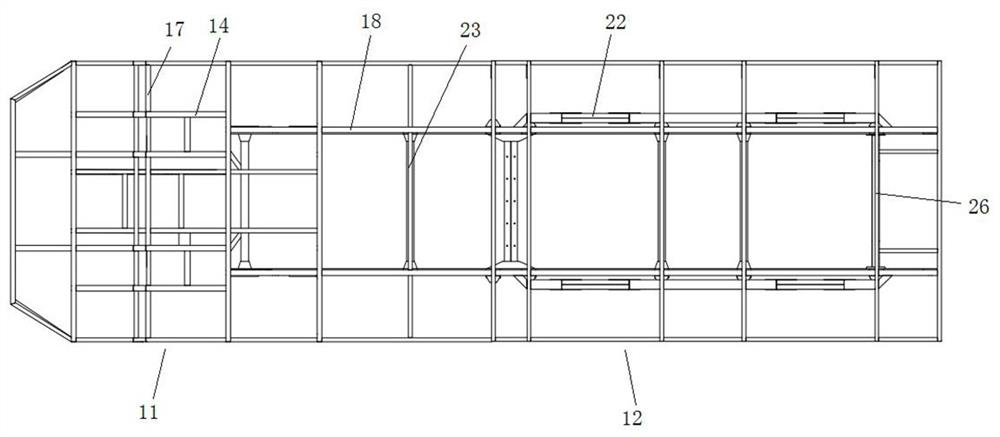

[0039] In this example, if figure 1 As shown, the body of a special vehicle with a double load-carrying structure includes a frame and a shell. structure, but also has a hull structure. The vehicle frame includes a driver's cab bearing part 11 and an upper loading bearing part 12. The driver's cab bearing part 11 is equipped with two steering wheels, and the vehicle frame behind the steering wheels is the upper loading bearing part 12. The front part of the cab carrying part 11 is provided with an imitation bow part, and the imitation bow part forms a slope to facilitate the installation of the opposite skin, so that the front part of the frame forms a bow structure, which is better for breaking waves and more effective. It is beneficial to ensure the speed of driving.

[0040] In this example, if figure 1 and figure 2 As shown, the cab bearing part 11 includes a cab longitudinal beam 14, a cab beam 17 and a cab column 15, the cab beam 17 is provided with three layers, th...

Embodiment 2

[0050] The difference between this embodiment and Embodiment 1 is that: the end face of the load-carrying main girder is provided with an angle connector for fixed connection with the transition connection truss.

Embodiment 3

[0052] The difference between this embodiment and Embodiment 1 is that in this embodiment, the reinforced plate is replaced by a profile.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com