Battery pack used for being horizontally hung on electric automobile and electric automobile

A technology for electric vehicles and battery packs, applied in electric vehicle charging technology, electric vehicles, secondary batteries, etc., can solve problems such as sinking, deformation of battery packs, poor seismic performance, etc. The effect of improving installation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

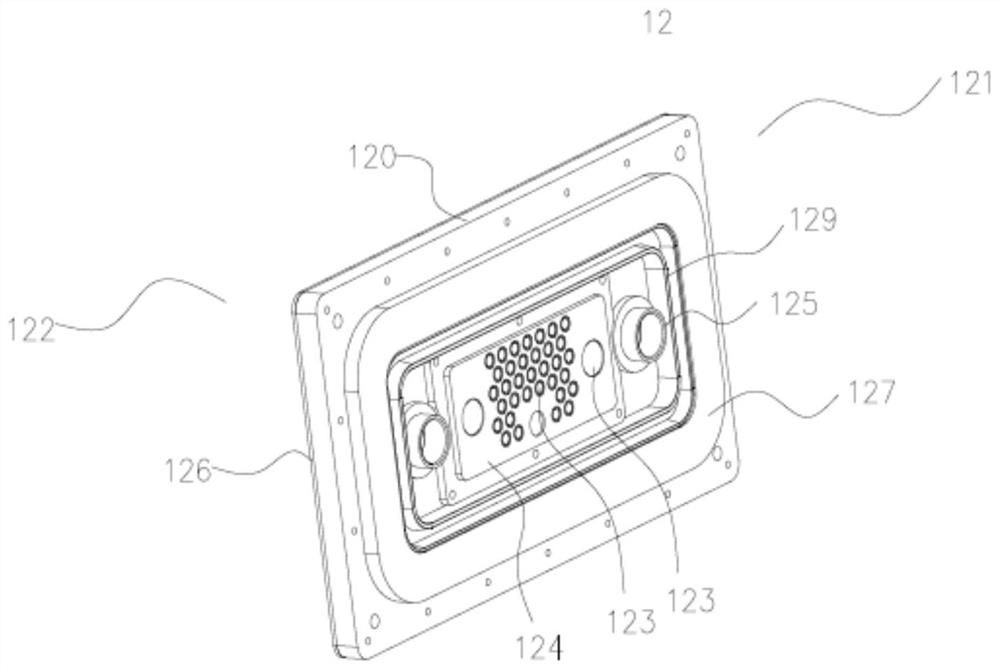

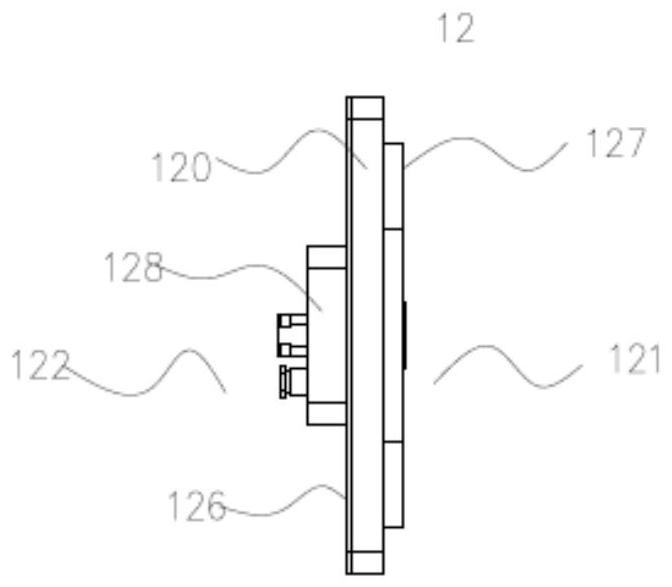

[0089] This embodiment provides a battery terminal electrical connector for battery replacement.

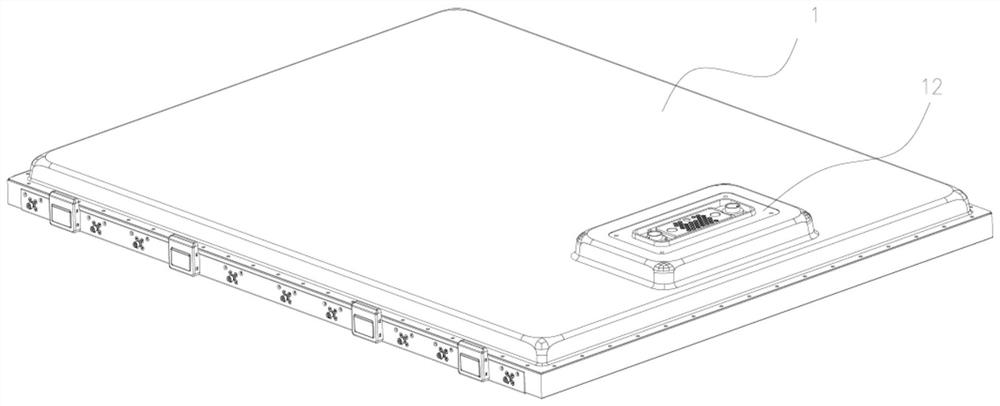

[0090] Such as figure 2 and image 3 As shown, the battery terminal electrical connector 12 includes a mounting side 121 and a conductive output side 122 . Such as figure 1 and Figure 4 As shown, the battery terminal electrical connector 12 is installed on the battery pack 1 through the installation side 121, and the battery pack 1 is used to be installed on an electric vehicle to provide power for the electric vehicle (not shown). Conductive output side 122 . The conductive output side 122 is arranged on the top of the battery pack 1 , and is arranged to be connected to the vehicle end electrical connector 22 of the electric vehicle in a bottom-up direction.

[0091] In this embodiment, the installation side 121 and the conductive output side 122 are non-perpendicularly arranged. In order to facilitate installation, usually the top of the battery pack has a horizontal pla...

Embodiment 2

[0105] This embodiment provides another battery terminal electrical connector for battery replacement.

[0106] Such as Figure 8 and Figure 9 As shown, the battery terminal electrical connector 12 includes a mounting side 121 and a conductive output side 122 . Such as Figure 7 and Figure 10 As shown, the battery terminal electrical connector 12 is installed on the battery pack 1 through the installation side 121, and the battery pack 1 is used to be installed on an electric vehicle (not shown in the figure) to provide power for the electric vehicle. The conductive output side 122 is arranged on the top of the battery pack 1 and is arranged to be connected with the electrical connector 22 of the electric vehicle in a horizontal direction.

[0107] In this embodiment, based on the fact that the top of the battery pack 1 has a bump 13, the bump 13 has a mounting surface perpendicular to the horizontal projection plane of the top surface of the battery pack 1, so the mount...

Embodiment 3

[0116] This embodiment provides a vehicle end electrical connector.

[0117] Such as Figure 11-Figure 13 As shown, the vehicle end electrical connector 22 includes a fixed side 221 and a conductive input side 222 . The vehicle-end electrical connector 22 is installed into the battery accommodation chamber of the electric vehicle through the fixed side 221 , and the battery accommodation chamber is formed upwardly from the bottom of the electric vehicle. The conductive input side 222 is disposed on the top of the battery receiving cavity, and is configured to be connected to the battery terminal electrical connector 12 in a bottom-up direction.

[0118] In this embodiment, the fixed side 221 and the conductive input side 222 are arranged non-perpendicularly; or, the fixed side 221 and the conductive input side 222 are arranged in parallel. Specifically, the positional relationship between the fixed side 221 and the conductive input side 222 is preferably that when the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com