High-current inductor

An inductor, high-current technology, applied in the direction of transformer/inductor coil/winding/connection, clamping/spring connection, etc., can solve the problems of poor circuit space utilization, easy loosening and falling off, long wire pins, etc. Easy to connect and install, not easy to loosen and fall off, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

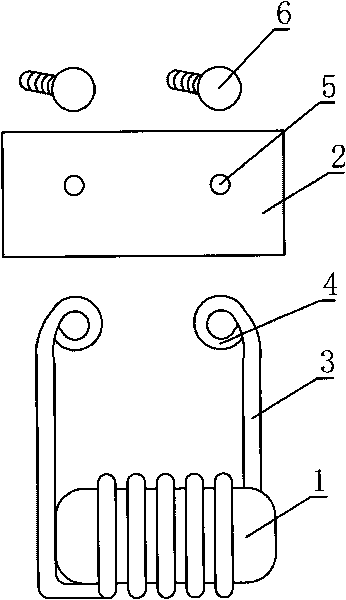

[0016] Such as figure 1 , a high-current inductor, including an inductor body 1, the inductor body 1 is provided with a pin 3 connected to a circuit board 2, and a connecting device is provided between the pin 3 and the circuit board 2. The connecting device includes a buckle 4 arranged at the end of the pin 3, a screw hole 5 corresponding to the buckle 4 on the circuit board 2 and a screw 6. Put the buckle 4 on the screw hole 5, and the screw 6 passes through The buckle 4 is connected with the screw hole 5 to fix the buckle 4. It is easy to install, has good firmness, and does not need welding, which improves the installation speed. The buckle 4 and the pin 3 are integrally structured. Directly by the pin 3 The ends are bent to save material.

Embodiment 2

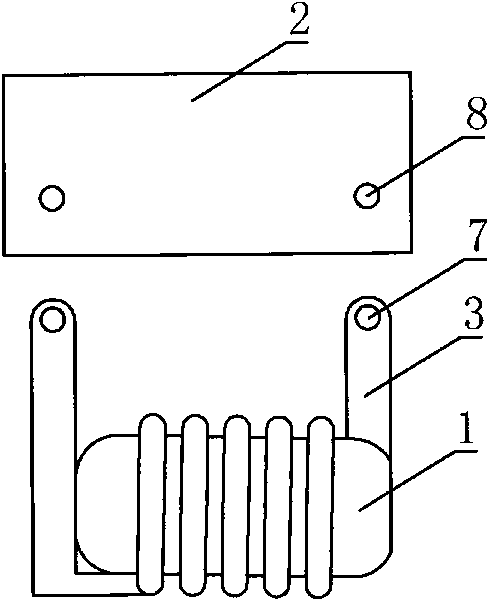

[0018] Such as figure 2 , a large current inductor, comprising an inductor body 1, the inductor body 1 is provided with a pin 3 connected to a circuit board 2, and a connection device is provided between the pin 3 and the circuit board 2. The connecting device includes a terminal 7 arranged at the end of the pin 3 , and a terminal hole 8 arranged on the circuit board 2 corresponding to the terminal 7 . The terminal 7 is directly fixed with the terminal hole 8, and the installation speed is fast. The terminal 7 is welded on the pin 3 by means of welding.

Embodiment 3

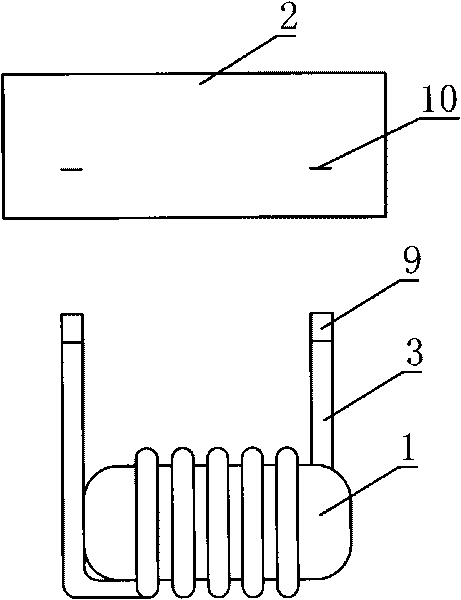

[0020] Such as image 3 , a large current inductor, comprising an inductor body 1, the inductor body 1 is provided with a pin 3 connected to a circuit board 2, and a connection device is provided between the pin 3 and the circuit board 2. The connecting device includes a plug-in piece 9 arranged at the end of the pin 3 , and a plug-in interface 10 corresponding to the plug-in piece 9 arranged on the circuit board 2 . Insert the plug piece 9 into the socket 10 for fixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com