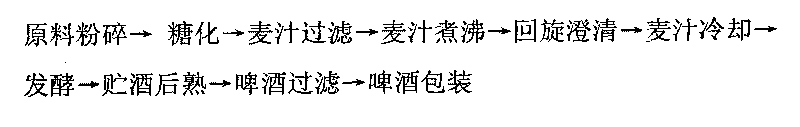

Deep beer storage technology and application thereof

A technology for storing wine and beer, which is applied in the technical field of wine storage stage of beer brewing, which can solve the problems of single function, not strong uniqueness of beer flavor, and inconspicuous improvement of beer flavor, etc., and achieve the effect of improving beer taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The wine storage stage of beer brewing includes the following sequential steps: (1) aging of wine after storage: 10-20 days of wine storage in traditional stainless steel or enamel wine storage tanks; (2) wine storage in oak barrels, wherein the temperature of wine storage is controlled at -1.5~1℃, storage time is at least one week, and sealed. The storage time is determined by the degree of oak taste.

[0015] Finally, through step (3) blending, the aroma and taste are consistent, so as to achieve the purpose of beer with unique smell, mellow taste, mellow and harmonious.

[0016] The production equipment needs to add oak barrels and wine storage rooms on the basis of the original equipment.

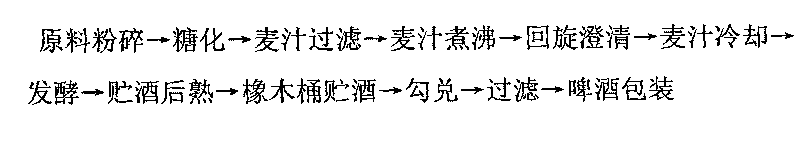

[0017] Application of the beer production technology of this embodiment see figure 2 ,in

[0018] Raw material crushing : The malt and other raw materials are respectively crushed by a pulverizer to a pulverization degree suitable for saccharification operation.

[0019] ...

Embodiment 2

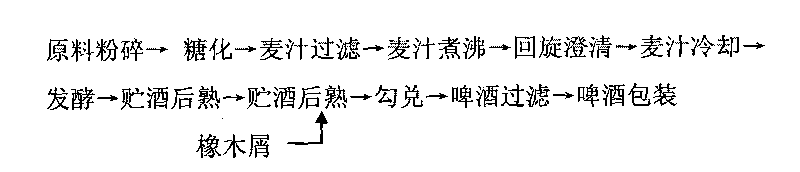

[0031] Application of the beer production technology of this embodiment see image 3 .

[0032] The production equipment can adopt the original equipment.

[0033] In this embodiment, on the basis of the original production process, different doses of oak chips are added in another traditional stainless steel or enamel wine storage tank. The amount of wood chips added is generally less than 1.5% (m / m). The wine storage temperature is controlled at -1.5-1°C, the storage time is at least one week, and the cans are sealed. The amount of wood chips added, storage time, etc. should be controlled and determined according to the degree of oak taste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com