Corrugated Cylindrical Magnetorheological Rubber Shock Absorber

A technology of magnetorheological shock absorber and magnetorheological rubber, which is applied in the direction of shock absorber, shock absorber-spring combination, shock absorber, etc., can solve the problems of limited damping force and work efficiency that needs to be further improved. To achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described now in conjunction with accompanying drawing.

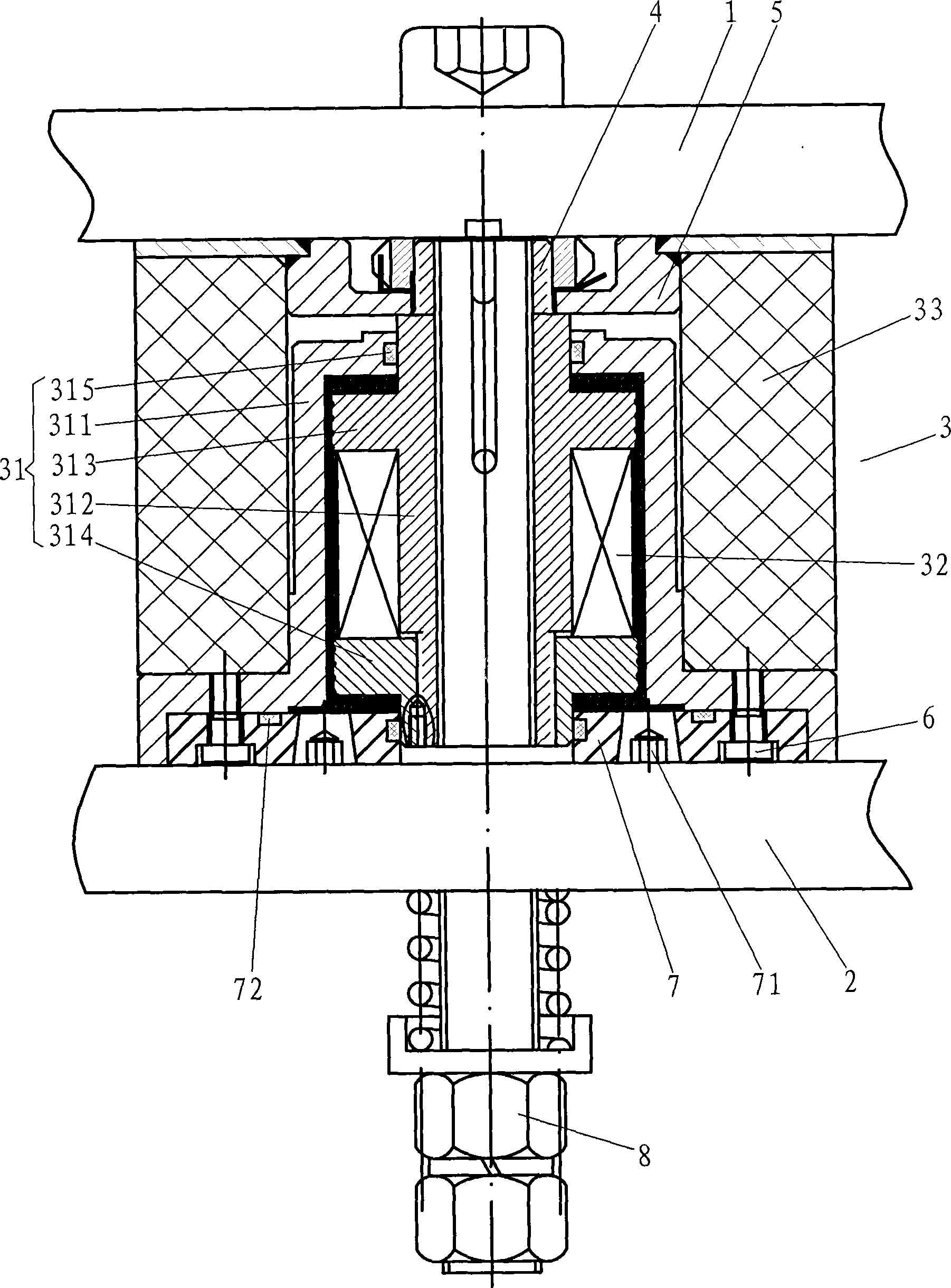

[0015] Corrugated cylinder magnetorheological rubber shock absorber of the present invention, as figure 1 , 2 As shown, it includes a vibrating table frame 1 , a supporting base 2 and a magneto-rheological damper 3 installed between the vibrating table frame 1 and the supporting base 2 .

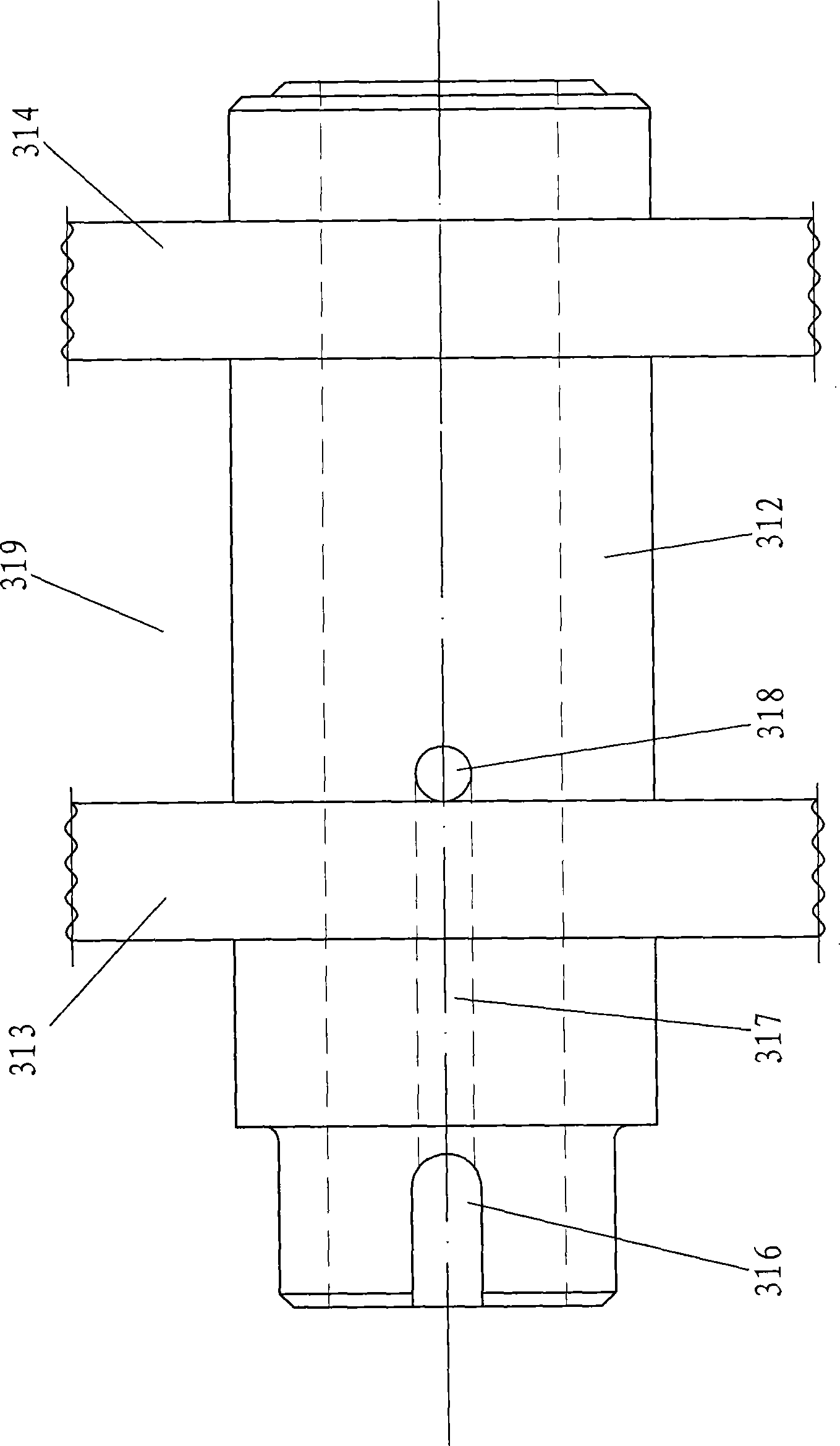

[0016] The magnetorheological shock absorber 3 includes a hydraulic cylinder 31 and a coil 32 arranged in the hydraulic cylinder 31. The hydraulic cylinder 31 includes a cylinder barrel 311 and a piston rod 312. The space between the piston rod 312 and the cylinder barrel 311 is filled with magnetorheological shock absorbers. liquid. The magnetorheological fluid is injected through two holes on the bottom plate 7, and the two holes are sealed by a tapered pipe thread hexagon socket plug 71. The joint between the piston rod 312 and the cylinder 311 is sealed by an O-ring 315 , and the spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com