Intelligent circulation anti-icing method for transmitting current by split lead

A technology for splitting wires and transmitting current, which is applied in the installation of cables, overhead lines/cable equipment, and devices for maintaining the distance between parallel conductors. The effect of transmitting electric current and preventing icing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0046] The anti-icing method of utilizing split wires to transmit current intelligent circulation in this embodiment includes the following steps:

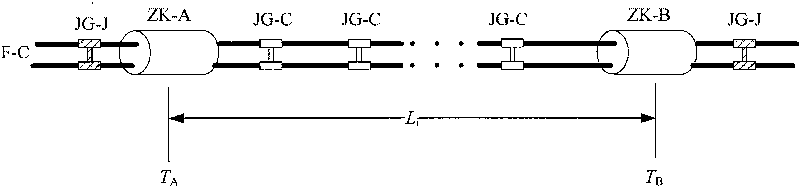

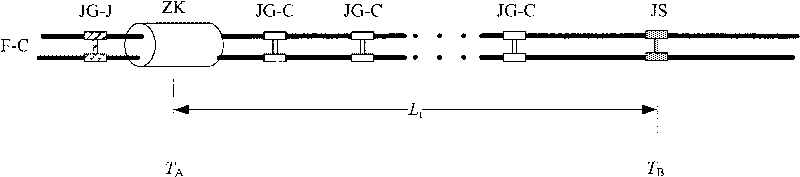

[0047] 1) In the transmission line where the split conductor needs to be anti-icing (ie, the anti-icing section line), use insulating spacers instead of conventional spacers, so that the sub-conductors of the split conductors in the line span that require anti-icing are mutually Insulation, set a control device at the jumper position of the tension tower at the sending end of the line span that requires anti-icing, and set a collector device at the receiving end, the collector device is a control device or a collector spacer;

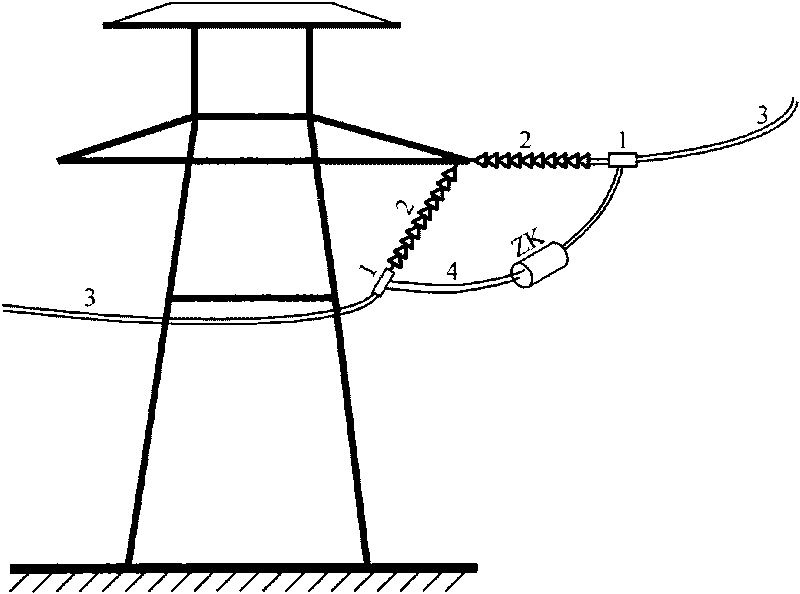

[0048] see figure 1 , the control device is set at the jumper position of the strain tower, in the figure, 1 is a jumper clamp, 2 is an insulator string, 3 is a spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com