HEPA filter unit

A high-efficiency air filtration, high-efficiency filter technology, applied in the directions of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problem of unfavorable biosafety management, difficult to meet laboratory biosafety requirements, high-efficiency air filter in-situ Disinfection and leak detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

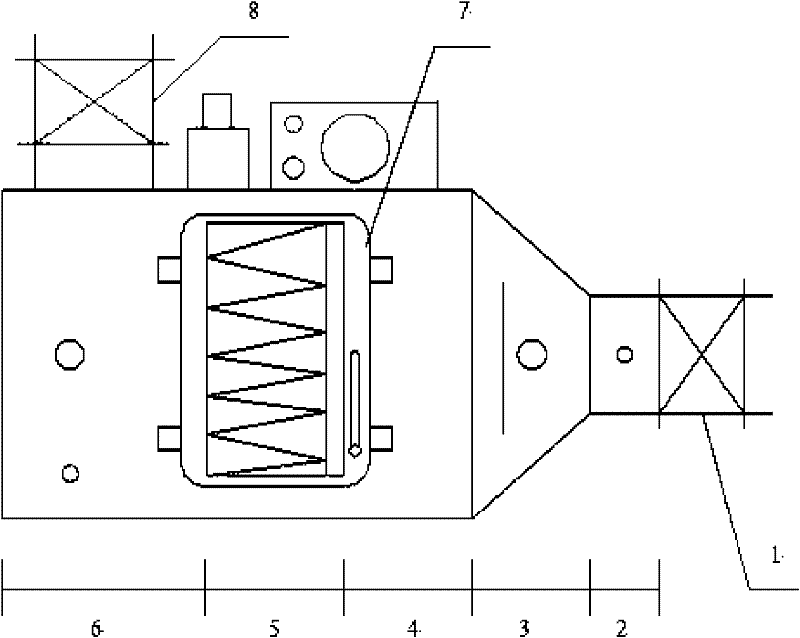

[0032] Such as figure 1 As shown, the present invention consists of a closed end valve 1, an aerosol detection section 2, a mixing section 3, an upstream sampling section 4, a filter installation section 5, a scanning leak detection section 6, a closed door 7, and a top closed valve 8. composition. During the operation, the airtight valves 1 and 8 are in an open state; during the disinfection process, the airtight valves 1 and 8 and the airtight door 7 are in a closed state to avoid spillage of the disinfectant.

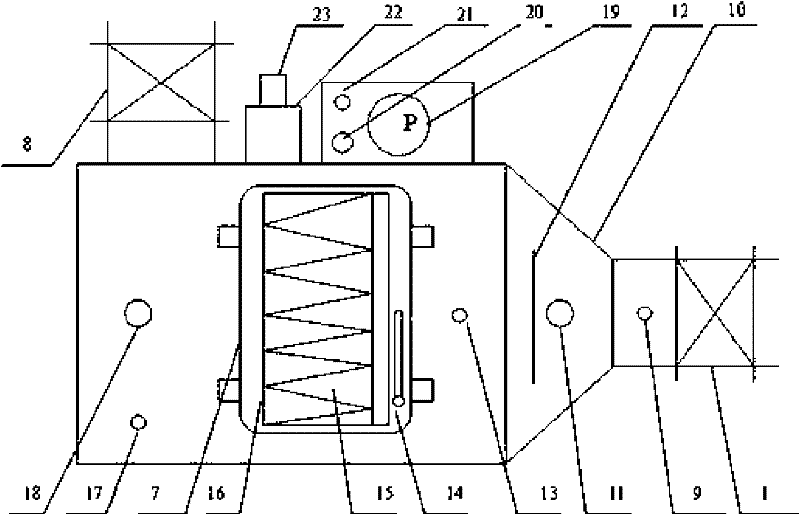

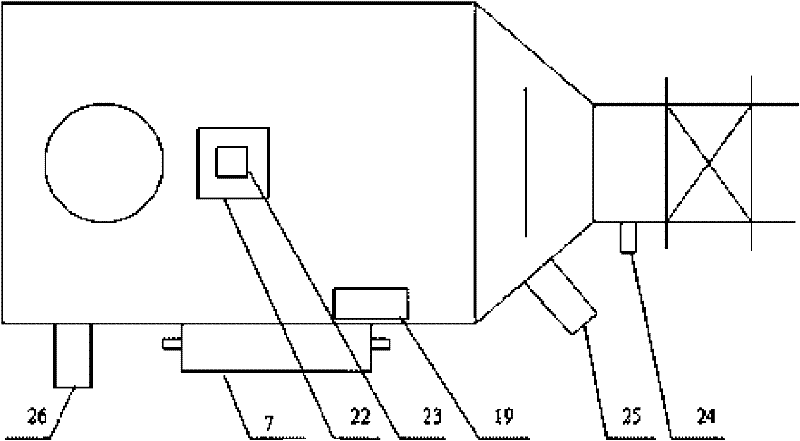

[0033] Such as figure 2, As shown in 3 and 4, the detection aerosol generation section 2 is connected to the airtight valve 1 and the mixing section 3, and the detection aerosol generation section is provided with a dust-generating port 9, and the dust-generating port is externally connected to a quick-plug interface 24. The mixing section 3 is composed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com