Steel rail rolling method

A technology of rail and rough rolling, applied in the field of rail rolling, can solve the problems of uneven wear degree of rolls, reduce production efficiency, serious roll wear, etc., and achieve the effect of shortening the development cycle and improving the success rate of development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

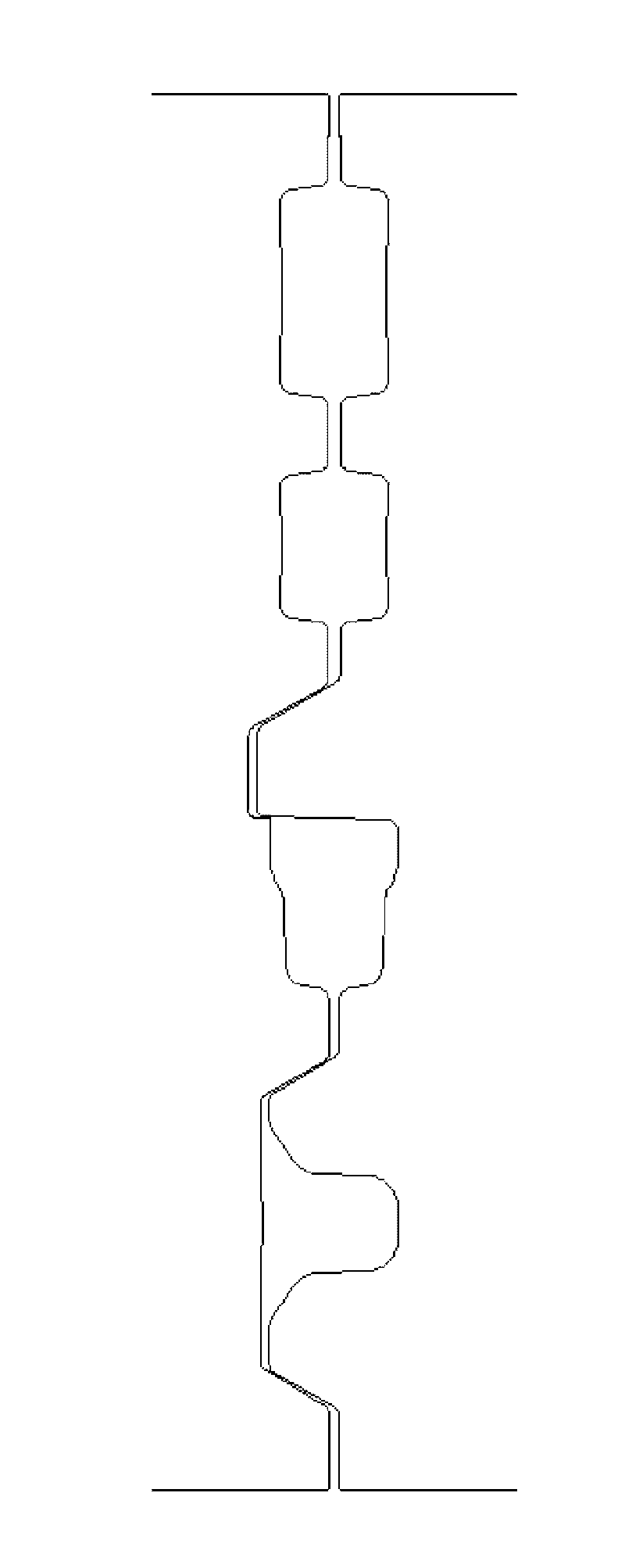

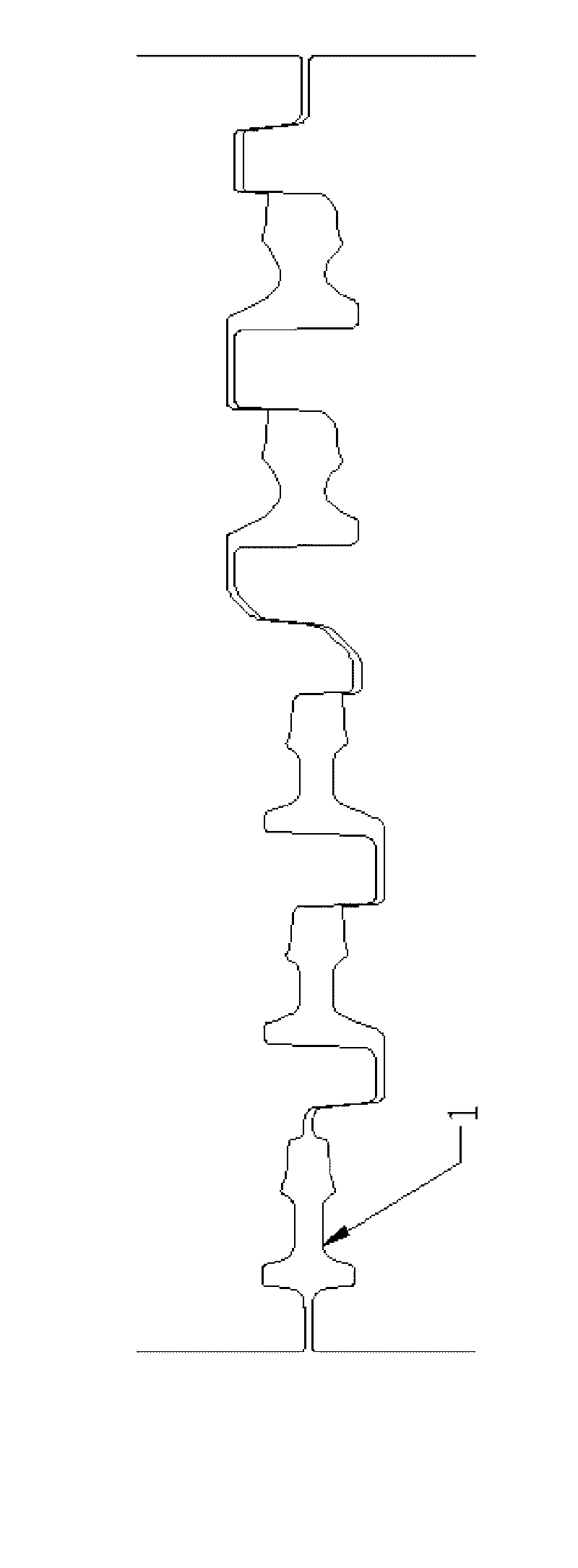

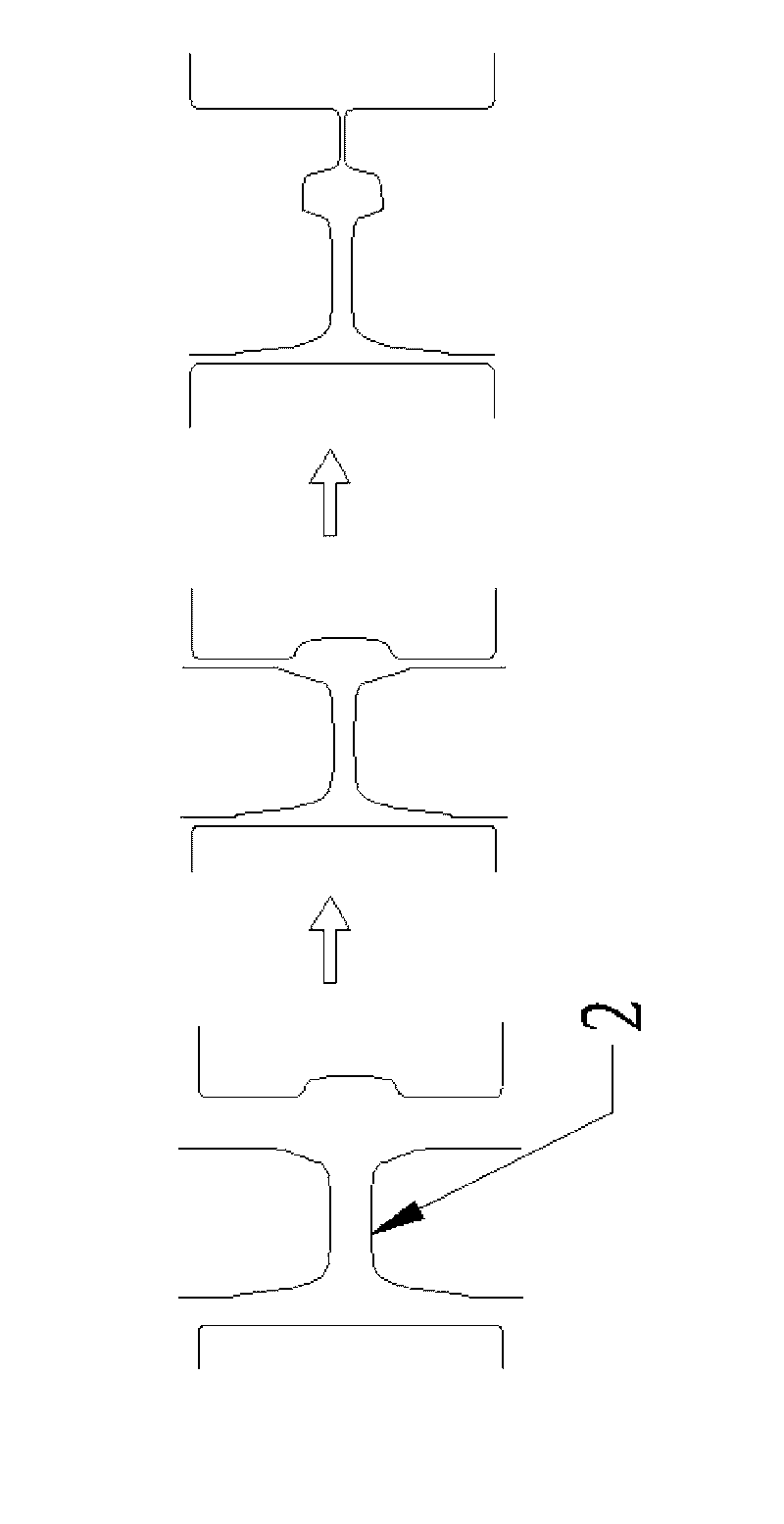

Image

Examples

Embodiment

[0050] The production specifications of a factory (bottom width×rail height×abdominal width×waist thickness, unit of size) are GB60 (150×176×97×16.5, mm),

[0051] UIC60 (150×172×89.5×16.5, mm),

[0052] 136RE (152.4×185.74×106.36×17.46, mm),

[0053] 115RE (139.7×168.3×96.84×15.88, mm),

[0054] GB75 (150×192×104.4×20, mm)

[0055] The five kinds of rails of the present invention adopt the rail rolling method of the present invention, that is, the rolling process in the BD area is designed with GB60 as the standard, and the remaining four varieties are applied to the rolling process in the BD area of the GB60 rail, and the specifications and sizes of each variety produced are It fully complied with the requirements of the standard, and the abdominal cavity was filled well. At the same time, there were no folding defects at the joints of the legs and waist, and the joints of the head and waist.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com