Method of forming a one piece component

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention may be more readily understood by reference to the following description taken in conjunction with the accompanying drawings.

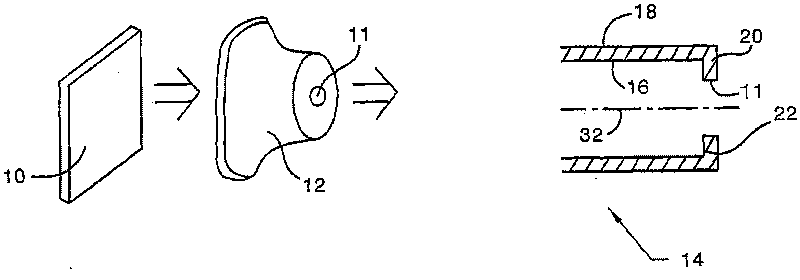

[0027] Referring now to the accompanying drawings, figure 1 Shown is a workpiece 10, preferably a plate, a section of round bar, or a coil of carbon steel, formed into an elongated cup shape 12 having a central bore 11 by conventional cold forging, hot forging or drawing methods . After annealing the cup-shaped preform 12 to soften the material so that the preform 12 is less brittle and relieves internal stresses, the cup-shaped preform 12 is processed by various methods, including by a spin forming operation, to manufacture A net shape preform 14 having an inner surface 16 , an outer surface 18 and an end 20 partially closed by a radial flange 22 .

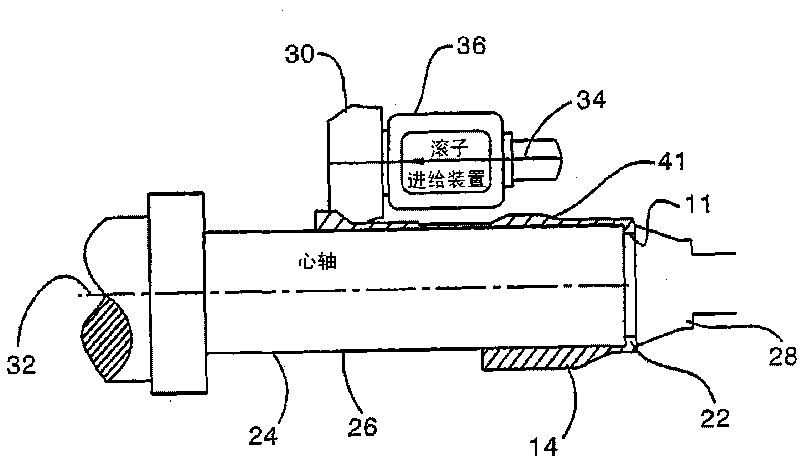

[0028] figure 2 The illustrated spin forming process uses a mandrel 24 having an outer surface 26 . The net shape preform 14 is fitted over the mandrel and is secured at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com