Hyperbranched polymer template material and application thereof in preparing organic nanoparticles

A technology of hyperbranched polymers and hyperbranched polyesters, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of hyperbranched polymers that have not been reported in the literature, and achieve low cost, simple process, and dispersed good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

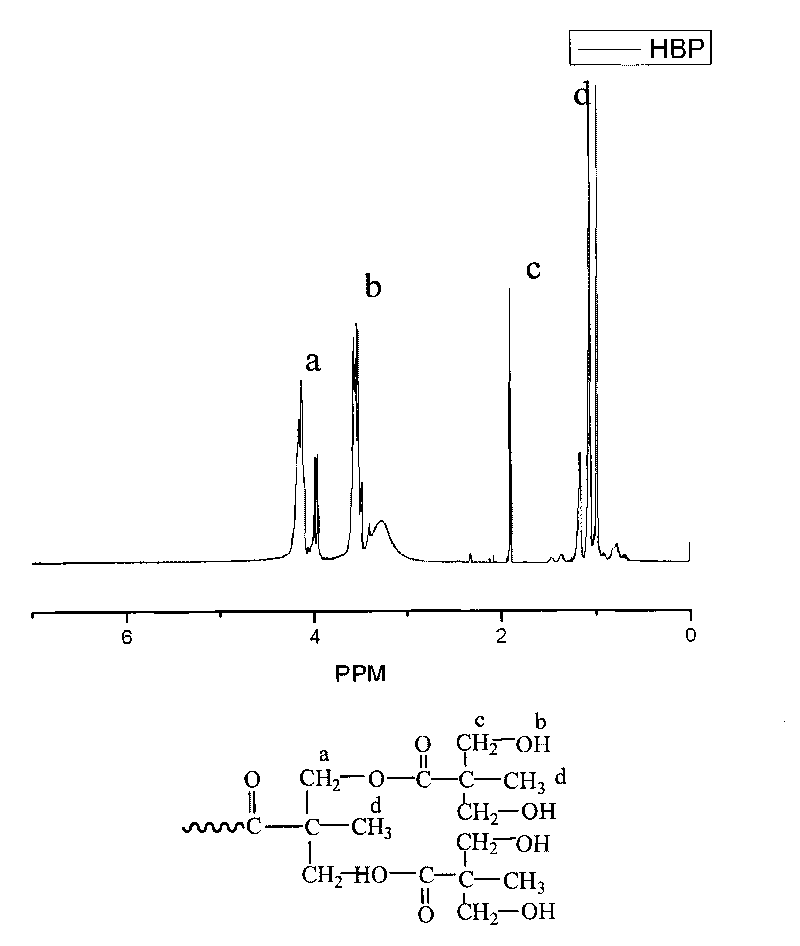

[0027] (1) Preparation of hyperbranched template A: 6.72 g of trimethylolpropane (TMP) was added into a three-necked flask, and dissolved with 100 ml of xylene at 100° C. After the trimethylolpropane (TMP) is completely dissolved, add 21.2g 2,2-dimethylolpropionic acid (DMPA) and 0.2g p-toluenesulfonic acid and heat up to 140°C for about 2 hours; heat up to 150°C and add React 0.1g of p-toluenesulfonic acid for 0.5h, measure the amount of water in the separator close to the theoretical amount of water generated, cool down to 140°C and add 42.4g of 2,2-dimethylolpropionic acid (DMPA), 100ml of xylene and 0.4g of p-toluene React with toluenesulfonate for about 2 hours; heat up to 150°C and add 0.2g p-toluenesulfonic acid to react for 0.5h, measure the amount of water in the water separator close to the theoretical amount of water generated; cool down to 140°C and add 84.8g 2.2-dimethylolpropionic acid (DMPA ), about 100ml of xylene and 0.8g p-toluenesulfonic acid to react for ab...

Embodiment 2

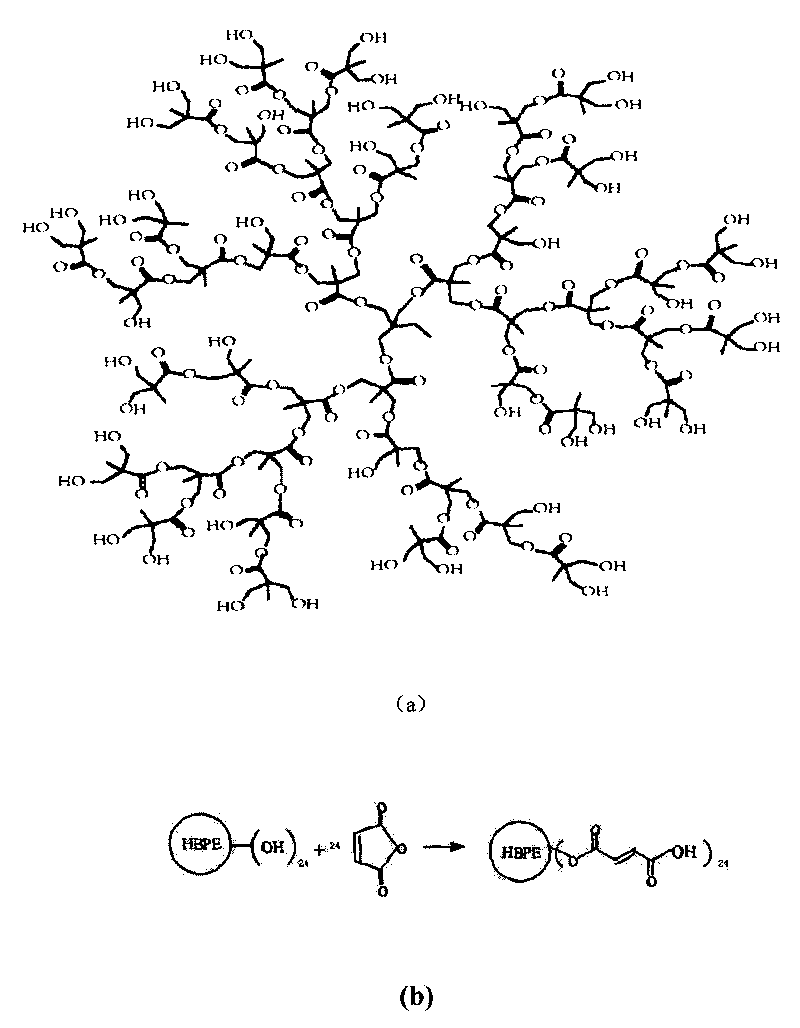

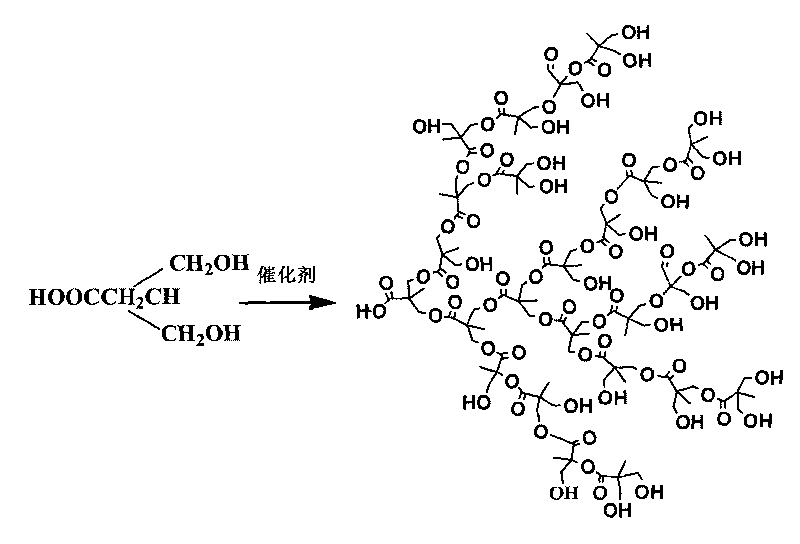

[0032] (1) Preparation of hyperbranched template B: in a four-necked flask equipped with a reflux condenser, agitator, water separator, thermometer, and nitrogen protection, 100 grams of dimethylol propionic acid and a small amount of catalyst p-toluenesulfonate Acid, 200 grams of xylene reacted under reflux for 6-7 hours, when there is no more water distilled out of the water separator, gradually increase the reaction temperature to 150-165 ° C, and further react for 1-2 hours under vacuum to remove the remaining xylene , to obtain light yellow hydroxyl-terminated hyperbranched polyester B. The acid value of the system is lower than 20mgKOH / g. For the reaction formula and structural formula of hyperbranched polyester B, please refer to image 3 .

[0033] (2) Modification of hyperbranched template B: 100 grams of terminal hydroxyl hyperbranched polyester B and 75 grams of succinic anhydride in a four-necked flask equipped with a reflux condenser, agitator, water separator, ...

Embodiment 3

[0037] (1) Preparation of hyperbranched template D: 10.5 grams of neopentyl glycol, 402 grams of dimethylol propionic acid and a small amount of catalyst p-toluenesulfonic acid are added to the four-port reactor, while adding 200 grams of xylene as reflux solvent. Then the reactor was heated in an oil bath at a predetermined temperature of 140° C. After 4 hours of reaction, the solvent and water were distilled off under reduced pressure, and the reaction product was collected to obtain light yellow hydroxyl-terminated hyperbranched polyester D. For the reaction formula and structural formula of hyperbranched polyester D, please refer to Figure 4 .

[0038] (2) Modification of the hyperbranched template D: 100 grams of the obtained hydroxyl-terminated hyperbranched polyester D were dissolved in pyridine, 59 grams of acetic anhydride was added, and stirred at room temperature for 2 hours to obtain a carboxyl-terminated hyperbranched polyester.

[0039] (3) Preparation of orga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com