Underground hole-forming device of hydraulic grab bucket

A technology of hole forming device and hydraulic grab bucket, which is applied in the direction of earth mover/shovel, construction, etc., can solve the problems of slow construction progress, hidden dangers, huge equipment, etc., and achieves a high degree of mechanization, strong adaptability, and processing capacity. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, and this embodiment will further describe the present invention in detail without any limitation to the present invention.

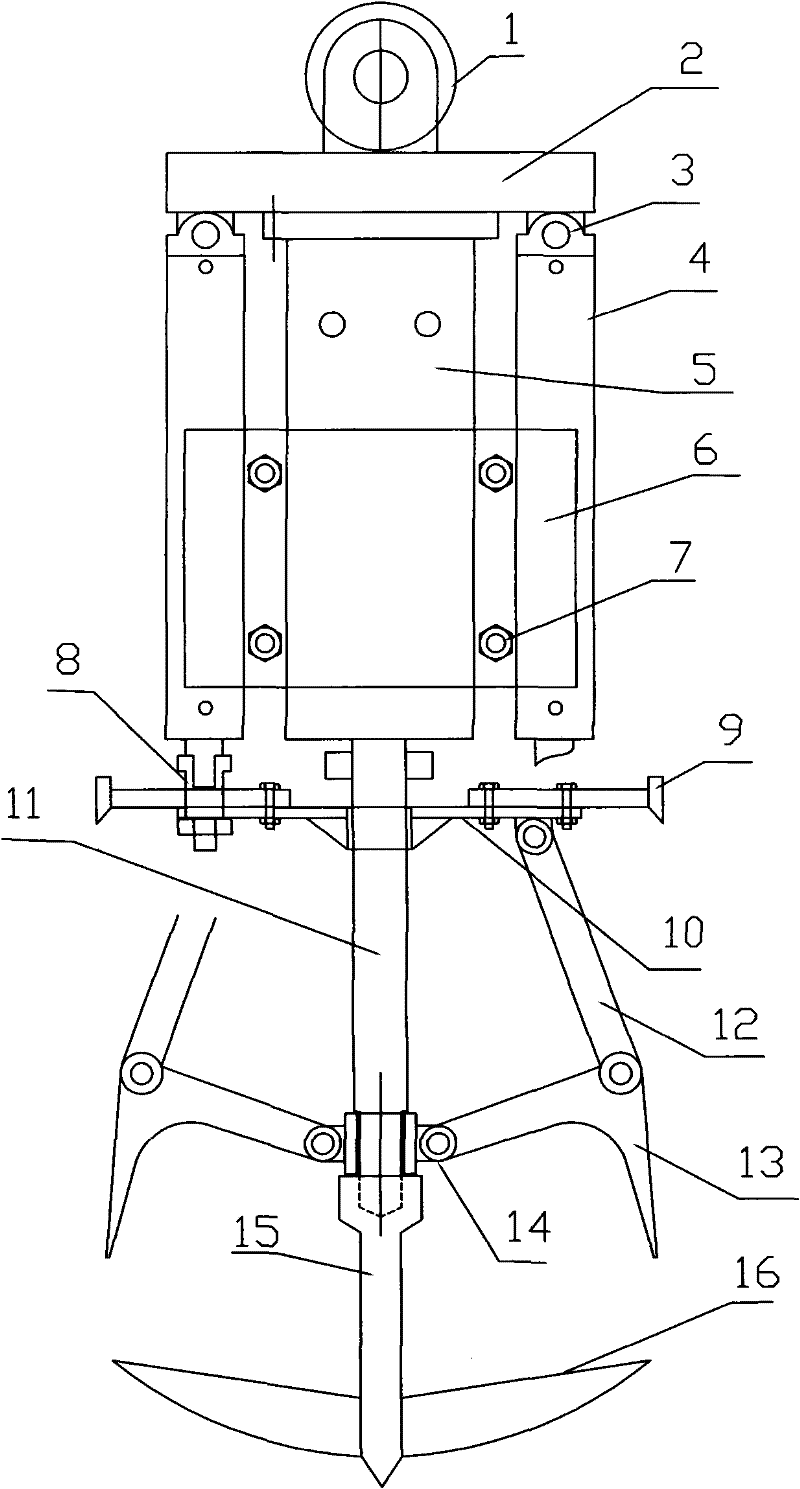

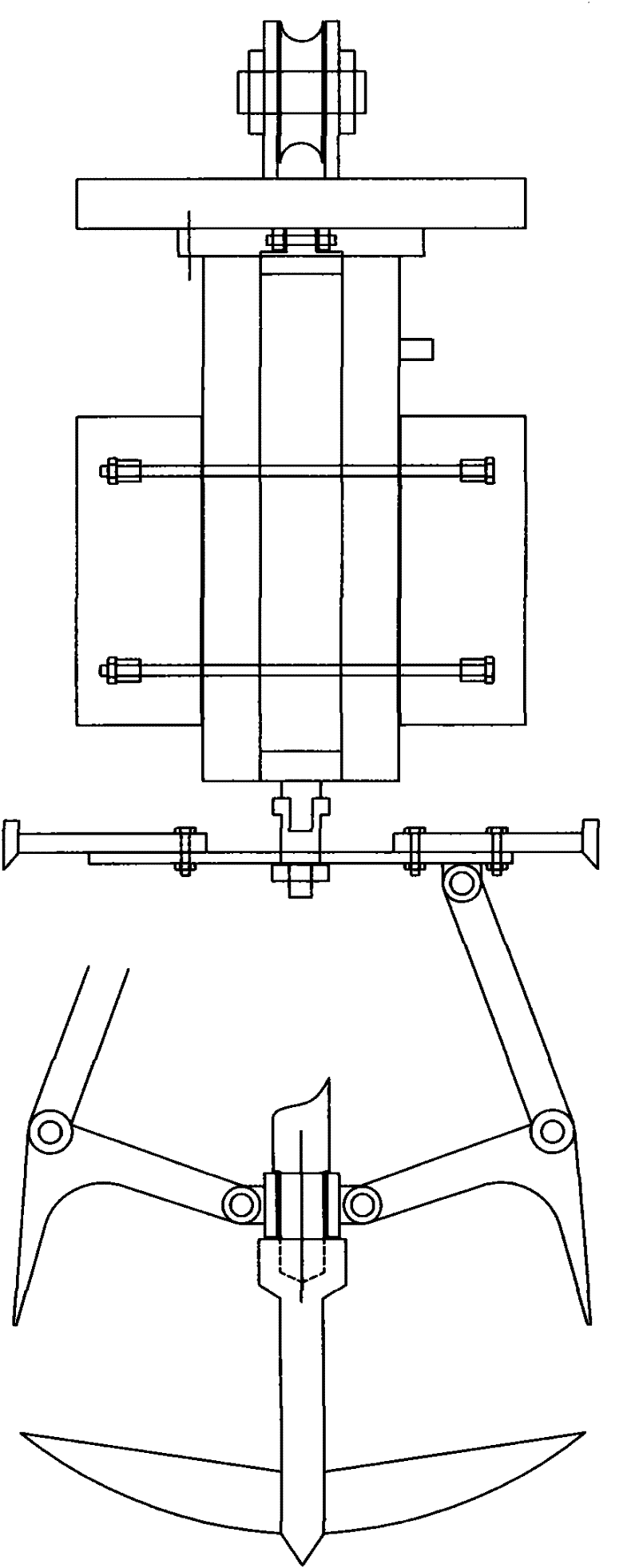

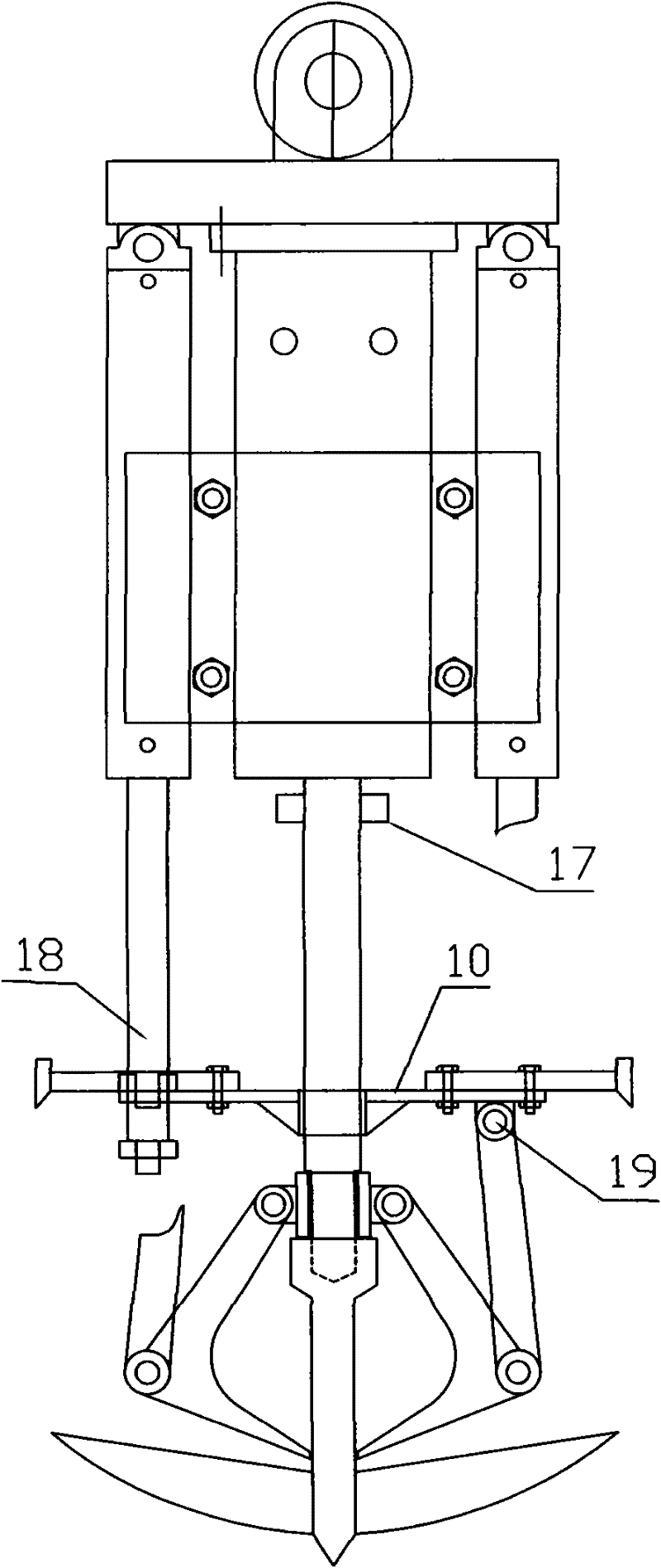

[0030] The present invention mainly consists of wire rope pulley 1, top support plate 2, hydraulic jack connecting pin 3, hydraulic jack 4, breaking hammer 5, counterweight 6, counterweight fixing bolt 7, hydraulic jack and grab tray connector 8, hole reamer 9. Grab tray 10, hydraulic crushing drill upper rod 11, grab support rod 12, grab flap 13, grab connecting rod center sleeve 14, hydraulic crushing drill lower rod 15, cutter head 16, hydraulic crushing drill upper rod sleeve 17 , Hydraulic jack lifter 18, grab tray and grab support rod connection pin hole 19, top support plate connection hole 20, grab tray center sleeve 21, reamer installation hole 22, connector through hole 23, breaker oil Road interface 24, connecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com