Composite thin film anode catalyst of direct methanol fuel cell and preparation method thereof

A methanol fuel cell and composite thin film technology, which is applied in the direction of solid electrolyte fuel cells, battery electrodes, chemical instruments and methods, etc., can solve the problems of limited development and application, catalyst poisoning, high price, etc., and achieve the enhancement of anti-poisoning ability, catalytic Improved ability and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

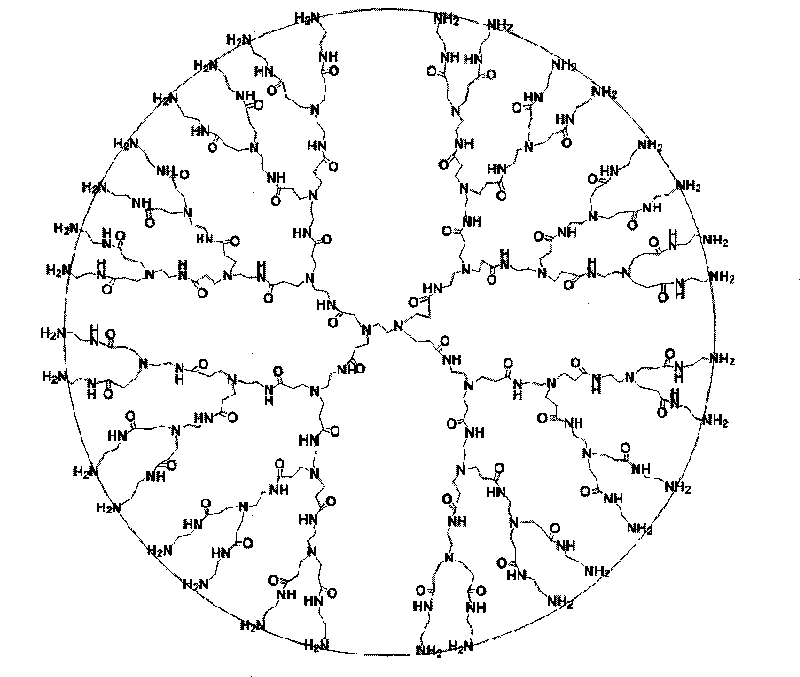

Image

Examples

Embodiment 1

[0021] 1. Cleaning:

[0022] The glassy carbon electrode substrates were sequentially coated with 1.0, 0.3 and 0.05 μm α-Al 2 o 3 powder polishing, and then ultrasonically cleaned in ethanol solution and distilled water for 10 min successively. -1 h 2 SO 4 Control the potential range of -0.25V to 1.25V in the solution for cyclic potential scanning until a stable standard cyclic voltammogram is obtained.

[0023] 2. Cationization:

[0024] Place the cleaned glassy carbon electrode substrate in 5mmol·L -1 Soak in the ethanol solution of p-aminothiophenol for 15 hours, take it out, wash it with distilled water, and dry it with nitrogen to obtain a cationized glassy carbon electrode substrate.

[0025] 3. Film self-assembly:

[0026] Put the cationized glassy carbon electrode substrate in 5mmol·L -1 PMo 12 +H 2 PtCl 6 In the solution, in the potential range of -0.15V ~ 0.7V at 100mV s -1 The scanning speed was scanned for 40 weeks, washed with ethanol solution and dei...

Embodiment 2

[0031] 1. Cleaning:

[0032] The glassy carbon electrode substrates were sequentially coated with 1.0, 0.3 and 0.05 μm α-Al 2 o 3 powder polishing, and then ultrasonically cleaned in ethanol solution and distilled water for 15 min successively. -1 h 2 SO 4 Control the potential range of -0.25V to 1.25V in the solution for cyclic potential scanning until a stable standard cyclic voltammogram is obtained.

[0033] 2. Cationization:

[0034] Place the cleaned glassy carbon electrode substrate in 9mmol·L -1 Soak in the ethanol solution of p-aminothiophenol for 12 hours, take it out, wash it with distilled water, and dry it with nitrogen to obtain a cationized glassy carbon electrode substrate.

[0035] 3. Film self-assembly:

[0036] Put the cationized glassy carbon electrode substrate in 8mmol·L -1 Si 2 Mo 18 +H 2 PtCl 6 In the solution, in the range of potential -0.25 ~ 0.65V at 50mV s -1 Speed scanning for 30 weeks, washed with ethanol solution and deionized wate...

Embodiment 3

[0040] 1. Cleaning:

[0041] The glassy carbon electrode substrates were sequentially coated with 1.0, 0.3 and 0.05 μm α-Al 2 o 3 powder polishing, and then ultrasonically cleaned in ethanol solution and distilled water for 5 min successively. -1 h 2 SO 4 Control the potential range of -0.25 to 1.25V in the solution for cyclic potential scanning until a stable standard cyclic voltammogram is obtained.

[0042] 2. Cationization:

[0043] Place the cleaned glassy carbon electrode substrate in 3mmol·L -1 Soak in the p-aminothiophenol ethanol solution for 20 hours, take it out, wash it with distilled water, and dry it with nitrogen to obtain a cationized glassy carbon electrode substrate.

[0044] 3. Film self-assembly:

[0045] Put the cationized glassy carbon electrode substrate in 10mmol·L -1 SiW 12 +H 2 PtCl 6 In the solution, in the potential range of -0.3 ~ -0.9V at 80mV s -1 The scanning speed was scanned for 40 weeks, and then washed with ethanol solution and d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap