Ballast tank circulation management system

A circulation system and ballast tank technology, applied in the field of level systems, can solve problems such as uneven circulation and inconsistent water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

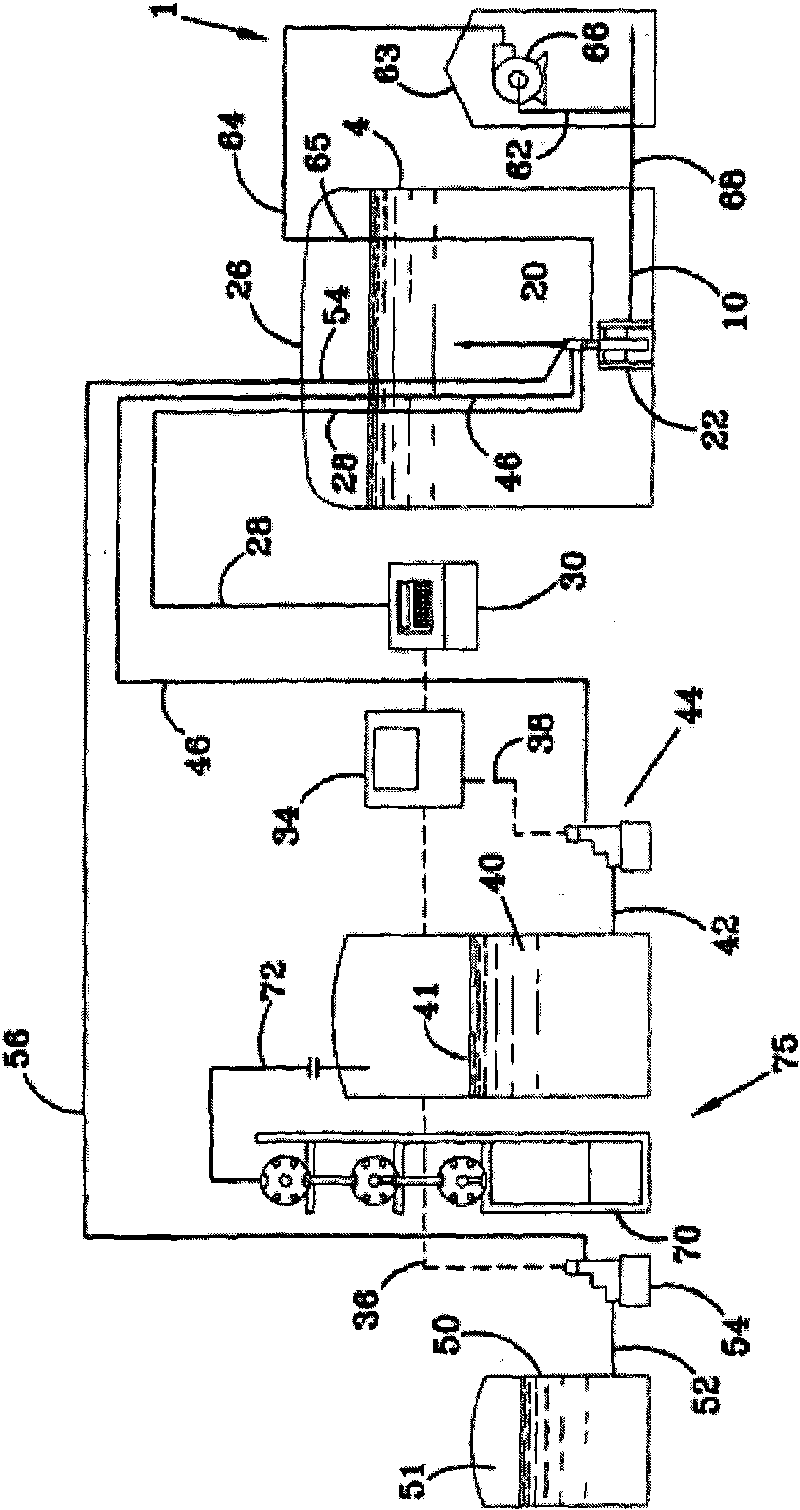

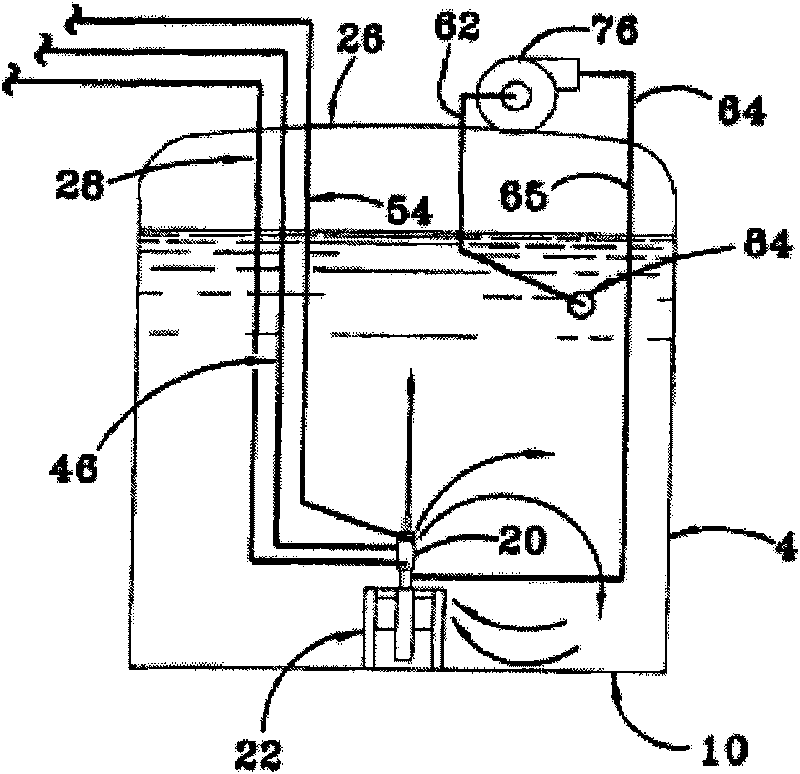

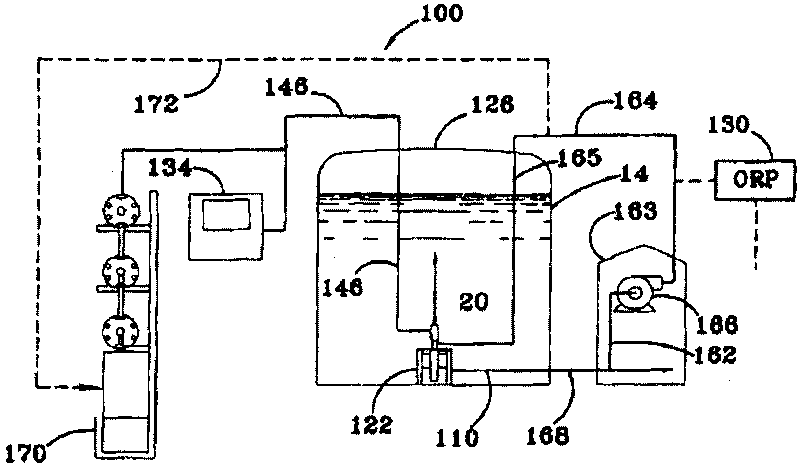

[0017] of the present invention figure 1 A ballast tank circulation system for one or more water storage and treatment ballast tanks 10 is shown, having a pump 66 external to the ballast tank 10 . One advantage of the external pump 66 is that it facilitates the management and repair of the ballast tank system 1 . An external pump 66 can be installed quickly and easily. One embodiment of the present invention requires that exactly two connectors hook into the pump system 66 . Repairs are easy due to easy access to pump equipment. The ballast tank circulation system 1 also includes one or more injectors 20 located within the ballast tank 10 such that the injectors 20 receive pressurized water from the external pump 66 and emit the water as high pressure jets. Eductors are used to increase the motive force of the water and thus the recirculation of water and chemicals within the ballast water. As the injector draws in the pressurized water from the external pump 66, it also d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com