Evaporating heat exchanger

A technology of evaporative heat exchanger and tube box, which is applied in the direction of heat exchanger type, indirect heat exchanger, lighting and heating equipment, etc., can solve the problems of low heat exchange efficiency, increased system complexity, and increased production cost, etc. Achieving large capacity, reasonable and simple design, and achieving the effect of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

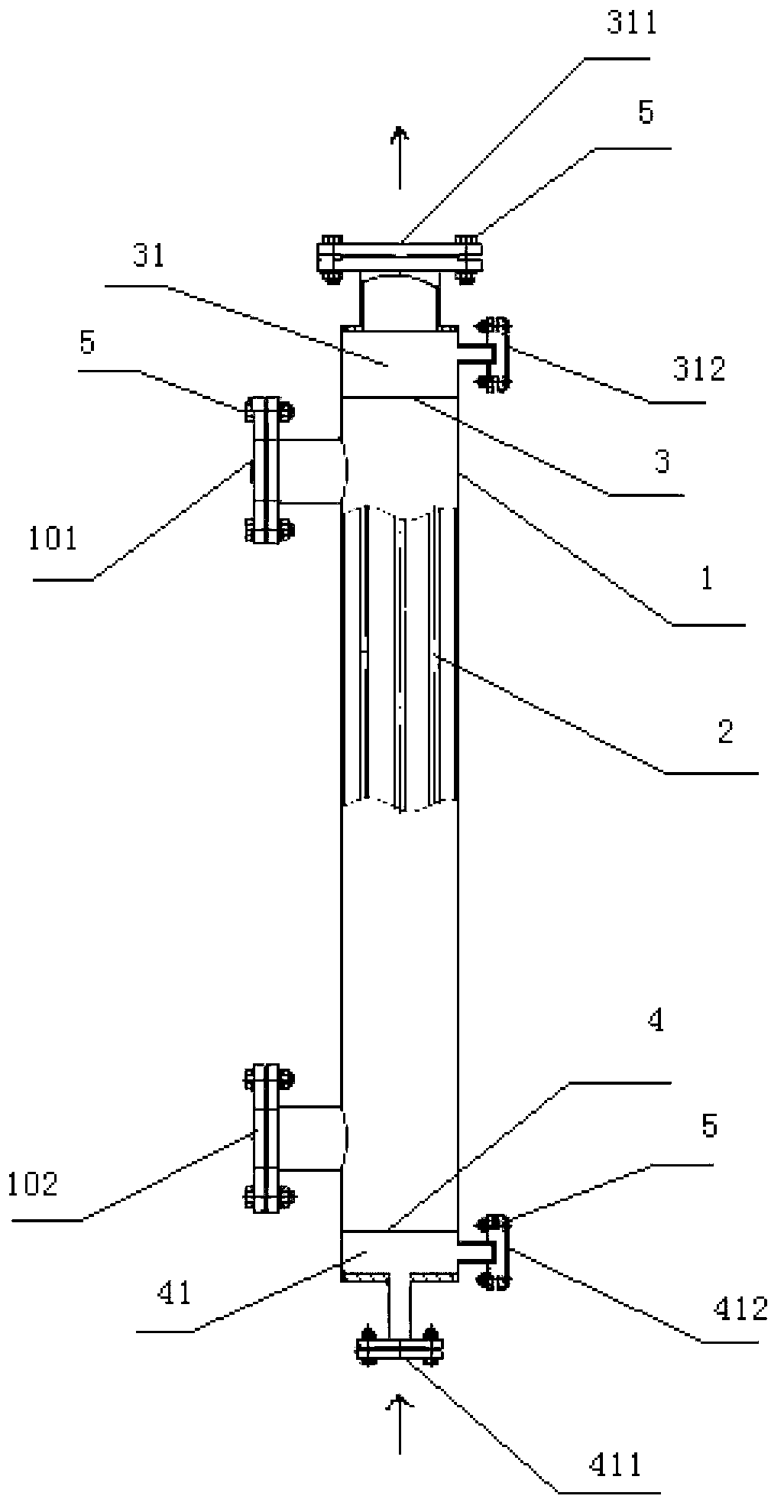

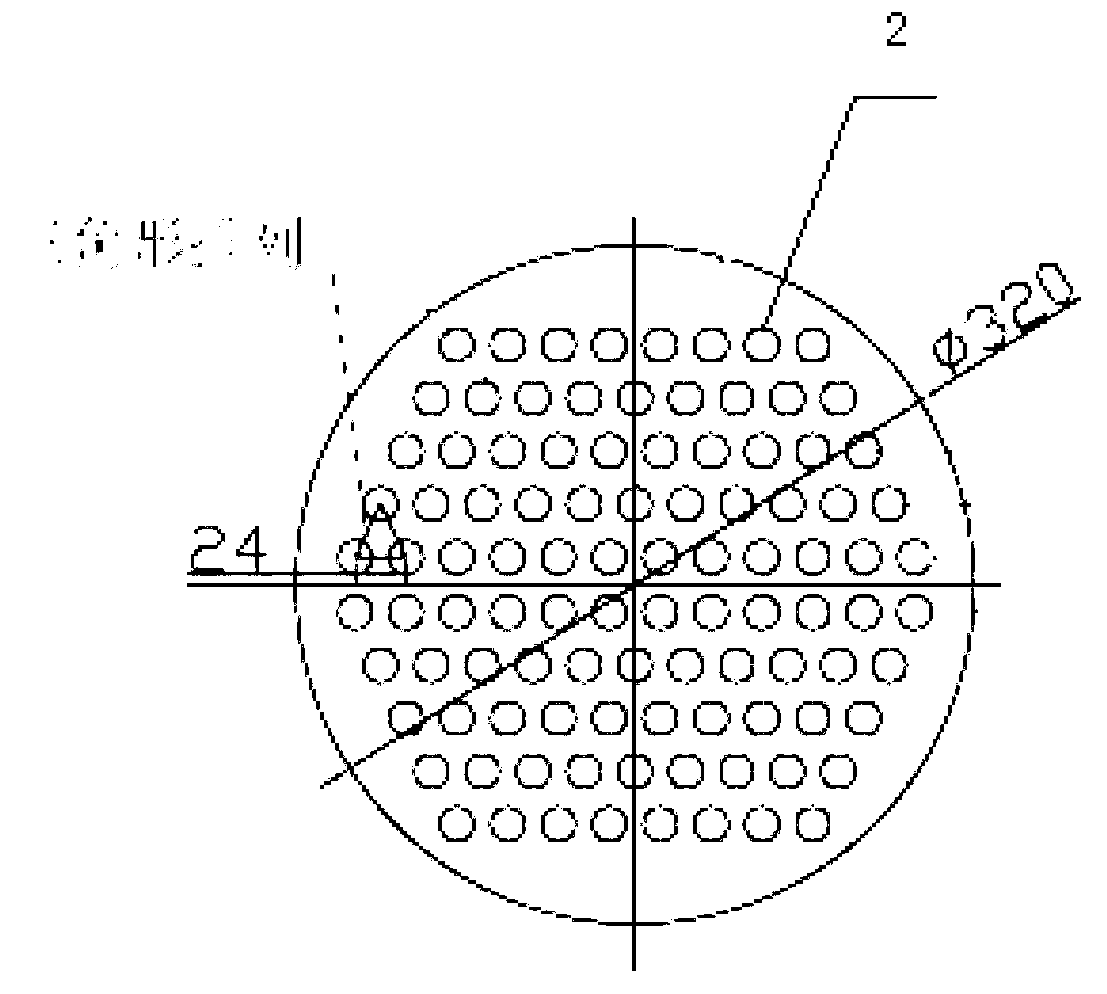

[0019] see figure 1 and figure 2 , the evaporative heat exchanger of the present invention includes a shell 1, 100 copper tubes 2, a top tube sheet 3 and a bottom tube sheet 4, wherein:

[0020] The shell 1 is cylindrical, its height is 1500mm, and its pipe diameter is Φ320mm×2.5mm, indicating that the diameter (that is, the diameter of the cross-sectional circle of the shell 1) is 320mm, and the thickness (that is, the thickness of the side wall of the shell 1) is 2.5mm, for the convenience of description, the meaning of the pipe diameter below is similar;

[0021] The top tube plate 3 divides the top part of the shell 1 into a top tube box 31, and the height of the top tube box 31 is 150 mm;

[0022] The bottom tube plate 4 divides the bottom part of the shell 1 into a bottom tube box 41, and the height of the bottom tube box 41 is 150mm;

[0023] The top of the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com