Resin composition

A resin composition and compound technology, applied in the direction of non-polymer organic compound adhesives, adhesive types, adhesive additives, etc., can solve the problem of large deviation of properties, etc., to reduce the deviation of properties and properly cure Time, productivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

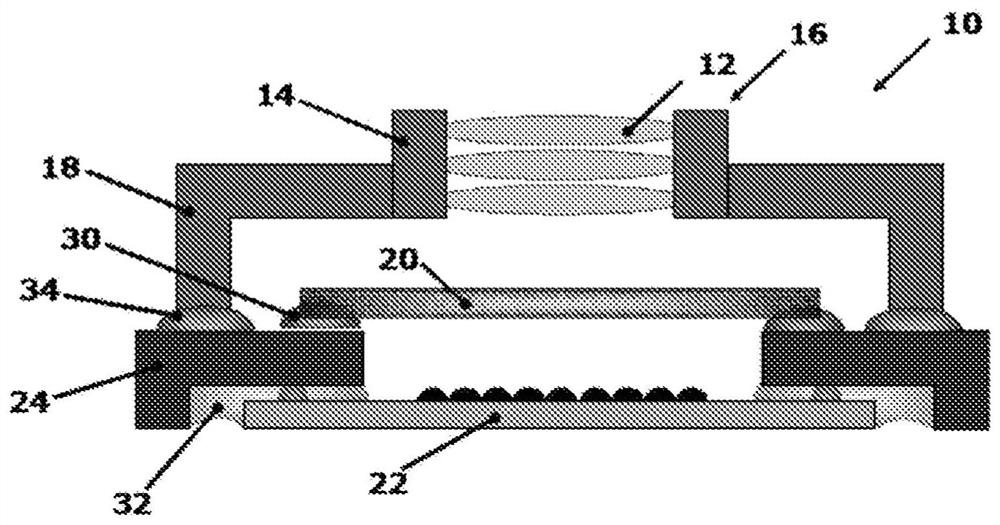

Image

Examples

Embodiment 1~16 and comparative example 2、3

[0183] Component (c) or (c') was added dropwise to 1.00 g of component (a) in a polypropylene microtube so that the molar ratio to component (a) became the value shown in Table 3, and mixed. Component (b) was added to the obtained mixture so that the molar ratio with respect to component (a) might become the value shown in Table 3, and it was shaken and mixed with the vortex mixer again, and the resin composition was obtained.

[0184] The time (gel time) until the above-mentioned resin composition substantially loses fluidity from the time of completion of this mixing was measured at room temperature (25 degreeC). Table 3 shows the gel time (unit: min) of each resin composition together with the molar ratio of each component in the resin composition. In addition, in Table 3, the mass ratio (unit: mass ppm) of components (c) and (c') to the whole resin composition is also described together.

[0185] "Practically loses fluidity" means that when the above-mentioned resin compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com