Automatic stacking method and device for corrugated boards

A corrugated cardboard and stacking technology is applied in the field of automatic corrugated cardboard stacking methods and devices, which can solve the problems of stacking cardboard dumping, limiting the number of stacked cardboards, etc., so as to eliminate gaps, reduce downtime adjustment time and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

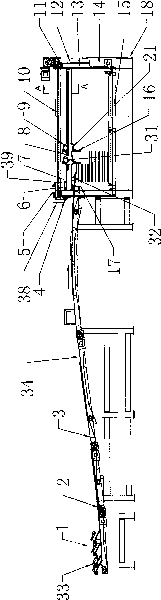

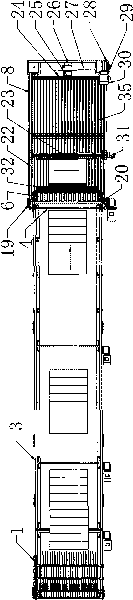

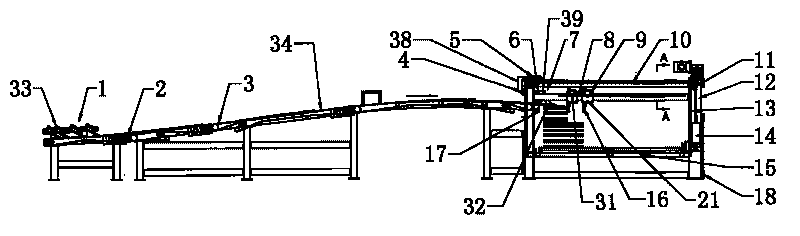

[0016] Attached below figure 1 And attached figure 2 To further illustrate the present invention, the preferred embodiment of the present invention is: the automatic stacker for corrugated cardboard described in this embodiment: when the corrugated cardboard pressed by the press assembly 1 passes through the conveying assembly 3, the conveying assembly The ejector device 2 in 3 separates the corrugated cardboard under the drive of the cylinder, and the separated corrugated cardboard is driven by the conveyor belt into the hanging cage assembly 12, and the hanging rail assembly 15 stops at the initial stage driven by its motor. The receiving position collects the corrugated cardboard, and the cardboard assembly 7 combs the corrugated cardboard that enters the hanging cage assembly 12, and the carded corrugated cardboard falls on the hanging rail assembly 15 after being sorted by the paper retaining assembly 9, when the corrugated cardboard is collected When the height reaches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com