Application of methylnaphthalene in lowering viscosity of thickened oil

A technology of heavy oil viscosity and methyl naphthalene, applied in the directions of drilling compositions, production fluids, wellbore/well components, etc., can solve the problems of reducing the viscosity of heavy oil, not disclosing the viscosity of heavy oil, and not disclosing information such as , to reduce the viscosity of heavy oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

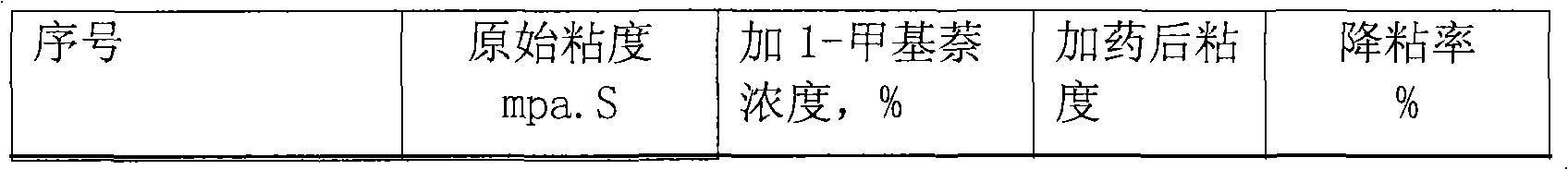

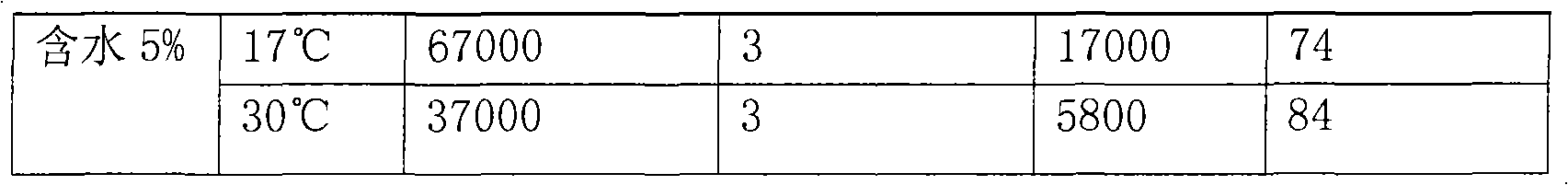

[0122] Add 1-methylnaphthalene to the heavy oil that is mined or / and exported to reduce the viscosity of the heavy oil, thereby reducing the flow resistance of the heavy oil, and making the heavy oil flow smoothly;

[0123] Tests show that: adding the 1-methylnaphthalene to the heavy oil can effectively reduce the viscosity of the heavy oil (see the test data in Table 3 of the test results);

Embodiment 2

[0125] Repeat Example 1, except that: in order to prevent the 1-methylnaphthalene from generating crystals, solids or solidification in a low temperature environment, fusel oil is added to the 1-methylnaphthalene;

[0126] The fusel oil refers to any one of fusel oil from the by-product of alcohol production by fermentation and fusel oil from the by-product of butadiene production by alcohol, or a mixture of them in any ratio;

[0127] Any one of the fusel oils is a commodity or can be purchased from the market;

[0128] The added fusel oil ensures that the 1-methylnaphthalene is always liquid in a low temperature environment, and does not produce crystals, solids or solidification.

Embodiment 3

[0130] Repeat Example 1, except that: in order to prevent the 1-methylnaphthalene from generating crystals, solids or solidification in a low temperature environment, a special organic solvent is added to the 1-methylnaphthalene;

[0131] The special organic solvent refers to any of alcohols (such as octanol, isoamyl alcohol, etc.), glycol derivatives (such as ethylene glycol butyl ether, diethylene glycol butyl ether, diethylene glycol ethyl ether, etc.) One or a mixture of any two or more of them in any ratio;

[0132] Any one of the special organic solvents is a commodity or can be purchased from the market;

[0133] The added special organic solvent ensures that the 1-methylnaphthalene is always liquid in a low temperature environment, and does not produce crystals, solids or solidification.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com