Completed well body structure with temporary plugging function screen pipe and well completion method for injecting cement on top

A technology of wellbore structure and graded cementing device, which is applied in the direction of wellbore/well components, earthwork drilling, production fluid, etc., which can solve problems such as mud cake clogging, prevent clogging, simplify operation methods, and reduce the number of trips Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

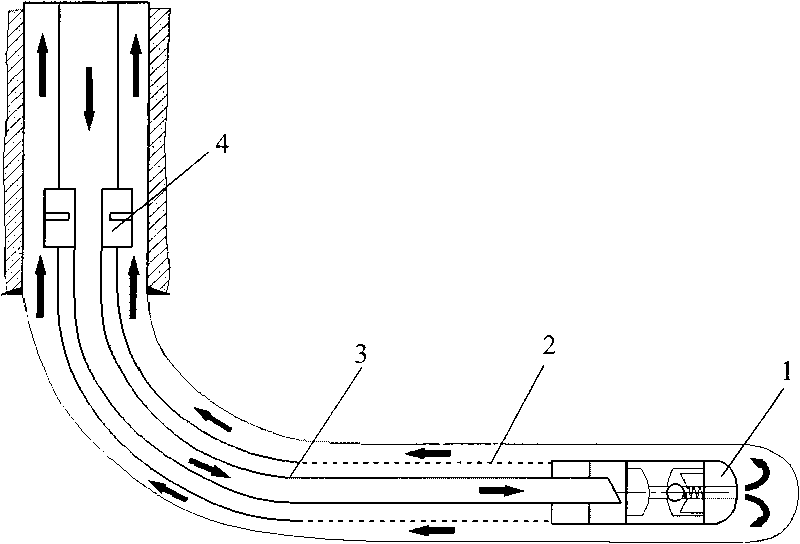

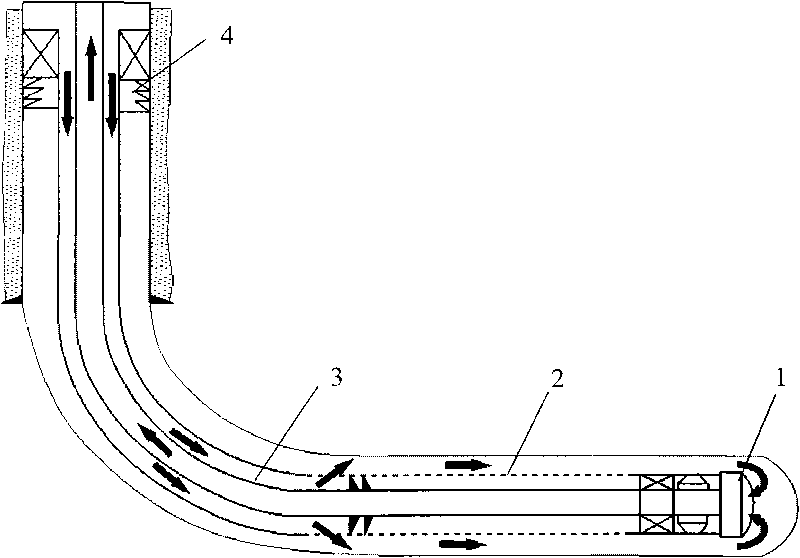

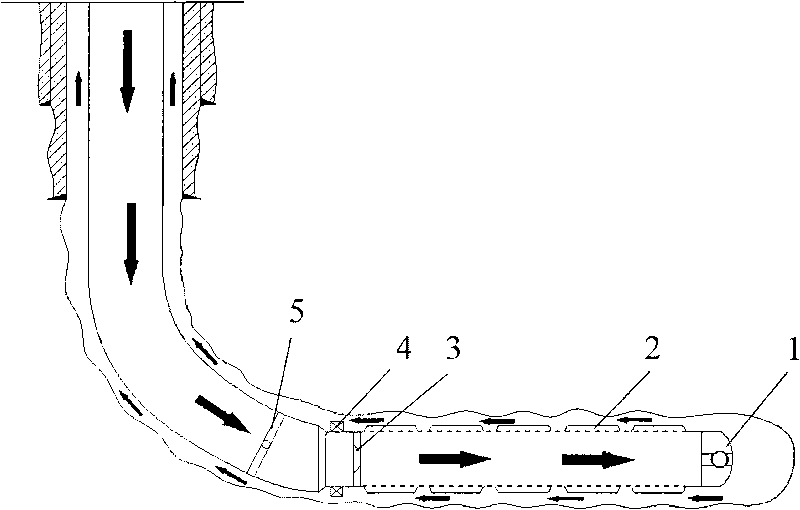

[0045] Well completion well body structure form of the present invention adopts image 3 In the structural form shown, a multifunctional well flushing valve 1, a screen pipe 2, a blind plate 3, an outer packer 4 and a graded cementing device 5 are sequentially connected from bottom to top to the wellhead. The important improvement of the present invention lies in The completely new structural design of the screen pipe 2 realizes the well completion method of the present invention, which is greatly superior to the well completion method of the prior art.

[0046] see Figure 4 , the screen body 2 with temporary plugging function of the present invention is composed of an outer filter sleeve (outer jacket 23, filter layer 22 integration) and an inner center pipe 21. There are a number of oil casing through holes (drilled) that meet the API standard on the center pipe 21. hole), each through hole is connected with a blocking cover 24.

[0047]The blocking cap 24 can be connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com