Laser image module and non-contact type measurement device using same

An image module and laser technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of plastic deformation of curved plate parts, increase the difficulty of precise processing and measurement, and achieve the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Certain embodiments of the present invention will be described in more detail below with reference to the accompanying drawings. In describing the present invention, certain detailed descriptions of related art have been omitted when it was considered that they would unnecessarily obscure the essence of the present invention.

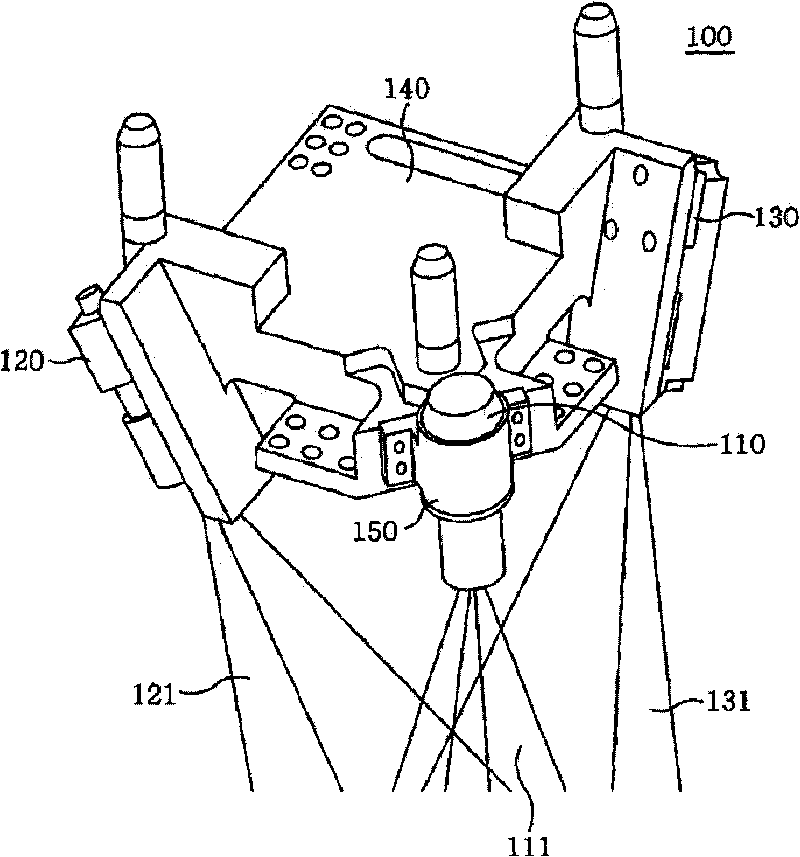

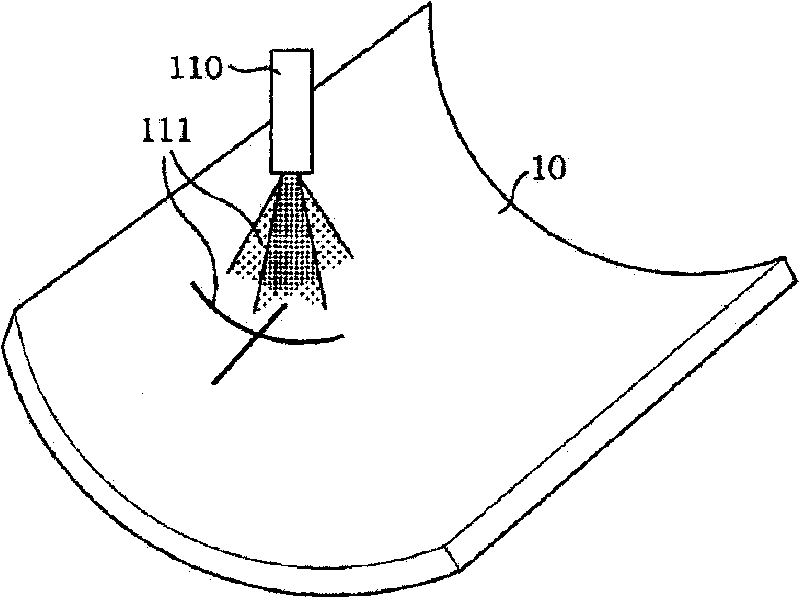

[0035] figure 2 It is a laser imaging module for a non-contact measuring device according to one aspect of the present invention. Such as figure 2 As shown, the laser imaging module 100 according to one aspect of the present invention includes: a laser generator 110 for irradiating a cross-shaped laser beam 111 onto the object to be measured; a pair of cameras 120 and 130 for irradiating the object to be measured and a single mount 140 on which the laser generator 110 and the pair of cameras 120, 130 are mounted as a whole. The laser generator 110 may be installed in the housing 150 , which is integrally connected to the fixing member 140 su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com