Manufacturing method of monolithic integrated pressure sensor

A technology of pressure sensor and monolithic integration, which is applied in semiconductor/solid-state device manufacturing, measurement of the property and force of applied piezoresistive materials, electrical components, etc., and can solve compatibility difficulties, monolithic integration difficulties, and easy-to-contaminate IC processes, etc. problem, to achieve the effect of solving the compatibility of processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Specific embodiments of the present invention are not limited to the following description. The present invention will be further described now in conjunction with accompanying drawing.

[0065] The main steps of the inventive method are as follows:

[0066] 1. On the P-type silicon substrate sheet 2, the steps of making the P-type silicon substrate that bipolar analog integrated circuits and varistors are used are as follows:

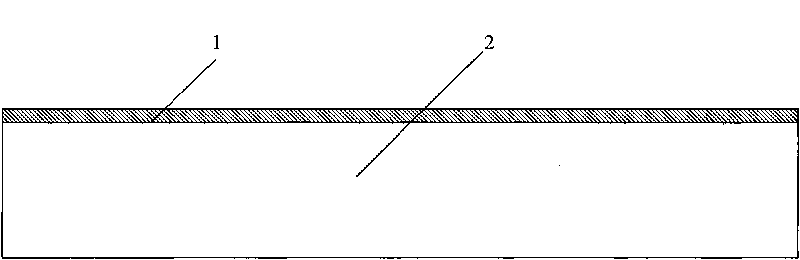

[0067] (1) P-type silicon substrate 2, with crystal orientation, polished on both sides, with a thickness of 400±10 μm and a resistivity of 7-13Ω·cm, cleaned and oxidized, and the thickness of the oxide layer 1 is 0.6±0.05 μm, such as figure 1 shown;

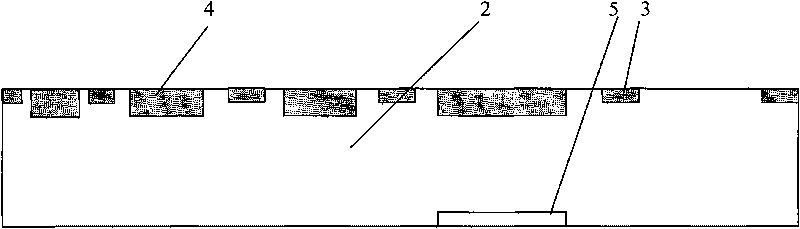

[0068] (2) photoetching N+ buried layer region 3;

[0069] (3) Adhesive arsenic injection, dose 6E15 / cm 2 , energy 100keV, glue removal;

[0070] (4) photoetching P+buried layer region 4;

[0071] (5) Boron injection with glue, dose 1E15 / cm 2 , energy 60keV, glue removal;

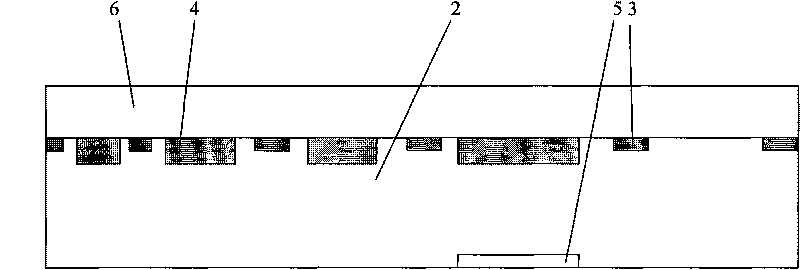

[0072] (6) Usi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com