Vibrating-out rod

A rod body and matching part technology, applied in fishing rods, fishing, applications, etc., can solve problems such as lack of softness, durability, and reduced crimping force, so as to reduce slippage, maintain contact state, and have a good sense of adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

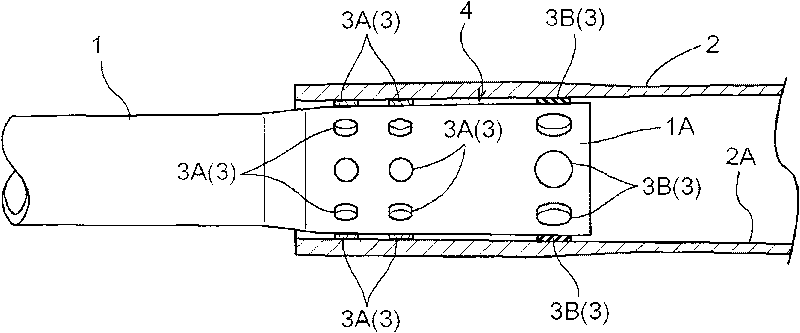

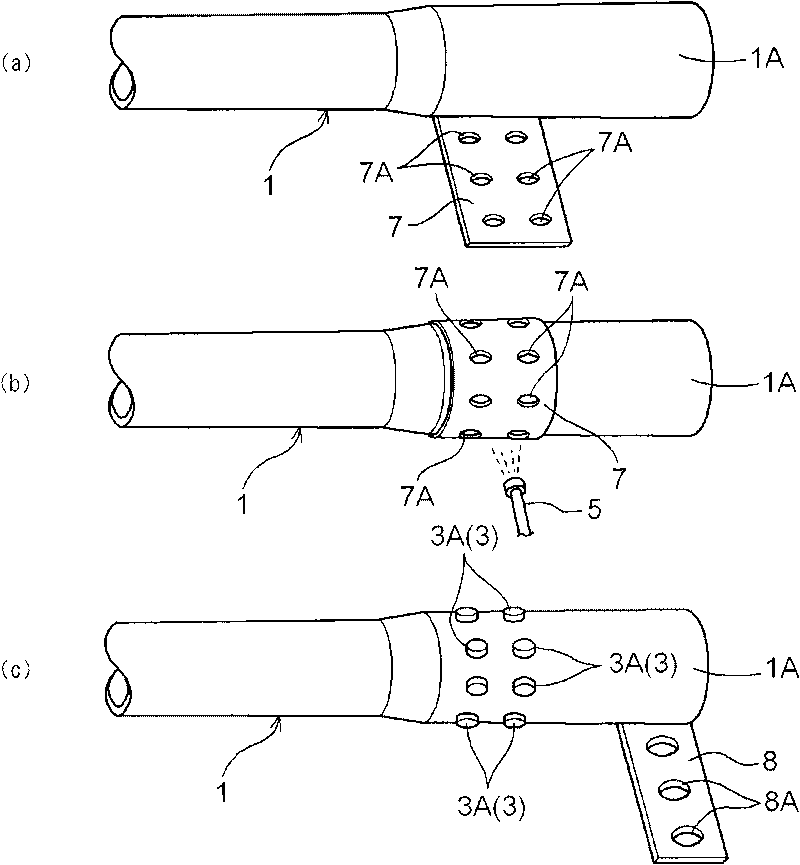

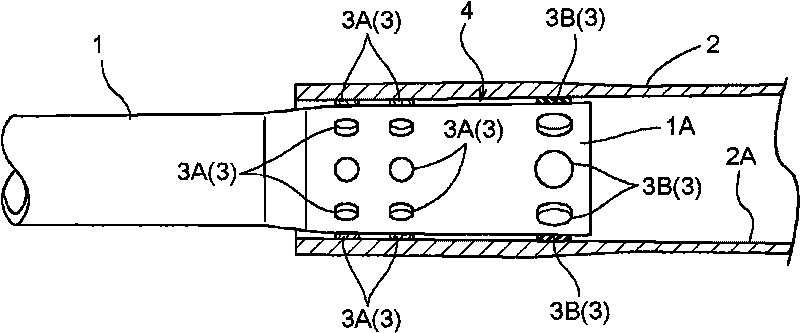

[0035] The structure of the fitting part used for vibrating rods such as catfish rods will be explained. Such as figure 1 As shown, a bulging portion 1A is formed at the rod tail end of the small-diameter rod body 1, and the outer diameter of the bulging portion 1A is formed to be crimped and fitted (in the rod blank stage, the amount of coating is expected to be processed, and This rod blank is processed with a protrusion 3 described later, which is crimped and fitted) on the inner peripheral surface 2A of the rod front end of the large-diameter rod body 2 . The small-diameter rod body 1 can move forward and backward freely relative to the large-diameter rod body 2, and in the pulled out state, the bulging part 1A is crimped on the inner peripheral surface 2A of the ring opening of the front end of the rod, so that the state can be fixed. Shake out the rod. On a part of the bulging portion 1A, a plurality of protrusions 3 formed of a coating material are formed on the entir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com