Electrolytic Ozone Generator with Membrane Electrode

a technology of electrolysis ozone and membrane electrodes, applied in the field of electrolysis ozone generators, can solve the problems of gas and source water leakage, aging of the seal, and the inability to seal, and achieve the effects of stable tightening force, stable function, and low ozone volume of the electrolysis ozone generator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

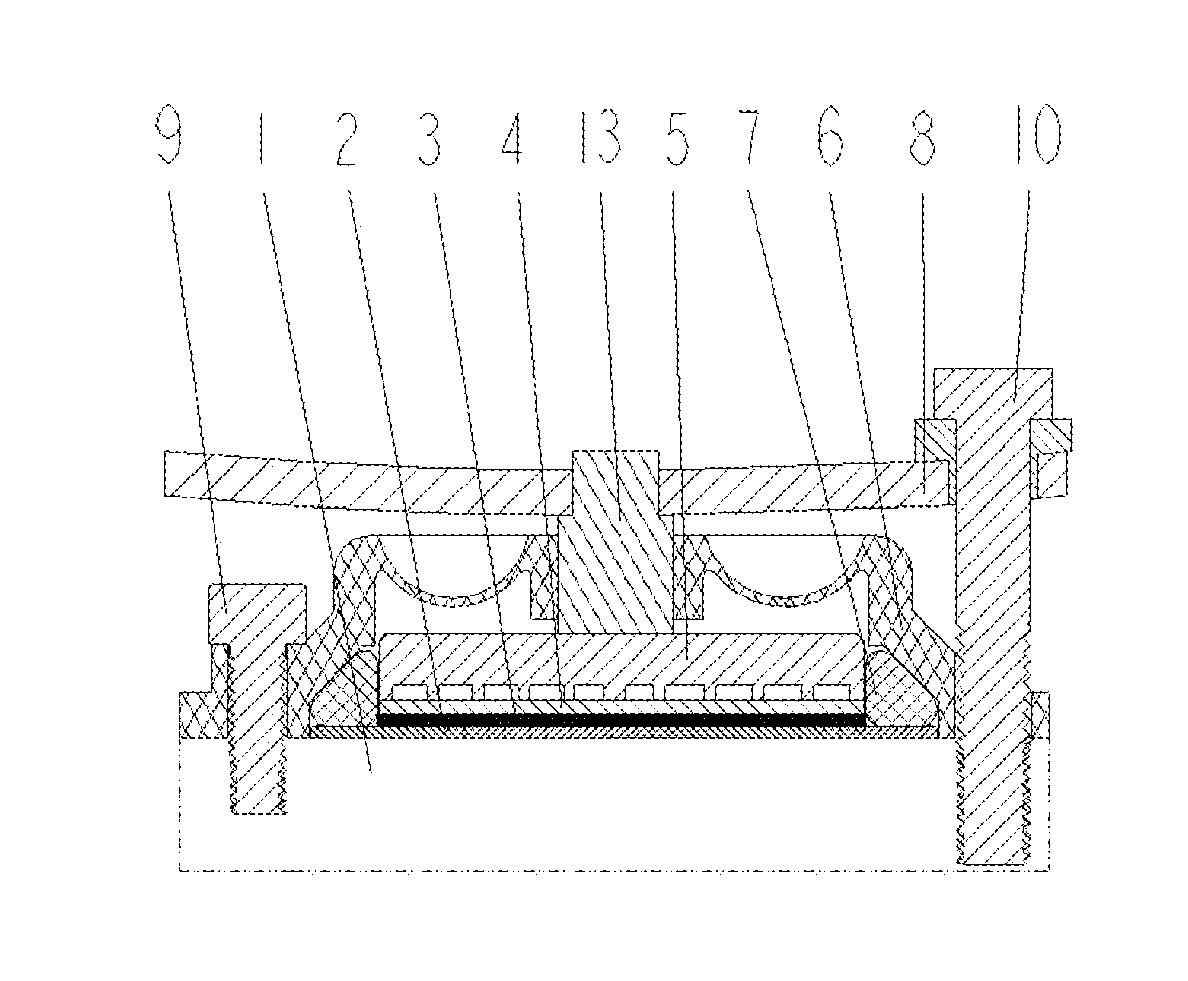

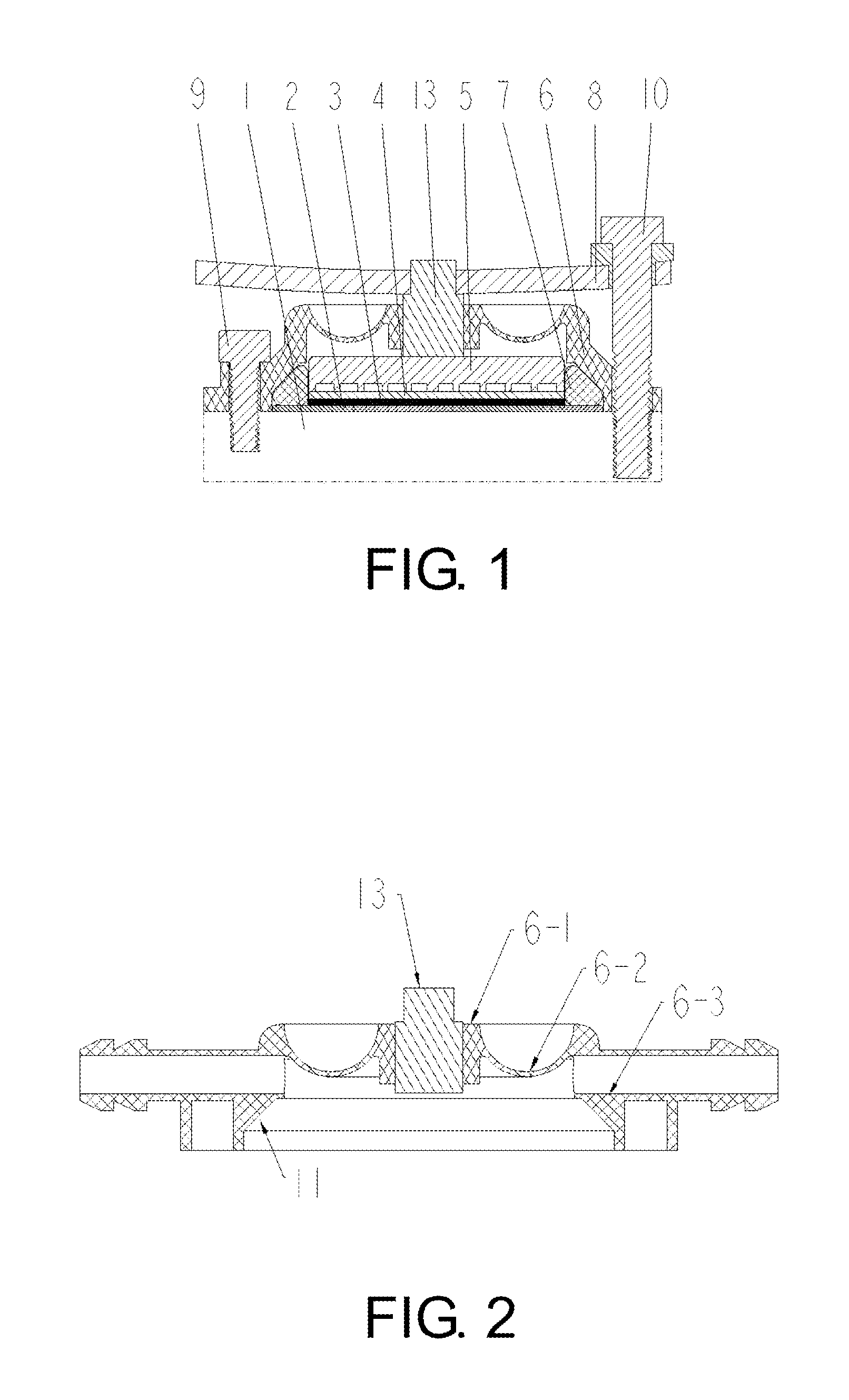

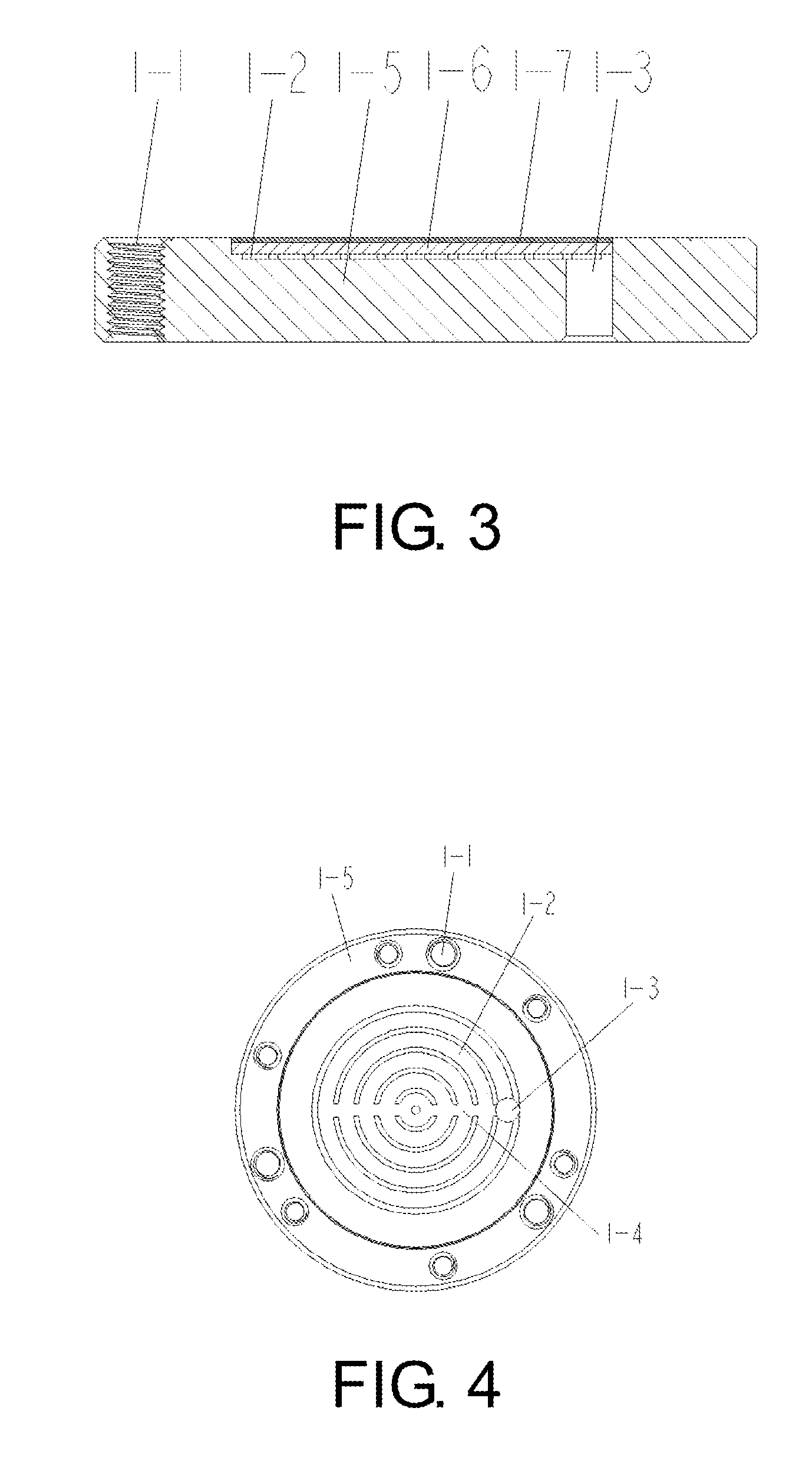

[0034]Embodiments of the present invention will now be described, by way of example only, with reference to the accompanying drawings.

[0035]As shown in FIG. 1 through FIG. 4, the electrolytic ozone generator with membrane electrode of the present invention comprises a cathode structure 1. The cathode structure 1 comprises a cathode fixed plate 1-5 which is made of a metallic titanium material. The cathode fixed plate 1-5 has a plurality of screw holes 1-1 which are evenly arranged around a circumferential portion of the cathode fixed plate 1-5. The cathode fixed plate 1-5 further has annular deflector grooves 1-2 and a transverse groove 1-4 which passes through the central portions of the annular deflector grooves 1-2. The annular deflector grooves 1-2 are interconnected through the groove 1-4 and communicate with a drainage hole 1-3. A cathode diffusion layer 1-6 is provided on the cathode fixed plate 1-5. A cathode electrocatalyst layer 1-7 is provided on the cathode diffusion lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore diameter | aaaaa | aaaaa |

| conductive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com