Method for sterilizing and disinfecting with high-temperature steam and disinfection cabinet for implementing same

A sterilization, high-temperature steam technology, applied in the field of disinfection cabinets, can solve the problem of long disinfection time, and achieve the effect of high disinfection efficiency, saving disinfection time, and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

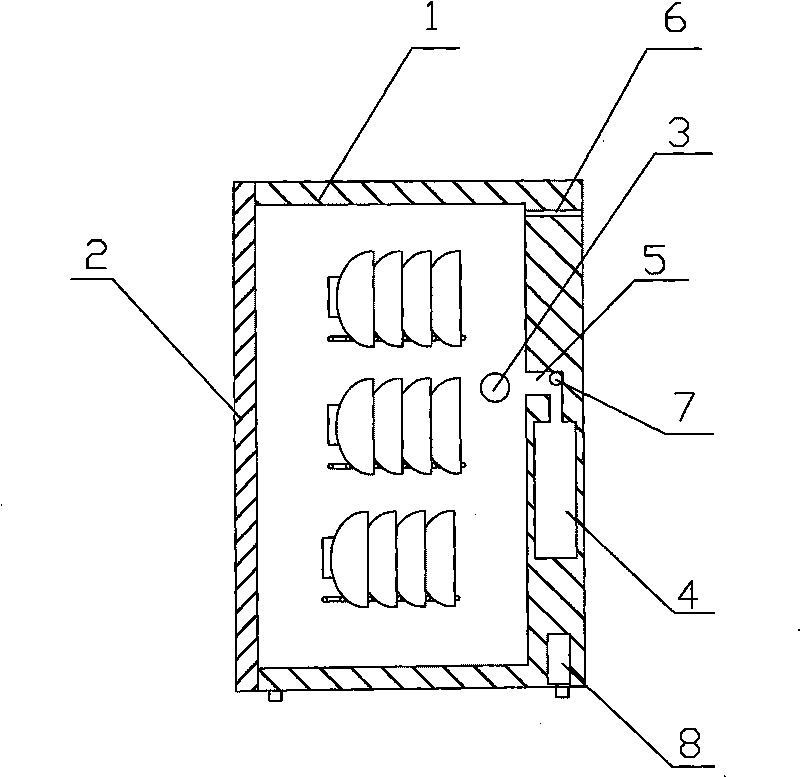

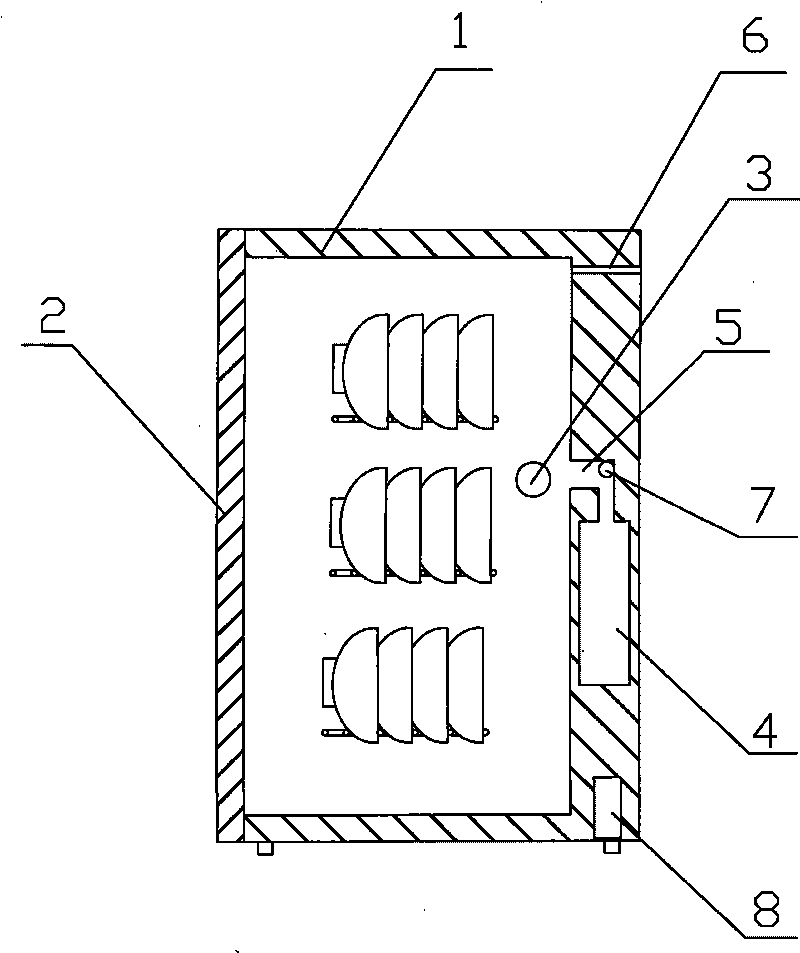

[0025] Such as figure 1 As shown, the disinfection cabinet using the high-temperature steam sterilization method includes a cabinet body 1 containing tableware to be sterilized and a cabinet door 2 installed on the cabinet body 1 to form an airtight container, and an infrared heating tube is installed in the back of the cabinet body 1 3. The steam generator 4, the exhaust hole 6 and the control circuit 8, the steam outlet 5 of the steam generator 4 leads into the cabinet 1 and faces the infrared heating tube 3, and an ultraviolet disinfection tube 7 is arranged at the steam outlet 5, and the steam The generator 4 is electrically connected with the control circuit 8 .

[0026] Steam generator 4 can use following several structural forms:

[0027] 1. It is composed of a water storage tank and an ultrasonic nebulizer. The water in the water storage tank is atomized by the ultrasonic nebulizer into steam and sprayed onto the infrared heating tube 3 through the steam outlet 5;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com