High temperature resistant dry bag-type dust remover

A bag filter, high temperature resistant technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problem of increasing the workload of repairing and replacing bags, short service life of filter bags, and increasing use and maintenance costs, etc. problems, to reduce the use and maintenance costs, reduce the workload of repair and replacement, and speed up the discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

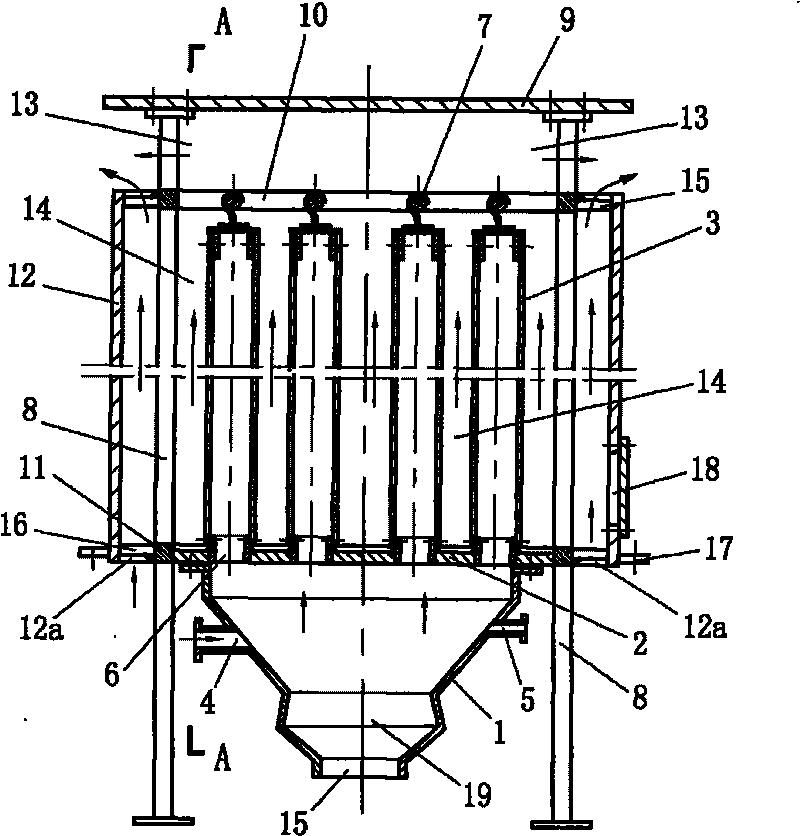

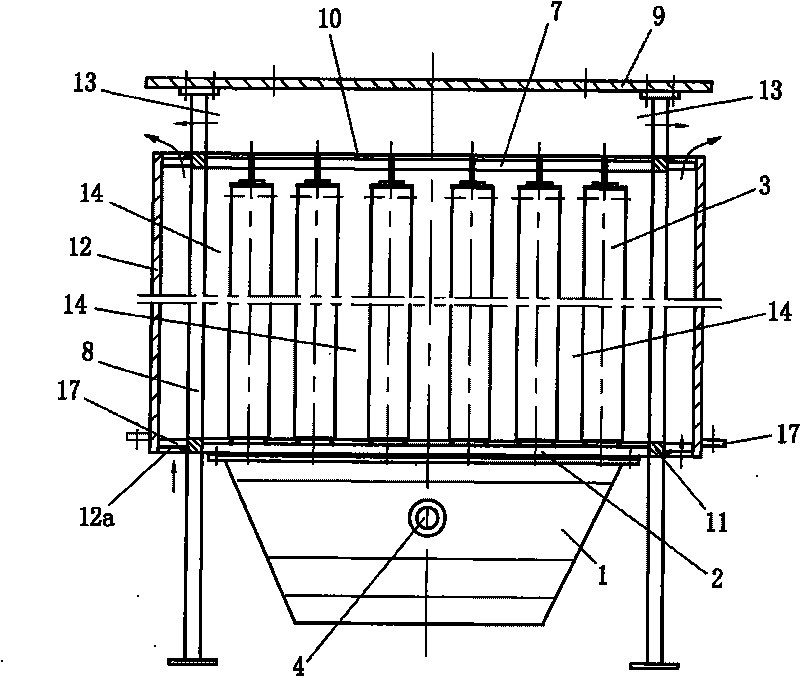

[0016] Example 1, see figure 1 , figure 2 .

[0017] The structure of embodiment 1 includes an ash hopper 1, an air distribution plate 2, several filter bags 3, an air inlet 4, and a dust-cleaning airflow hole 5, and the ash hopper 1 of this example is one; the upper part of the ash hopper 1 and the air distribution plate 2 is a sealed connection, with ash outlet 15 at the lower part; airflow holes 6 on the airflow distribution plate 2, the upper ends of the filter cloth bags 3 are respectively connected to the corresponding rods 7, and the lower ends of the filter cloth bags 3 are connected to the airflow holes 6 of the airflow distribution plate 2 The place is a sealed connection, the distribution and connection mode of the filter bag 3, in addition to the diagram and the aforementioned form, there are also a variety of variable settings; the air inlet 4 and the airflow hole 6 on the airflow distribution plate 2 It communicates with the inner cavity of the filter bag 3, t...

Embodiment 2

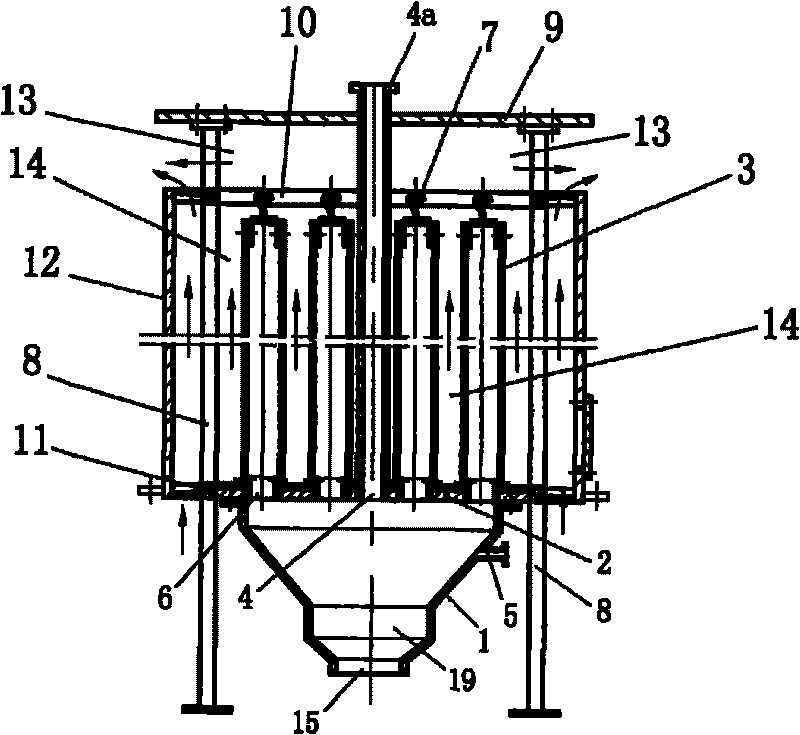

[0021] Example 2, see Figure 4 , Figure 5 .

[0022] This example is different from Embodiment 1 in that the number of filter bags 3 in the open cylinder 12 is larger than that in Embodiment 1, and two ash hoppers 1 are provided, and each ash hopper is connected to the filter bag in the cylinder 12. Part of the filter bag 3 corresponds, and each ash hopper and the corresponding filter bag 3 can be regarded as a unit; according to the number of filter bags 3, the ash hopper 1 can also be three or more to meet a larger amount When there are at least two ash hoppers 1, an air inlet channel 20 communicating with the inside of the cylinder 12 can be set between the ash hoppers, and the natural wind enters through the air inlet channel 20, which is open up and down. The inside of the cylinder 12 is to meet the cooling of the filter bag 3 in the middle, so as to effectively improve the reliability of the filter bag operation, reduce the damage to the filter bag caused by high tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com