Spraying method of deficient spraying resistance primer

A primer and leak-proof technology, which is applied to the device and coating of the surface coating liquid, which can solve the problems of missing primer and failure to find defective products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

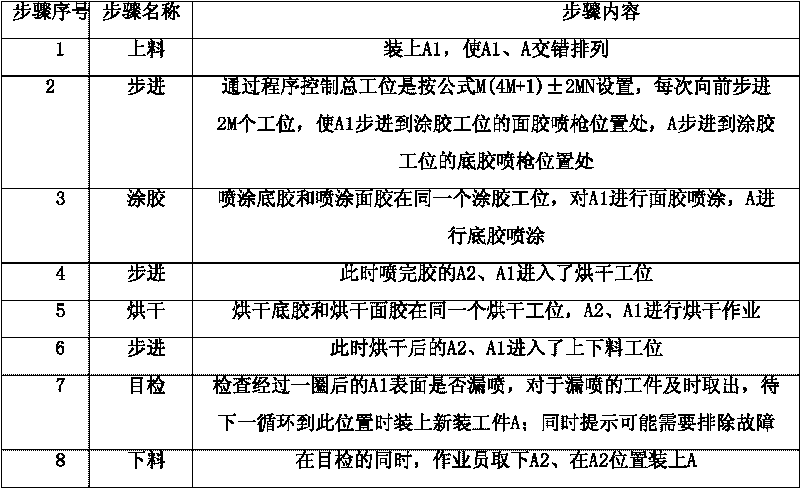

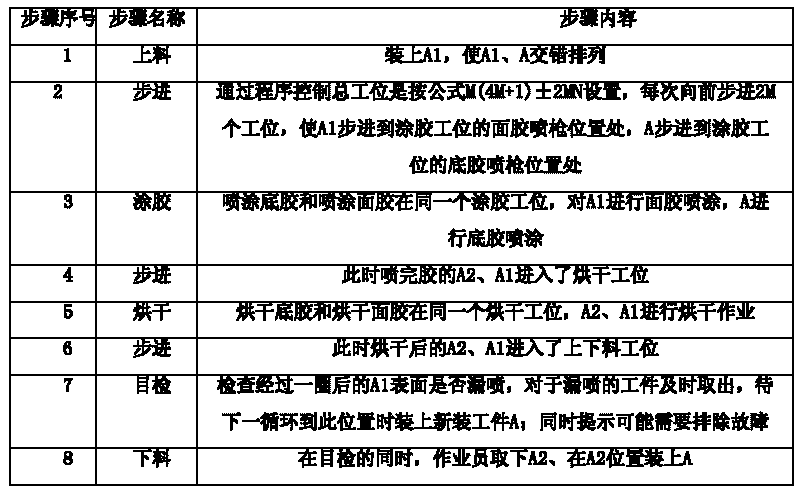

[0038] Embodiment one, such as figure 1 As shown, it is mainly for the glue spraying method of 1 bottom and 1 surface when the environmental conditions are suitable for workpieces that do not need to be preheated. Specific steps are as follows:

[0039] 1. Loading: Install the newly installed workpiece A (represented by "A" below), and ensure that there is a workpiece A1 (represented by "A1" below) sprayed with primer at the back of A at this time, so that A1 and A are staggered ;

[0040] 2. Stepping: The rotary table moves forward in one direction (for example, counterclockwise), and each time it moves forward by 2M (at this time M=1), that is, 2 stations. Since the total station is according to the formula M (4M+1)±2MN setting, in this way, the workpiece will always miss 1 station during the stepping process, at this time A1 steps to the surface glue spray gun position of the gluing station, and A steps to the gluing worker position of the primer spray gun;

[0041] 3. ...

Embodiment 2

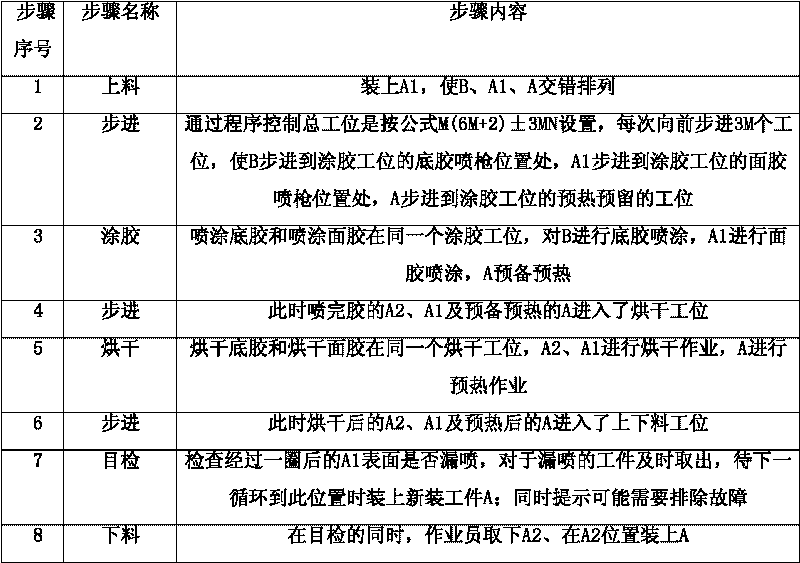

[0050] Embodiment two, such as figure 2As shown, it is mainly for the glue spraying method of 2 preheating, 2 bottom and 2 surfaces when the environmental conditions need to preheat the workpiece. Among them, the preheated (dehumidified) workpiece is represented by "B". Specific steps are as follows:

[0051] Loading: Load the workpiece A to be sprayed, so that B, A1, and A are arranged in a staggered manner;

[0052] Stepping: The rotary table moves forward in one direction (for example, counterclockwise), each time stepping forward 3M (at this time M=2), that is, 6 stations, since the total station is according to the formula M(6M +2) ±3MN setting, in this way, the workpiece will always pass through 2 stations during the stepping process. At this time, B steps to the primer spray gun position of the gluing station, and A1 steps to the gluing station. At the position of the surface glue spray gun, A steps to the preheating reserved station of the gluing station;

[0053]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com