Low-hydrogen coated electric arc welding bar

An arc welding rod, low-hydrogen type technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of insufficient and undeveloped, and achieve good low temperature toughness and crack resistance, excellent welding operational effect

Inactive Publication Date: 2010-06-09

KOBE STEEL LTD

View PDF3 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In addition, in this patent document, there is no awareness of the toughness in the low-temperature region of about -60°C, and, like JP-A-9-327793, no study has been made on the improvement of welding workability in consideration of all posture welding.

[0008] In addition, in JP-A-3-294088, although the toughness of weld metals with a tensile strength of 70 to 90 kg in the low temperature range of about -40°C was evaluated, for example, in recent years, the low temperature range of about -60°C It is still not sufficient for the strict high toughness requirements represented b

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

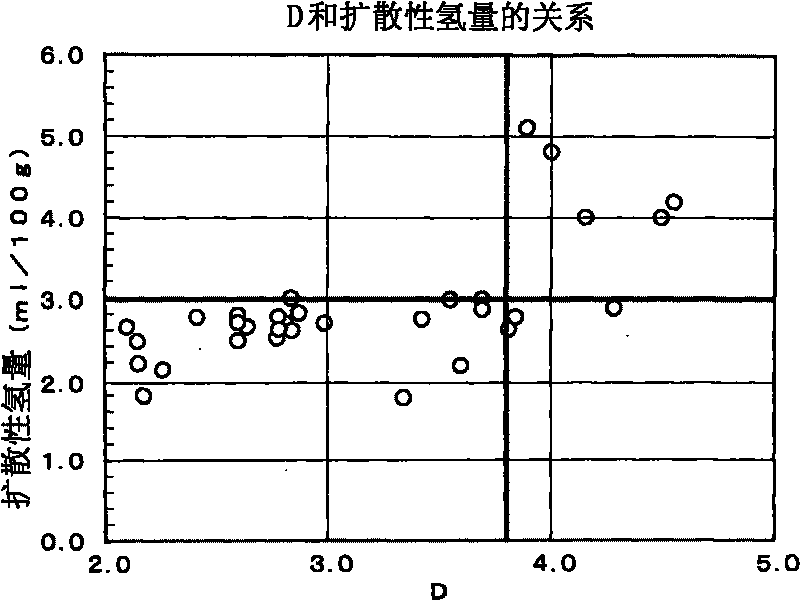

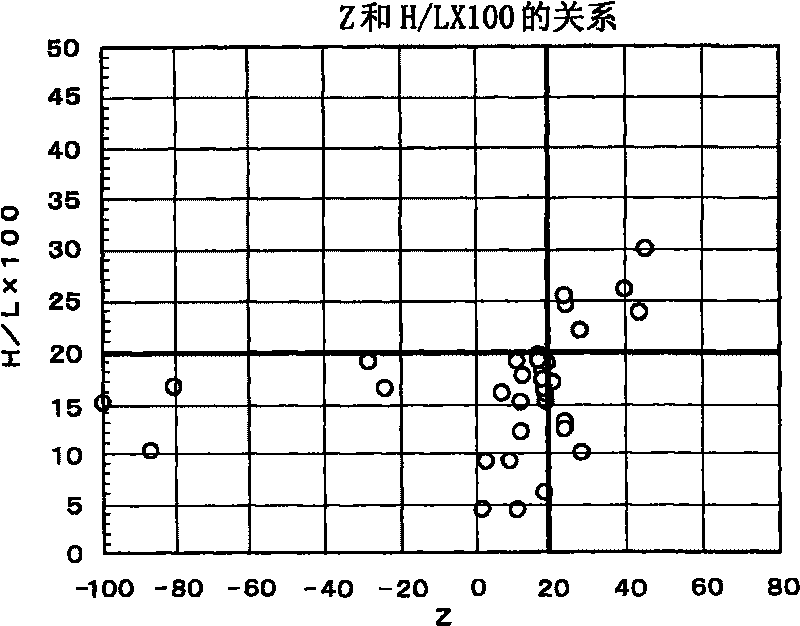

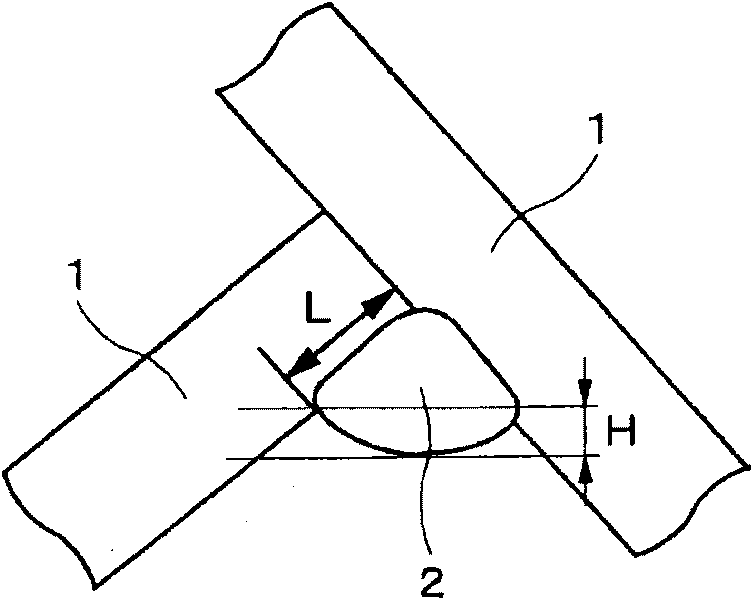

The invention provides a coated electrode which can obtain a weld metal with excellent cracking resistance and low-temperature toughness in welding of a high-tensile steel with a yield strength of 690 MPa class or more, and which ensures good weldability in all position welding. A coating ratio of a coating flux is 25 to 45 % by mass. A steel core wire contains 0.06 % by mass or less of C relative to the total mass of the steel core wire. The coating flux contains, relative to the total mass of the coating flux, 14.7 to 22.4 % by mass of metal carbonate (in terms of CO2 ), 13.1 to 24.8 % by mass of CaF2, 0 to 8 % by mass of TiO2, 0 to 8 % by mass of ZrO2, 1.1 to 3.0 % by mass of SiO2, 0 to 0.8 % by mass of Al2O3, 0.01 to 0.05 % by mass of C, 2.5 to 6.0 % by mass of Si, 2.2 to 8.0 % by mass of Mn, 1.8 to 7.0 % by mass of Ni, and 0.2 to 3.7 % by mass of Cr + Mo, and the balance including Fe, alkali metal fluoride, alkali metal oxide, alkali-earth metal fluoride (except for CaF2), alkali-earth metal oxide, B, Al, and Mg, and inevitable impurities (P, S, V, Nb, Sn). The following formula is satisfied: D=8.42-0.18CO2+0.05CaF2+0.50TiO 2-1.36SiO2-4.36Al2O3+0.71ZrO2<=3.8.

Description

technical field [0001] The present invention relates to a low-hydrogen type covered arc electrode effective for welding high-tensile steel with a yield strength of 690 MPa or higher, and particularly relates to a welding operation in all-posture welding capable of obtaining a welded portion excellent in crack resistance and low-temperature toughness Low-hydrogen covered arc electrode for high-tensile steel with good performance. Background technique [0002] With the increase in size of steel structures in recent years, in order to achieve weight reduction of steel structures, the application of high-tensile steel to steel structures is advancing. In particular, in the fields of marine structures and pressure vessels, good low-temperature toughness is required, and the demand for welding materials satisfying this is increasing. So far, welding consumables with relatively good low-temperature toughness and crack resistance have been used in covered arc welding and submerged ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K35/365

CPCB23K35/0266B23K35/226B23K35/3053B23K35/365B23K35/22B23K35/3602B23K35/0255

Inventor 日高武史

Owner KOBE STEEL LTD

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com