Nailing machine structure

A nailing machine and nailing cartridge technology, applied in the field of nailing machines, can solve the problems of user application limitation, danger, loss, etc., and achieve the effects of improving convenience, safety, and convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

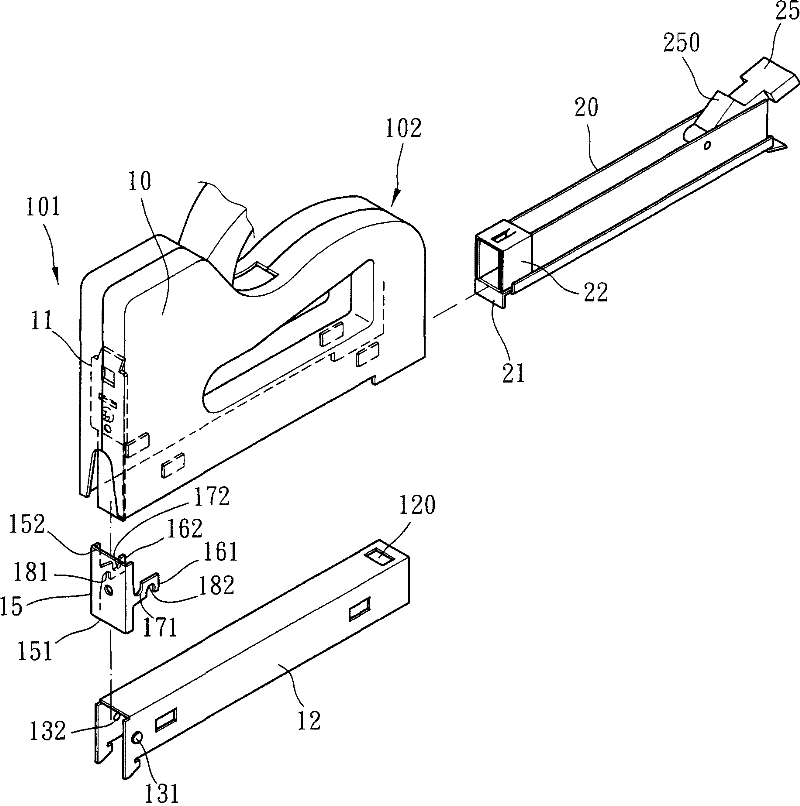

[0077] For the detailed composition of the nailing machine of the present invention, please refer to Figure 4 to Figure 8 As shown, the nailing machine generally includes a body 30, a nail magazine 40 and a dialing member 50, wherein the nail magazine 40 can be slidably embedded in the bottom edge of the body 30, and the dialing member 50 on the body 30 can change the nail magazine 40 positioning position;

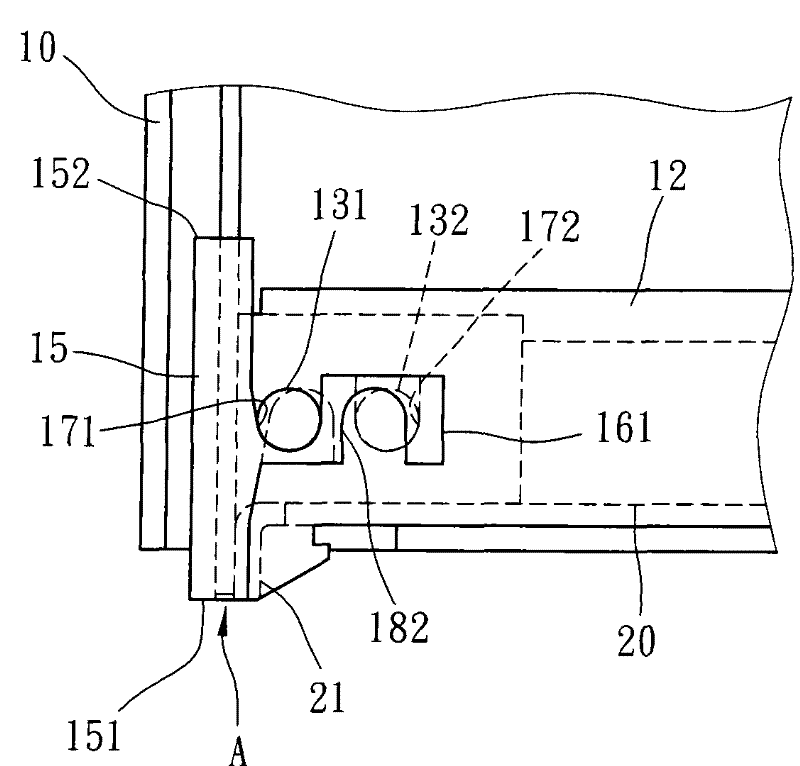

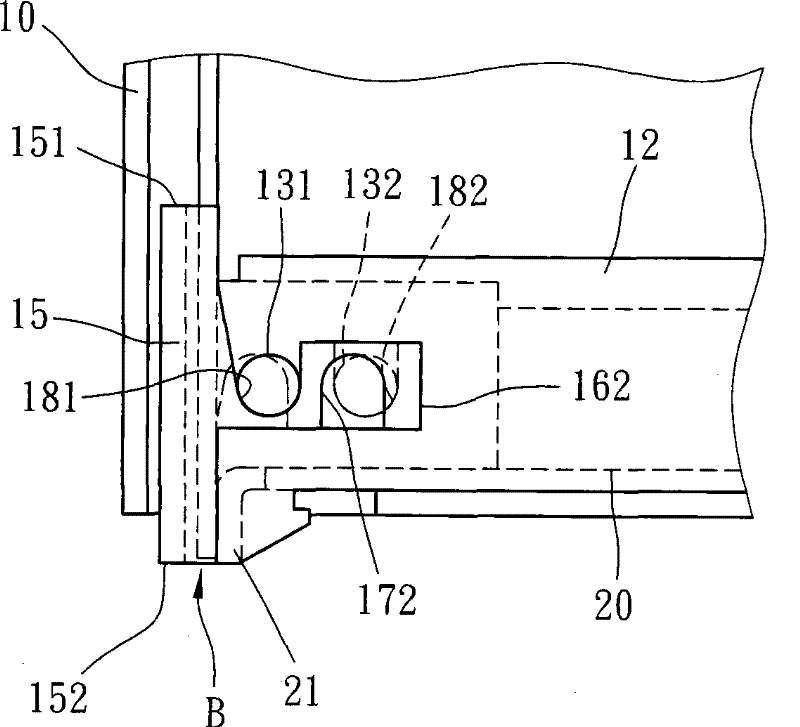

[0078] The aforementioned machine body 30 is made up of two opposite shells, and the two ends of the machine body 30 respectively have a nailing moving part 301 and a nail box entry and exit part 302, wherein the nailing moving part 301 has a downward powerful firing The nail plate, related driving components, etc., and the nail box inlet and outlet part 302 can be used for sliding in and selectively positioning the aforementioned nail box 40 for accommodating the nail body. Remove the horizontal frame 31 below the mouth, and the body 30 is provided with a front guide pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com