Positioning thermoprinting method and positioning thermoprinting label

A label and printing plate technology, applied in the positioning hot stamping method and the field of labels, can solve single problems, achieve the effects of low cost, meet individual needs, and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

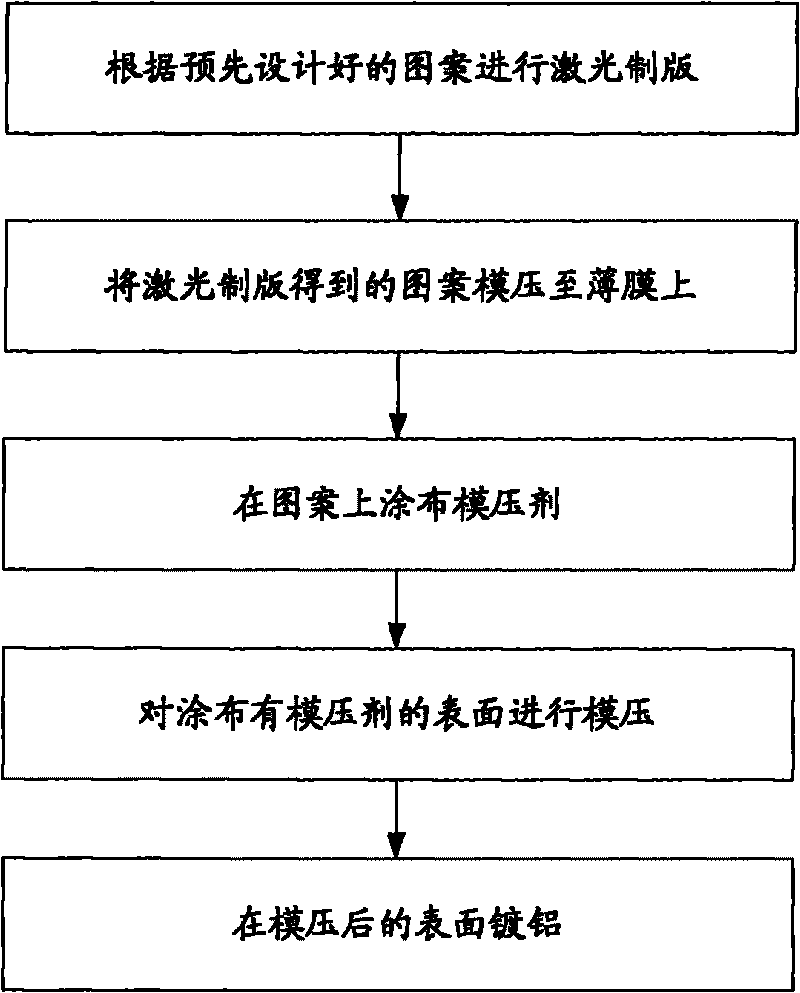

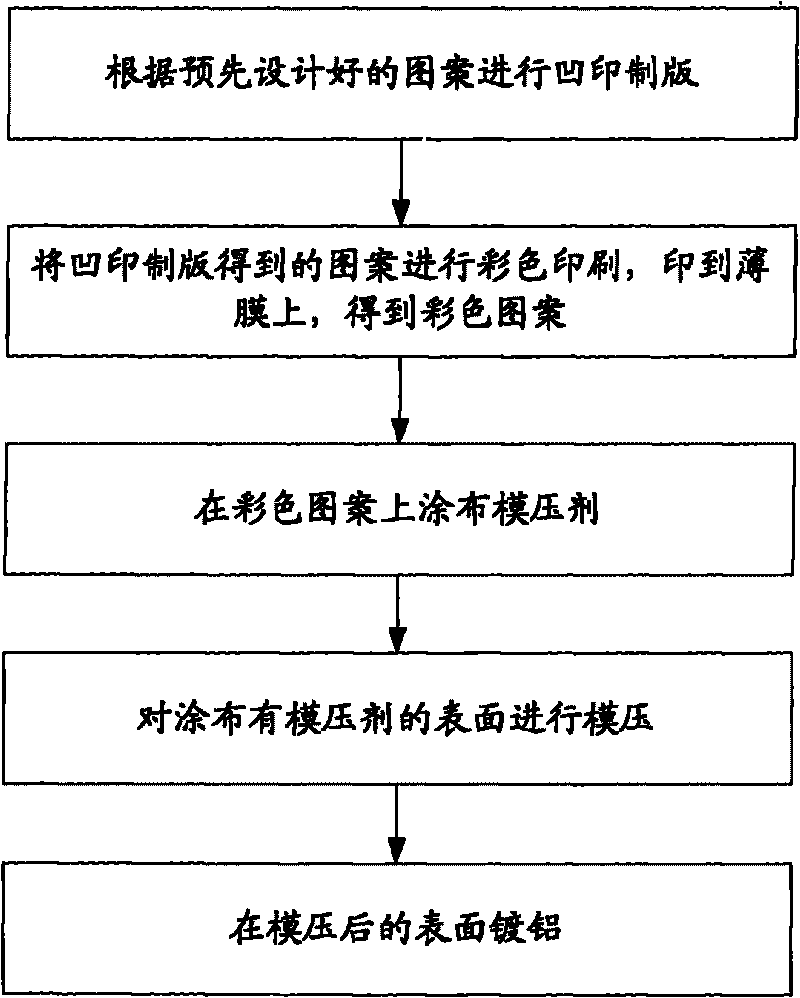

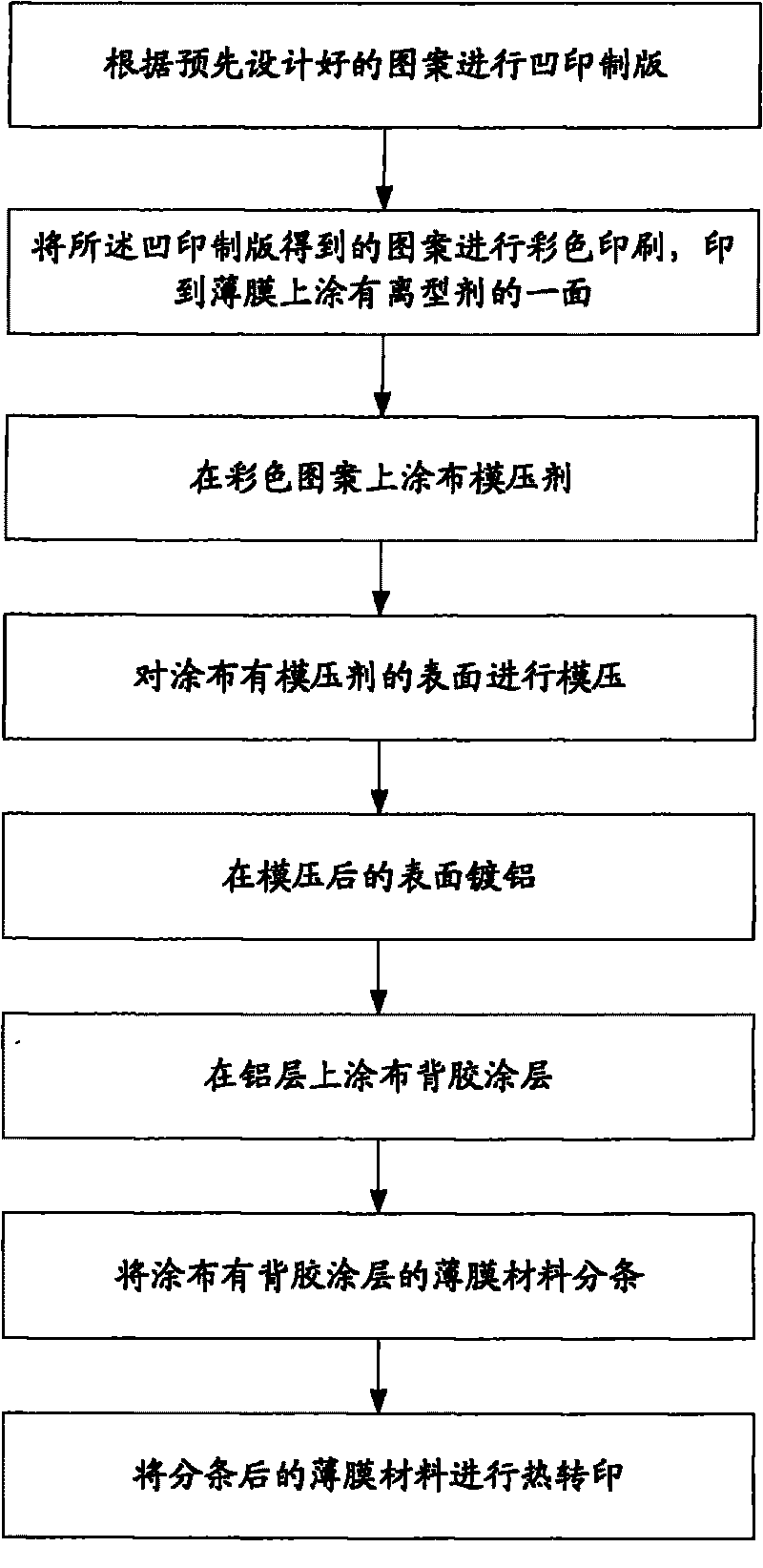

[0045] The invention provides a new method of color holographic positioning hot stamping, which uses gravure plate making to replace the laser plate making process in the existing positioning hot stamping method, so that colorful patterns can be printed, so that the pattern of positioning hot stamping Get colorful effects while having a holographic effect.

[0046] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0047] refer to figure 2 , figure 2 It is a flow chart of the positioning hot stamping method of the present invention. figure 2 Include the following steps:

[0048] Gravure plate making according to the pre-designed pattern;

[0049] The method of designing the pattern in this step is the same as the existing design method of positioning hot stamping pattern, the difference is that the existing laser plate making method is replaced by gravure plate making. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com