Automatic focal power packing machine for lens

A packaging machine and lens technology, which is applied in the field of lens automatic focus packaging machines, can solve the problems of high labor intensity, inaccurate measurement, and wrong classification of workers, so as to reduce the workload of workers and product measurement errors, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

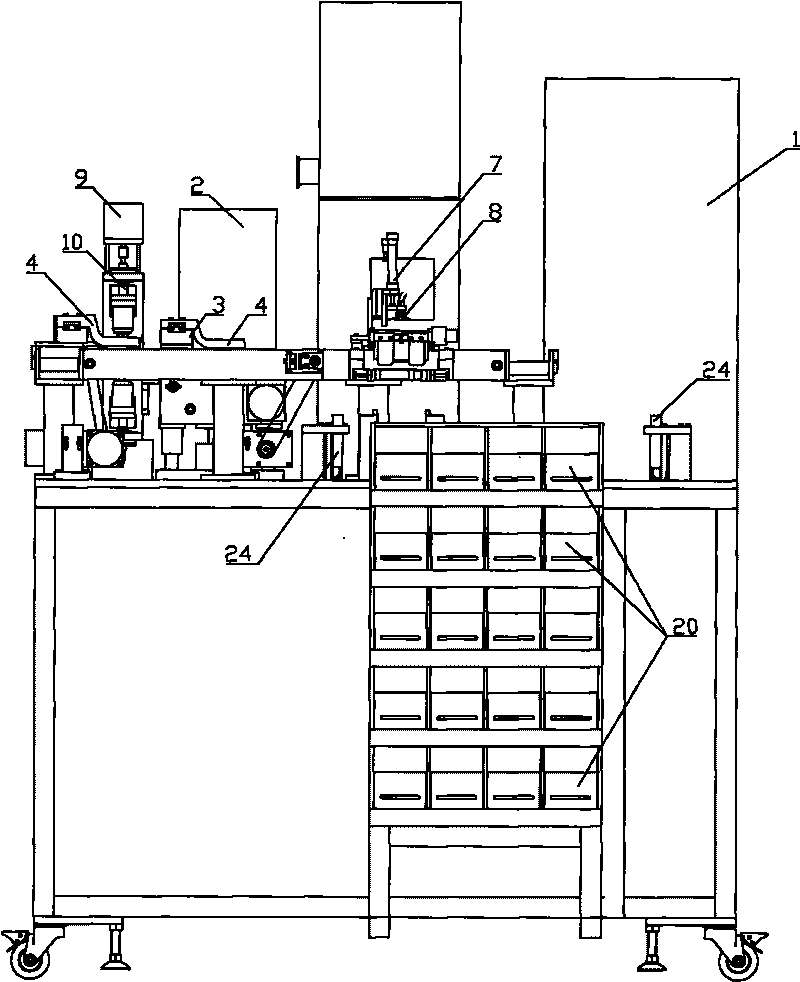

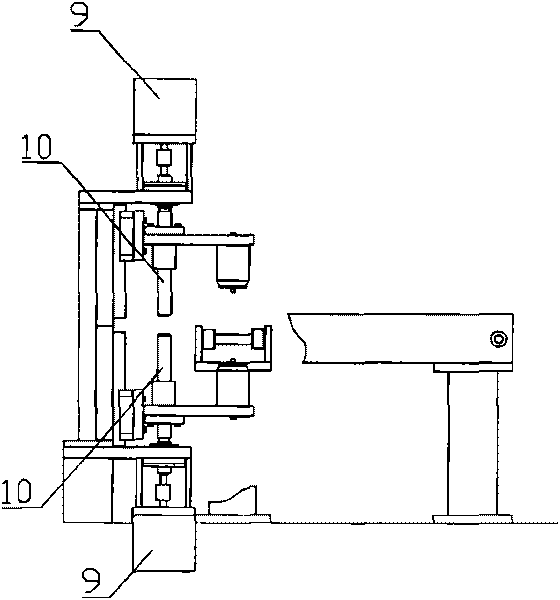

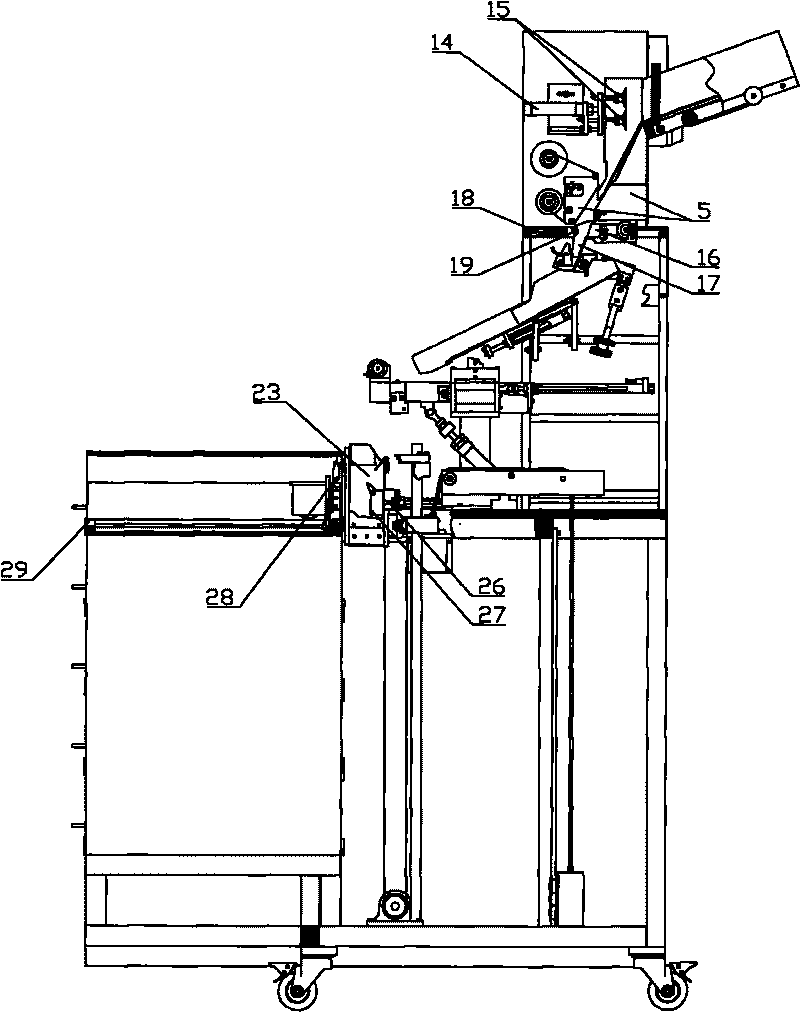

[0021] figure 1 is the front view of the present invention; figure 2 It is a schematic diagram of the structure of the lens thickness detection device; image 3 Schematic diagram of the printing, packaging, and classification parts of the present invention; Figure 4 It is a top view of the lens conveying line of the present invention; Figure 5 It is a structural schematic diagram of the sorting device of the present invention, as shown in the figure: the lens automatic focus packaging machine of this embodiment includes a lens conveying line, a paper bag conveying line, a lens bagging device and a control system 1; A degree detection device, the power detection device includes a lens meter 2 and a lens positioning clip that can reciprocate longitudinally and laterally along the lens meter 2, and the lens positioning clip includes two positioning clip cylinders 3 and two oppositely arranged and The clip body 4 that can be driven by the positioning clip cylinder 3 to reali...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap