Rectification system for separating mixture rich in aromatic hydrocarbon

A rectification system and mixture technology, applied in hydrocarbon distillation, petroleum industry, etc., can solve the problems of large number of equipment, high operating cost, large investment, etc., and achieve the effect of less equipment, low operating cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

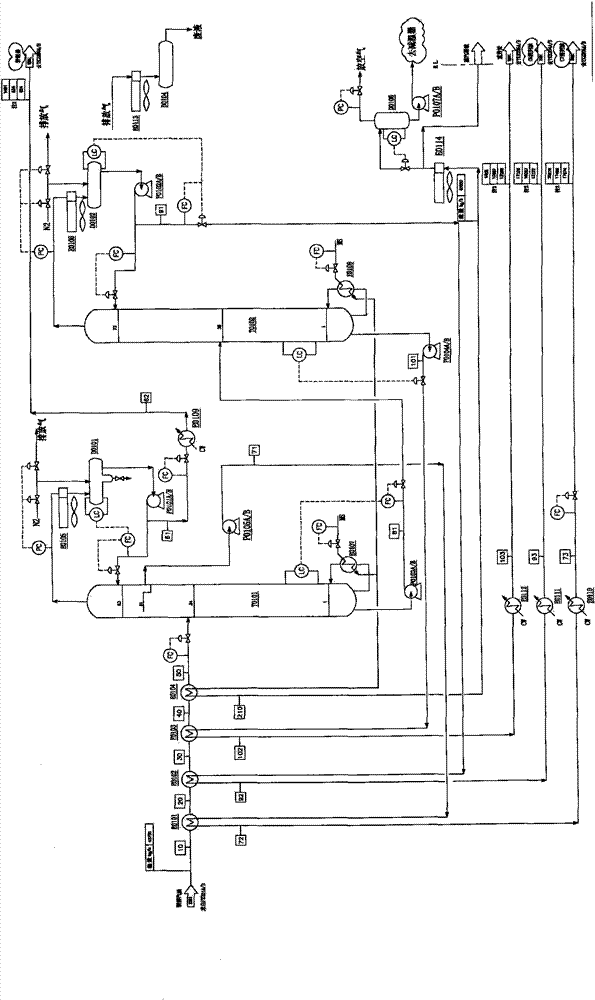

[0049] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

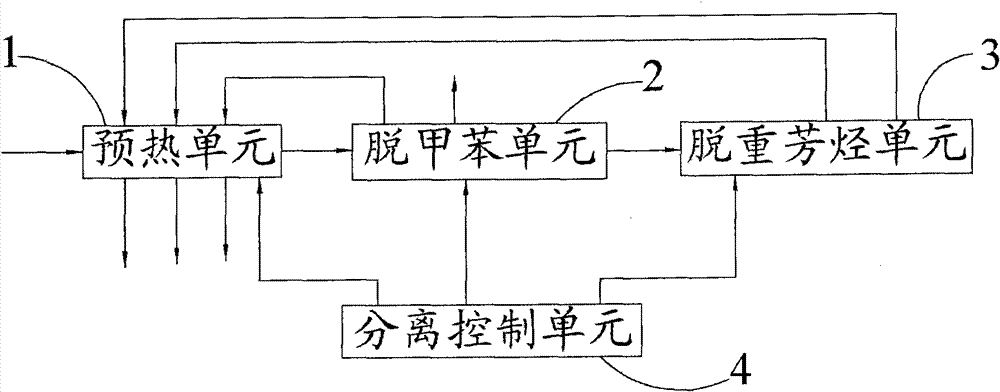

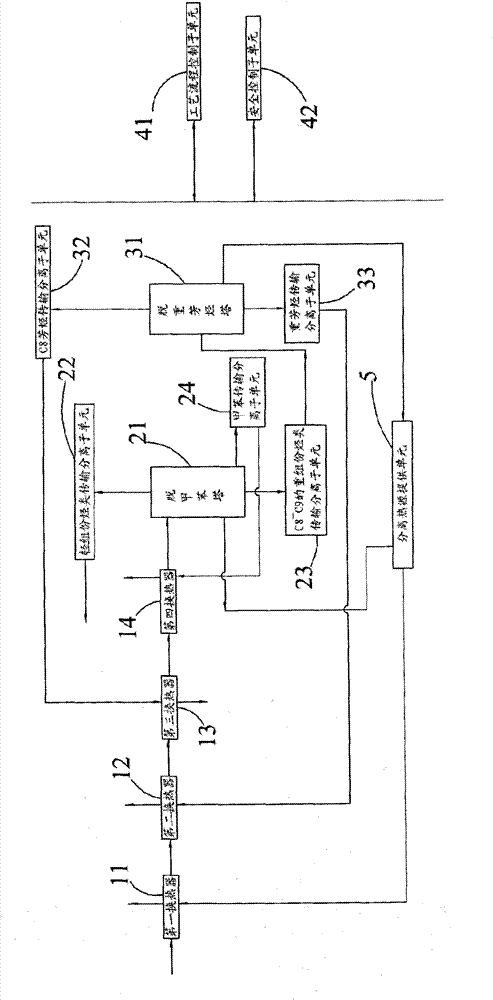

[0050] see figure 1 As shown, it is a functional block diagram of the rectification system for separating rich aromatics mixtures of the present invention; the described rectification system for separating rich aromatics mixtures includes: a preheating unit 1, in order to realize the preheating of hydrocracked gasoline hot;

[0051] A detoluene unit 2, which obtains the hydrocracked gasoline preheated by the preheating unit 1, and obtains light component hydrocarbon products, toluene products and C8~C9 heavy component hydrocarbon products through split flow, wherein the toluene The split flow of the product still needs to be heat-treated by the preheating unit 1, and can be separated after condensation treatment;

[0052] A heavy aromatics removal unit 3, which obtains the C8-C9 heavy component hydrocarb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com