Catchcord opening apparatus of loom

A technology of shedding device and warp thread, which is applied in the field of warp thread shedding device at the weft catching edge, can solve problems such as weft yarn retraction, and achieve the effect of avoiding fabric quality damage and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

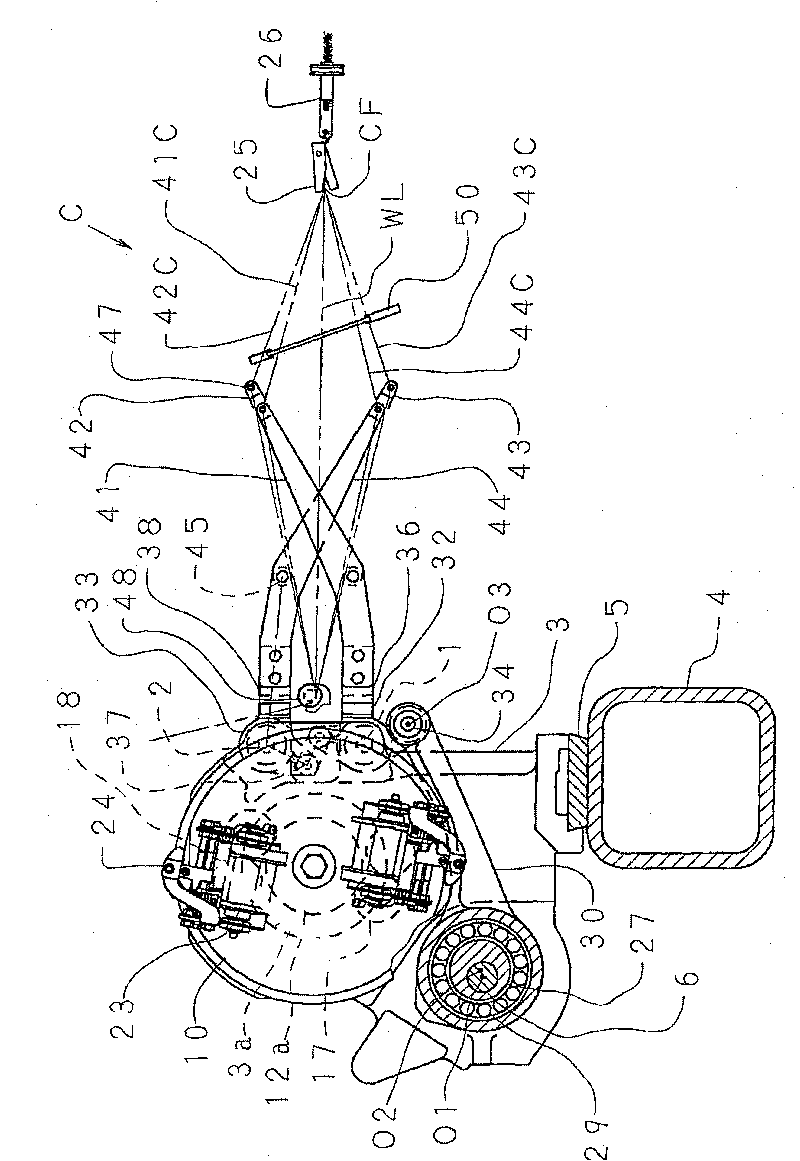

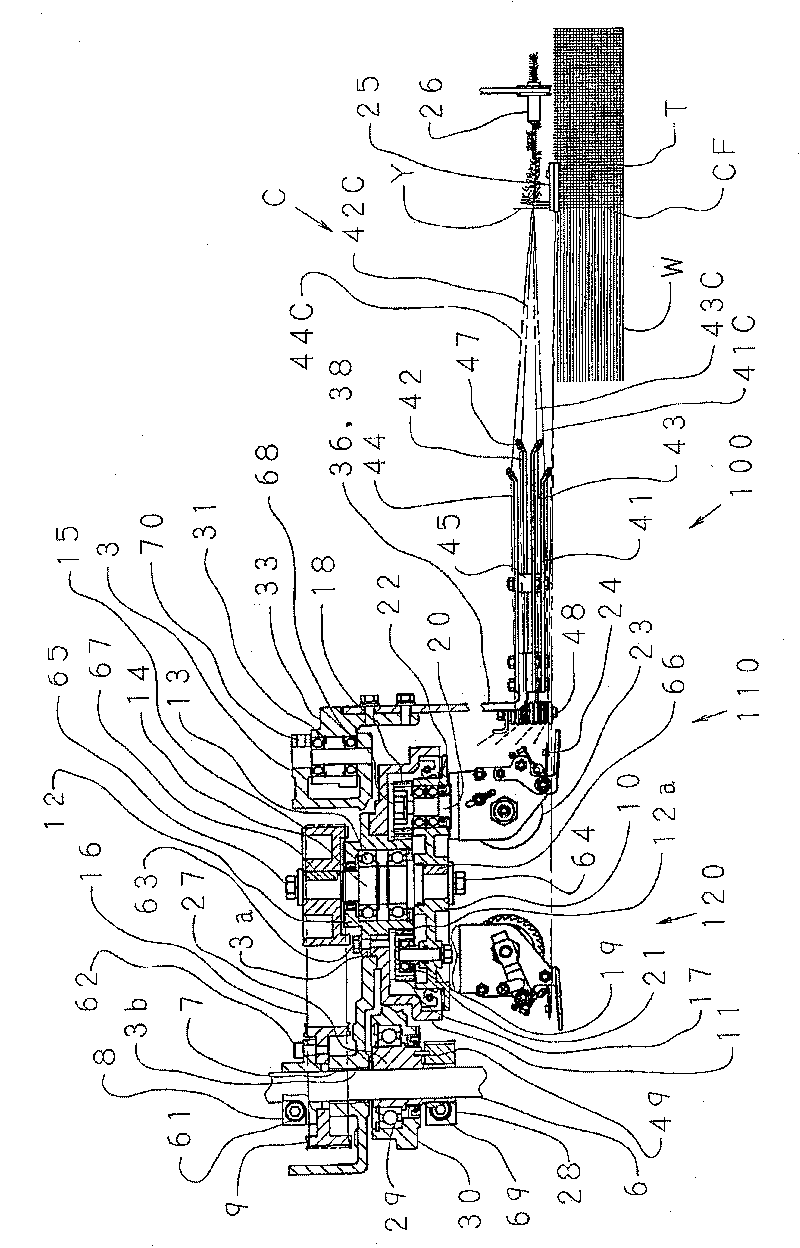

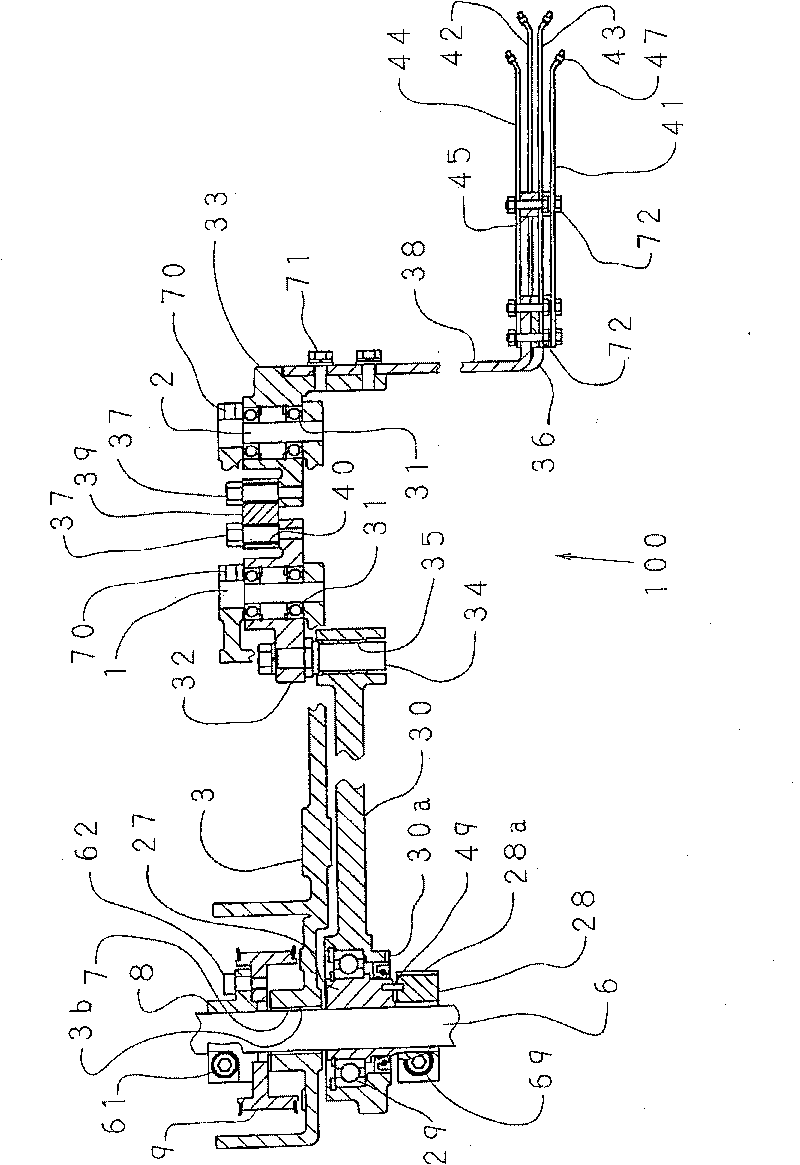

[0046] Hereinafter, a first embodiment of the present invention will be described with reference to the drawings. The warp thread opening device 100 of the weft catching edge of the first embodiment is used as a fluid jet loom for a water jet loom or an air jet loom, and the planetary edge selvedge device installed on the side opposite to the weft insertion of the loom 110 are arranged contiguously.

[0047] figure 1 It is a front view showing the warp opening device 100 of the weft catching side seen from the center of the loom along the fabric width direction on the side opposite to the weft insertion (reverse weft entry side). In addition to the warp opening device 100 of the weft catching side, there are also Shown are the planetary edge selvedge device 110, the reed 50, the weft yarn cutting device 25 for cutting the weft yarn Y held by the warp thread C of the caught weft edge, and the false twist spindle device 26 for false twisting the warp thread C of the caught weft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com