Damper gear in lace machine

A baffle device and lace machine technology, applied in the direction of braided fabrics, textiles and papermaking, etc., can solve the problems of failing to meet the design requirements, difficult processing, large deformation, etc., to reduce processing difficulty, improve processing accuracy, reduce The effect of small processing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

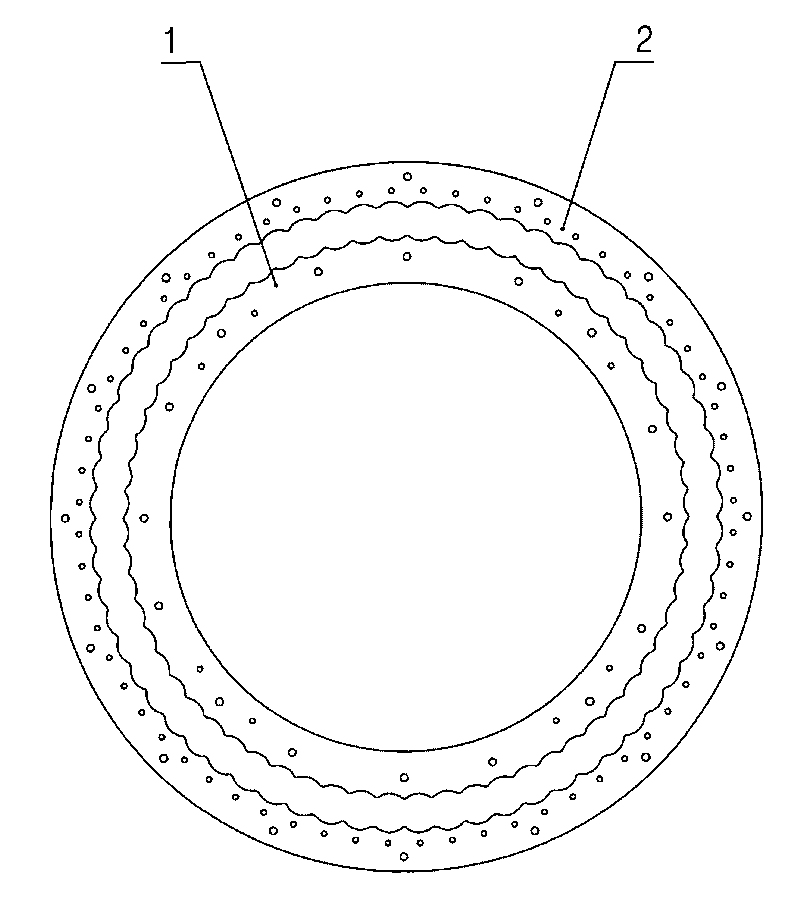

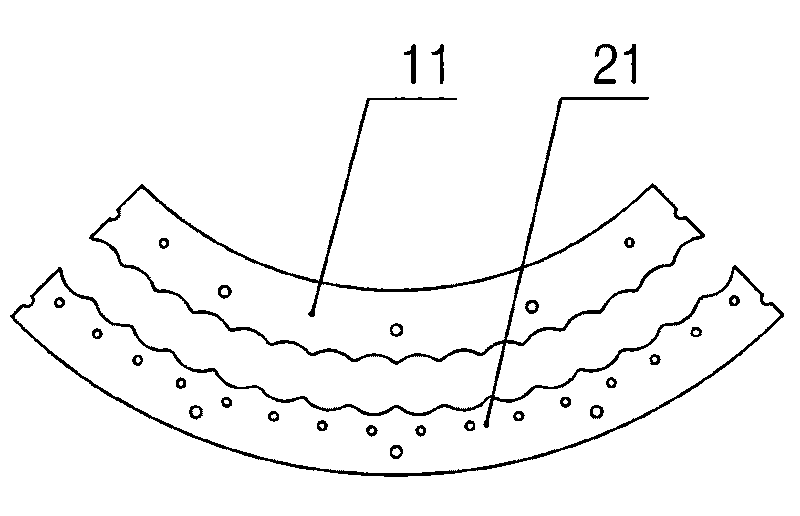

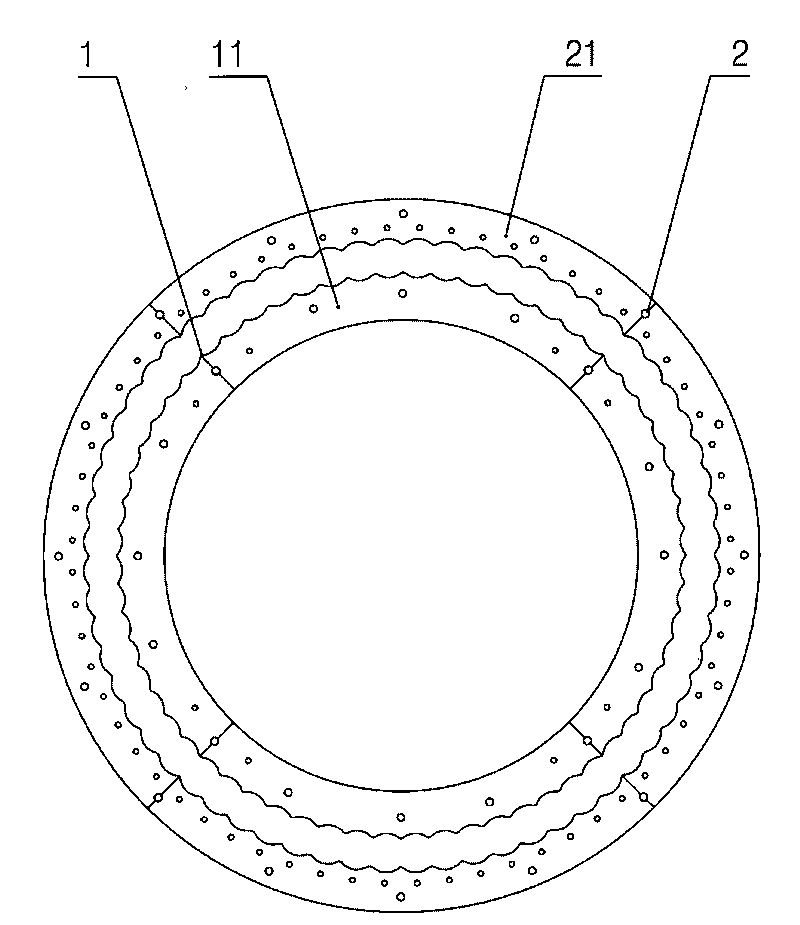

[0012] Such as figure 2 , image 3 As shown, the baffle device in the lace machine of the present invention includes: annular inner and outer baffles 1 and 2, and the inner and outer baffles 1 and 2 are assembled structures, that is, the inner The baffle plate 1 is assembled by four inner arc-shaped plates 11, and the outer baffle plate 2 is assembled by four outer arc-shaped plates 21.

[0013] According to the size of the lace machine, the present invention splits the inner and outer baffles into a plurality of corresponding inner arc-shaped plates 11 and outer arc-shaped plates 21, so that the original processing of the whole inner and outer baffles , has become the processing of multiple arc-shaped plates 11 and 21, the deformation of the inner and outer arc-shaped plates 11 and 21 can be controlled within the specified range, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com