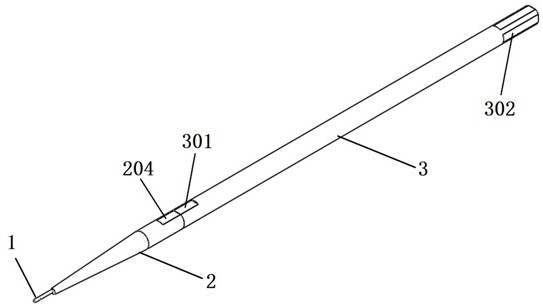

An Eccentric Cylindrical Single Hole Pneumatic Probe with High Spatial Measurement Accuracy

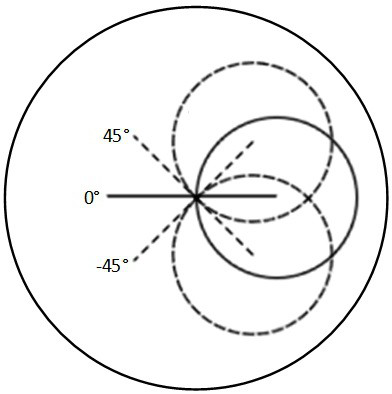

A technology with high measurement accuracy and high space, which can be used in aerodynamic tests, measurement devices, and machine/structural component testing. The effect of processing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

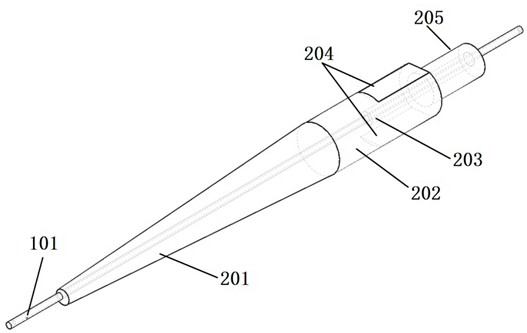

Embodiment 1

[0038] The outer diameter of the capillary 1 of this embodiment is 1mm, the inner diameter is 0.6mm, and a pressure measuring hole 101 with a diameter of 0.1mm is opened at a position 3mm away from the sealing place at the front end of the capillary 1, and the length of the front end of the capillary 1 protruding from the front section 201 of the probe head is The tail of the capillary 1 protrudes from the rear section 205 of the probe head to a length of 10 mm, and the tail of the capillary 1 is connected to the pressure measuring hose. The diameter of the front section of the stepped hole 203 is 1mm, and the diameter of the rear section of the stepped hole 203 is 2mm. In the rear section of the stepped hole 203, the capillary 1 and the probe head 2 are adhered and fixed by an adhesive. The outer diameters of the middle section 202 of the probe head and the pole 3 are both 8 mm. The middle section 202 of the probe head is provided with upper and lower two parallel positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com