Patterned color conversion array Micro LED as well as preparation method and application thereof

A color conversion and patterning technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of uneven coating of phosphor powder, poor material stability, affecting display quality, etc., and achieve high mechanical strength and high performance. Good stability and color uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for preparing a patterned color conversion array micro LED, comprising the following steps:

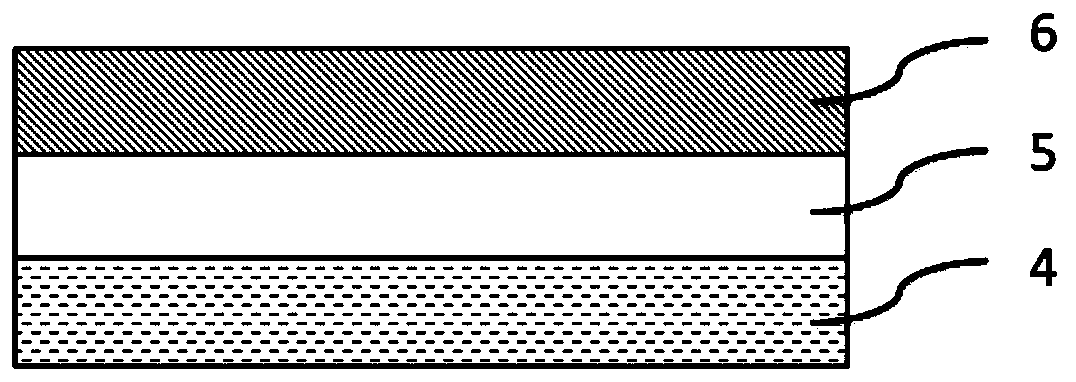

[0053] Step 1: Align the red fluorescent crystal 6 and the green fluorescent crystal 4 to be processed by bonding the intermediate layer 5 to carry out three-layer bonding. The cross-sectional view of the sample after bonding is shown in figure 2 , the bonded sample includes a green fluorescent crystal 4 , an adhesive intermediate layer 5 and a red fluorescent crystal 6 sequentially arranged from bottom to top. Among them, the adhesive middle layer is 3M TM Optically clear adhesive 8146-x;

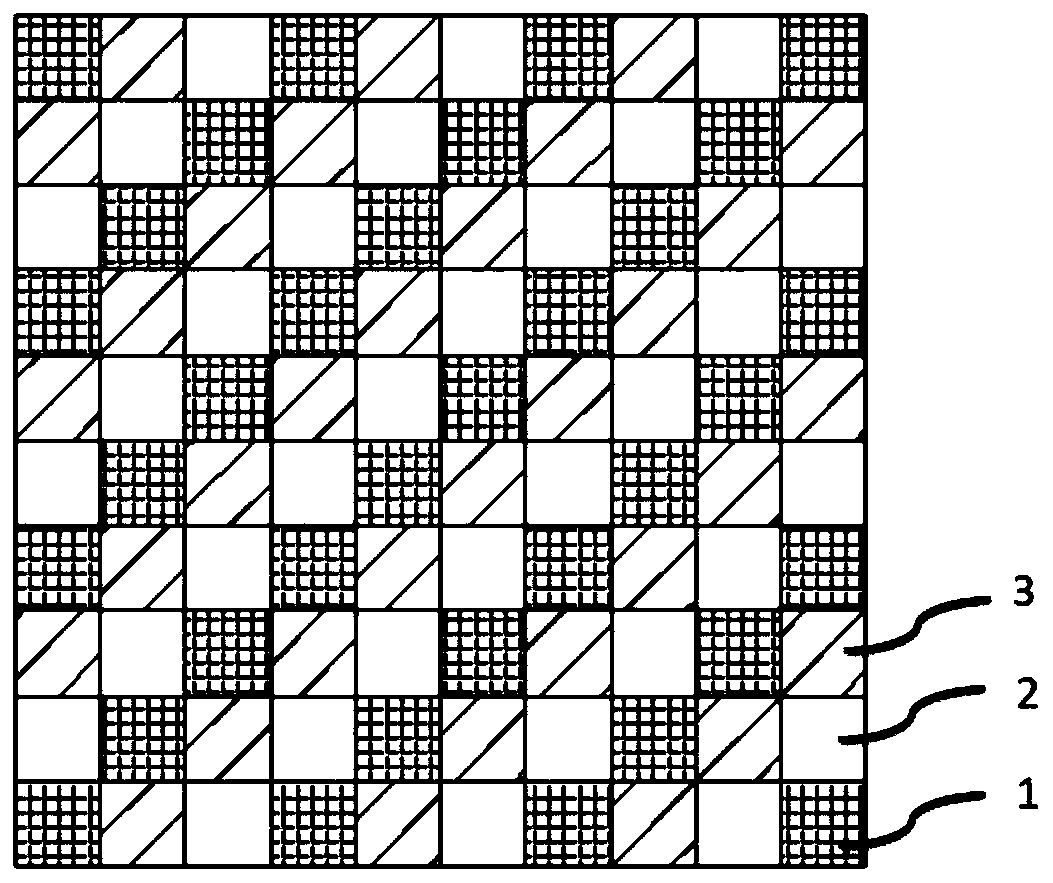

[0054] Step 2: Cut off the redundant part of the periodic pattern of the red fluorescent crystal 6 by laser processing and cutting to form a number of red fluorescent crystal grains 3 , and make a period of the red fluorescent fluorescent crystal grain 3 on the side of the adhesive intermediate layer 5 sexual array.

[0055] In step 2, the patterns obtained by laser processing ...

Embodiment 2

[0059] The specific implementation steps of a method for preparing a patterned color conversion array micro LED are as follows:

[0060] Step 1: Bond the red fluorescent crystal 6 with a thickness of 2 mm and the green fluorescent crystal 4 with a thickness of 2 mm to be processed. For the cross-sectional view of the sample formed after bonding, see Figure 6 .

[0061] Step 2: cut off the redundant part 8 of the periodic pattern of the red fluorescent crystal 6 by laser processing and cutting to form a number of red fluorescent crystal grains 3 and a number of green fluorescent crystal grains 2 to obtain a periodic array.

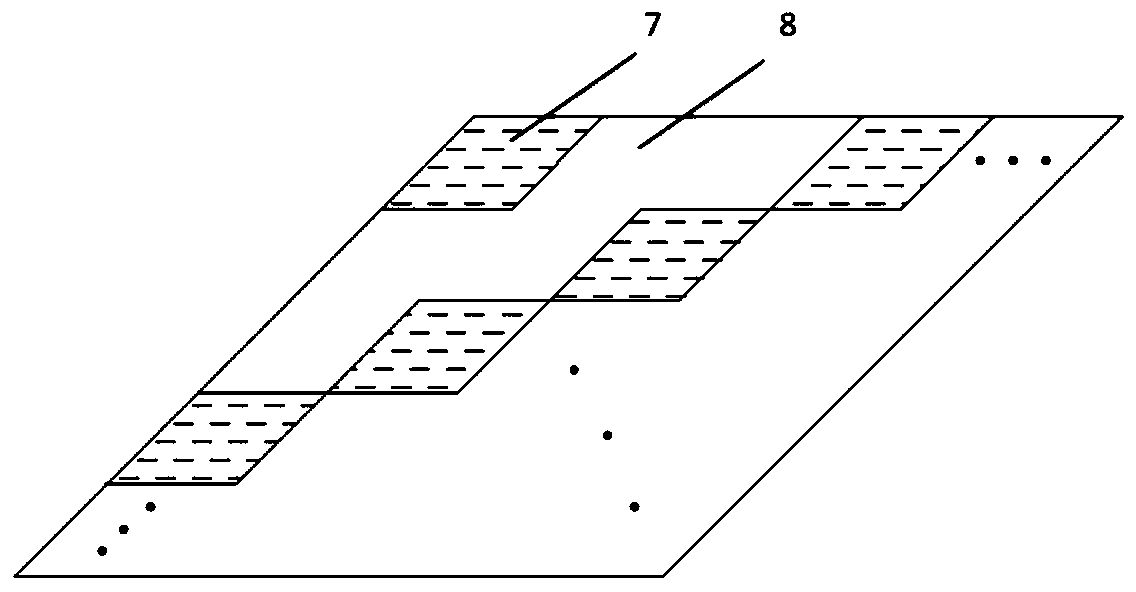

[0062] Wherein, cutting the red fluorescent crystal 6 keeps the frame. The red fluorescent crystal grains 3 are connected to each other, several green fluorescent crystal grains 2 and the first frame 91, and the edges of the red fluorescent crystal grains 3 are directly connected to the reserved frame, as Figure 7 shown.

[0063] Step 3: Turn over the ...

Embodiment example 3

[0066] The specific implementation steps of a method for preparing a patterned color conversion array micro LED are as follows:

[0067] Step 1: Process the red fluorescent crystal 6 and the green fluorescent crystal 4 by laser cutting to realize the patterning of the fluorescent crystal material, and respectively obtain the green fluorescent crystal grains 2 and the red fluorescent crystal grains 3 arranged in an array. After processing, the fluorescent crystal has a reserved frame, and the width of the reserved frame of the red fluorescent crystal is the same as that of the green fluorescent crystal. The patterns are connected to each other, and the edges are directly connected to the reserved frame, such as Figure 7 shown.

[0068] Step 2: Align the reserved frames of the patterned red fluorescent crystals and green fluorescent crystals up and down, such as Figure 8 shown.

[0069] Step 3: Double-layer bonding or triple-layer bonding (transparent bonding middle layer 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com