Clothes dryer condenser core

A technology for condensers and clothes dryers, which can be used in household clothes dryers, washing devices, textiles, and papermaking, and can solve problems such as difficult processing, low heat dissipation, and poor strength of the occlusal plate frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

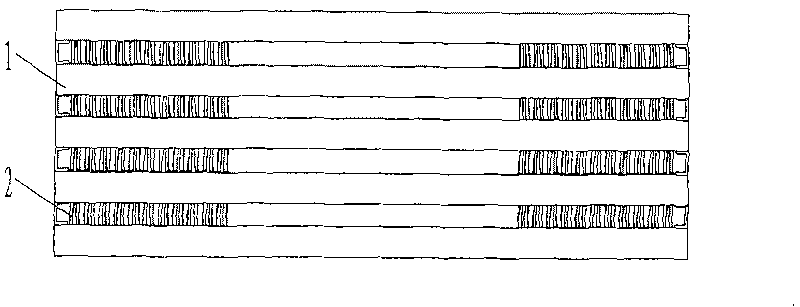

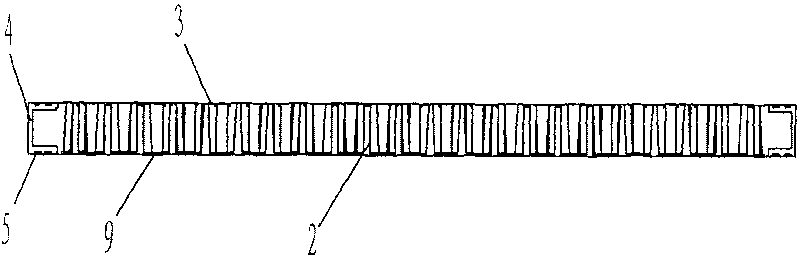

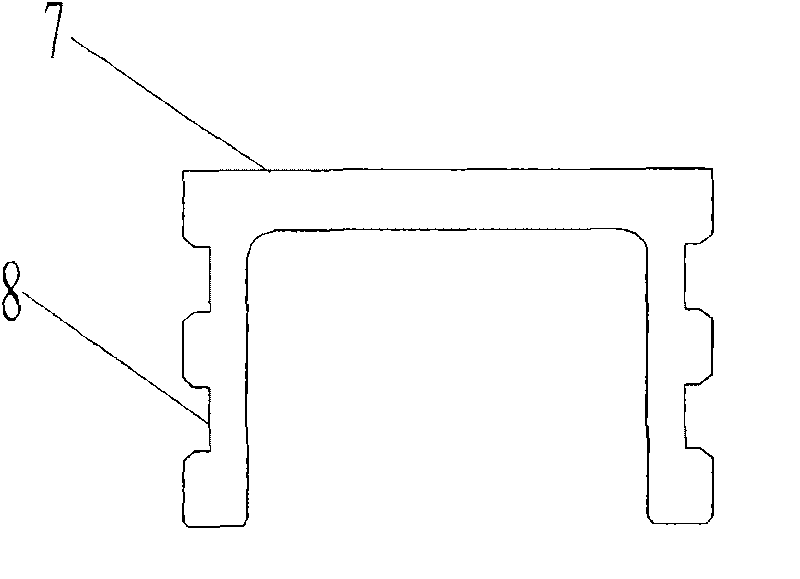

[0009] The existing condenser core is composed of condenser pipe 1 and cooling fins 2, see figure 1 . In the present invention, a U-shaped groove 7 is formed on both ends of the condenser core 6, and a groove 8 is formed on it. The plate assembly 9 is composed of a plate 3, a plate U-shaped groove 4, cooling fins 2 and adhesive glue 5, and a plate assembly 9. The U-shaped groove 4 has a groove 8 on it, and is placed at both ends of the plate assembly. There are U-shaped grooves at both ends of the plate, and the cooling fin and the U-shaped groove of the plate are placed between the plate 3 and the plate 3. Adhesive glue 5 is connected to form plate assembly 9 , condenser core 6 is composed of multiple plate assemblies 9 and multiple U-shaped grooves bonded by adhesive glue, and the middle of plate assembly 8 and plate assembly 8 forms cavity channel 9 . The bonding area is increased by adopting the U-shaped groove and the groove, the adhesive glue 5 is not easy to fall off, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com