Upper water and wire outlet structure of built-in submerged motor pump

A submersible electric pump, built-in technology, applied in the field of general mechanical product manufacturing, can solve problems such as unusable, large radial size of the unit, inconvenient installation and use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

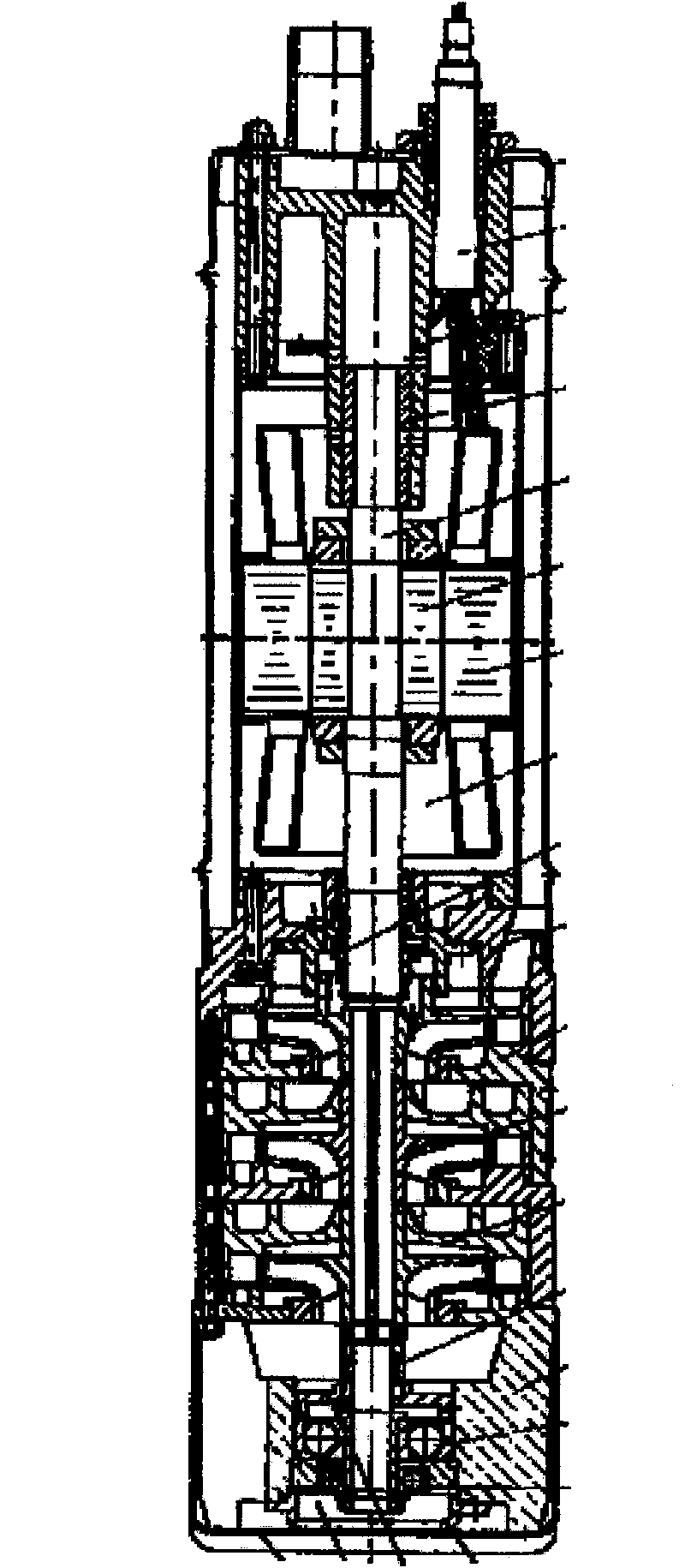

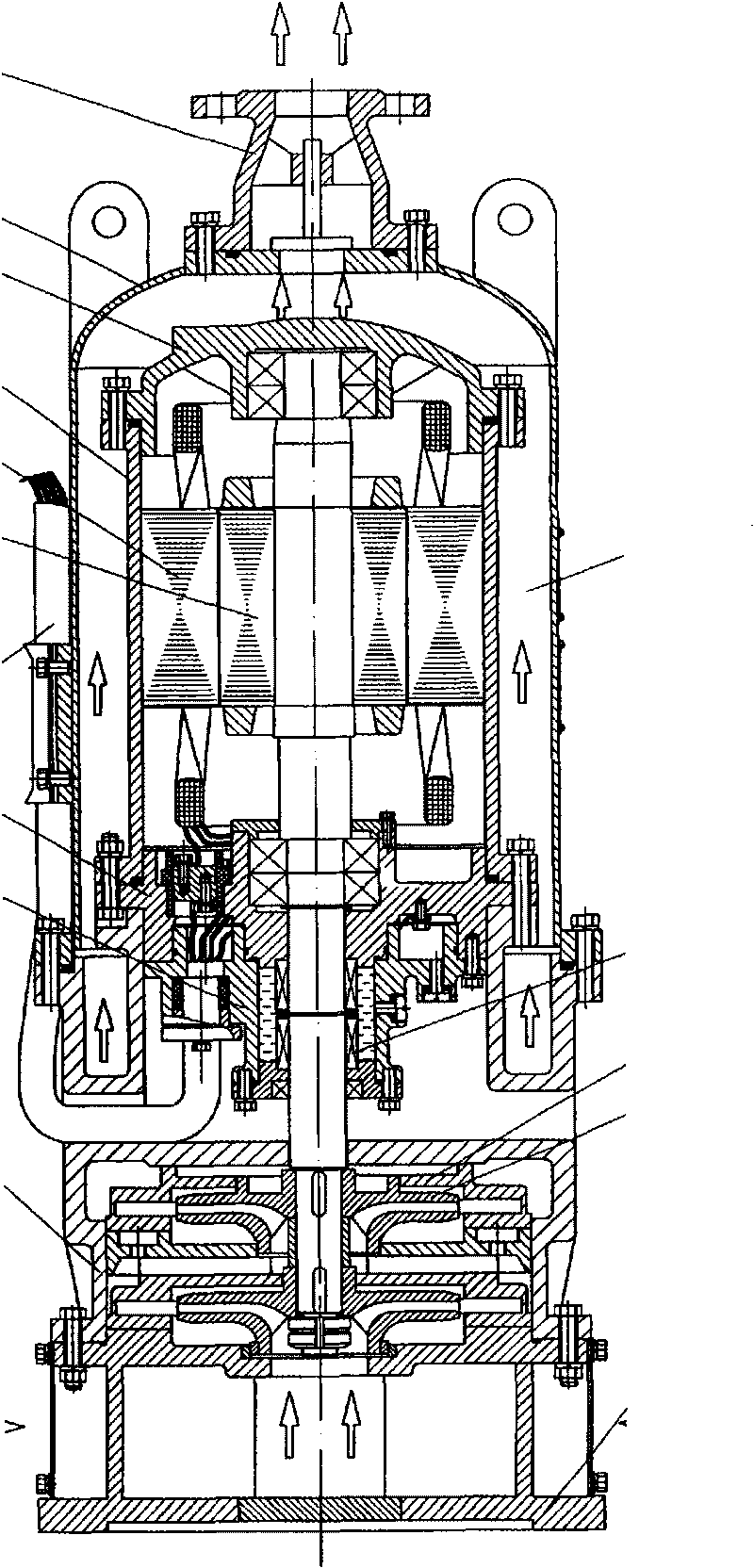

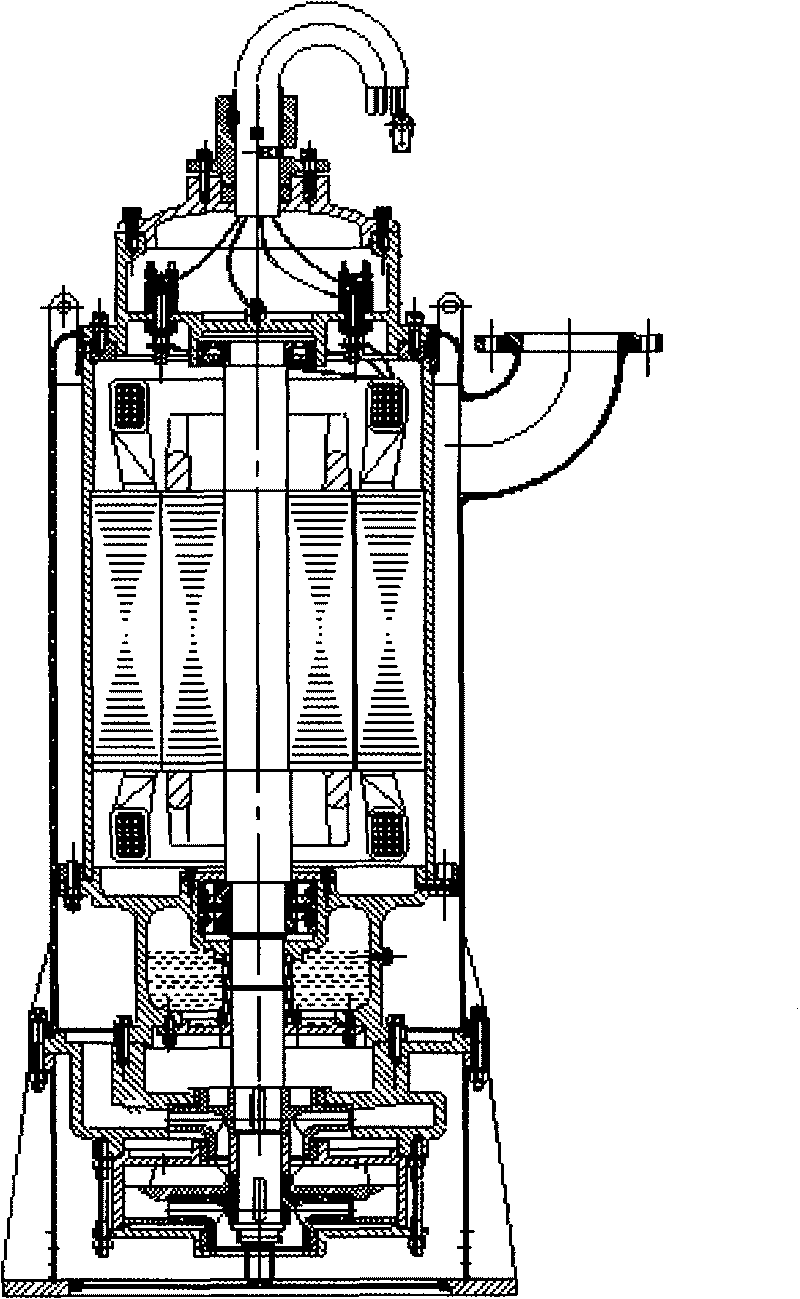

[0015] Figure 4 The shown embodiment is a mining explosion-proof built-in submersible pump, Figure 5 is a partial view of the innovative part of this embodiment. exist Figure 4 and Figure 5 Among them, the junction box 12 is located on the upper part of the unit, and there are 6 terminal posts 13 inside, which are used to change the wiring mode of the motor coil 7. The lower part of the junction box and the motor housing 16 have a matching notch 6, and the notch 6 is connected to the shaft center of the unit. The line 8 is concentric, the upper part of the junction box and the junction box cover 2 have a matching stop 5, the stop 5 is concentric with the axis line of the unit, the cable 1 of the unit is drawn out from the upper part of the junction box cover, and the outlet pipe 10 of the unit is connected to the upper part of the unit. The cover 3 is an integral part, the lower part of the water outlet pipe communicates with the cooling cavity 14 between the unit jacke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com