Upper-detachable breakdown structure of three-eccentric-butterfly-valve

A triple-eccentric butterfly valve, eccentricity technology, applied in the direction of the valve shell structure, lift valve, valve details, etc., can solve problems such as difficult maintenance, long maintenance time, and restrictions on the popularization and use of butterfly valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

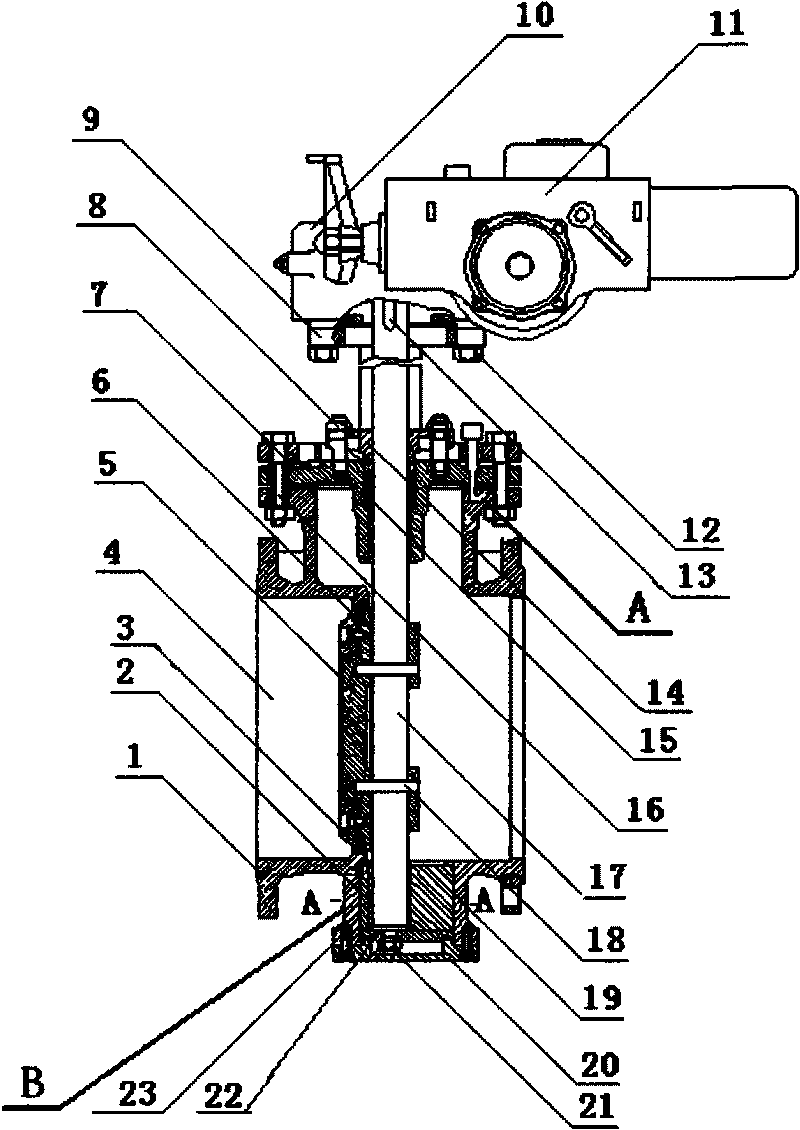

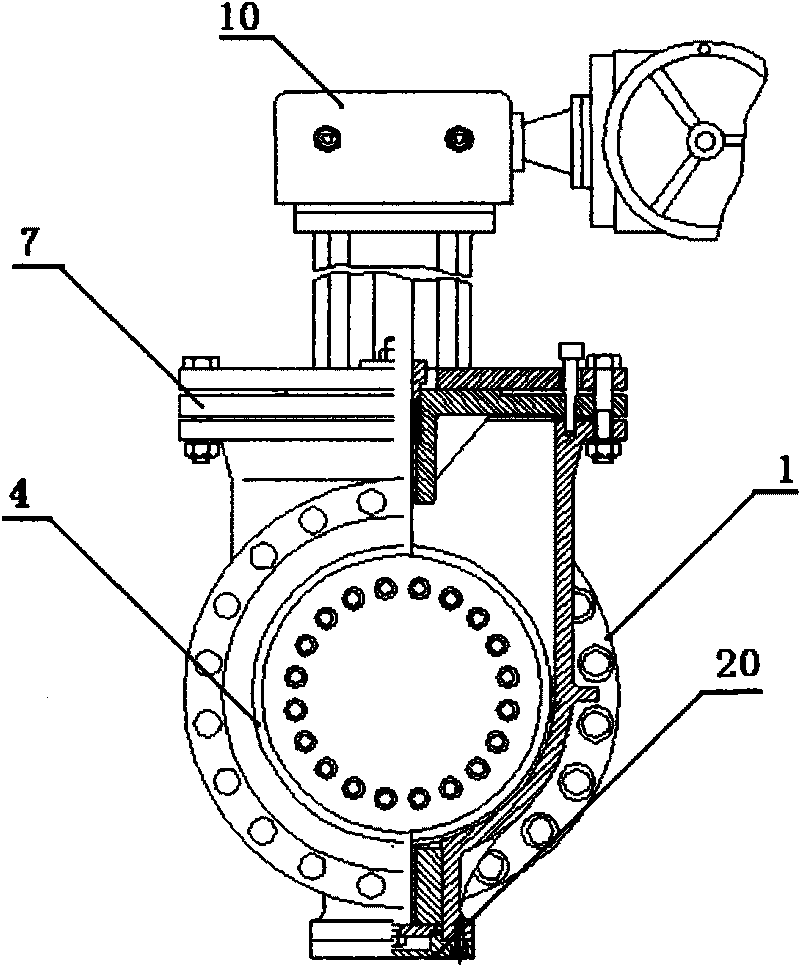

[0012] As shown in the figure, this kind of three-eccentric butterfly valve can be disassembled and disassembled, including four-way tubular valve body 1, valve cover 7, valve stem 17, butterfly plate 5, sealing ring 6, and valve stem 17 connects with pin 18 The butterfly plate 5 arranged in the middle of the rod body constitutes the intercepting surface of the valve cavity, and its characteristic is that the valve body at the lower end of the valve rod 17 is a lower branch valve body B with a certain eccentricity with the upper branch valve body A,

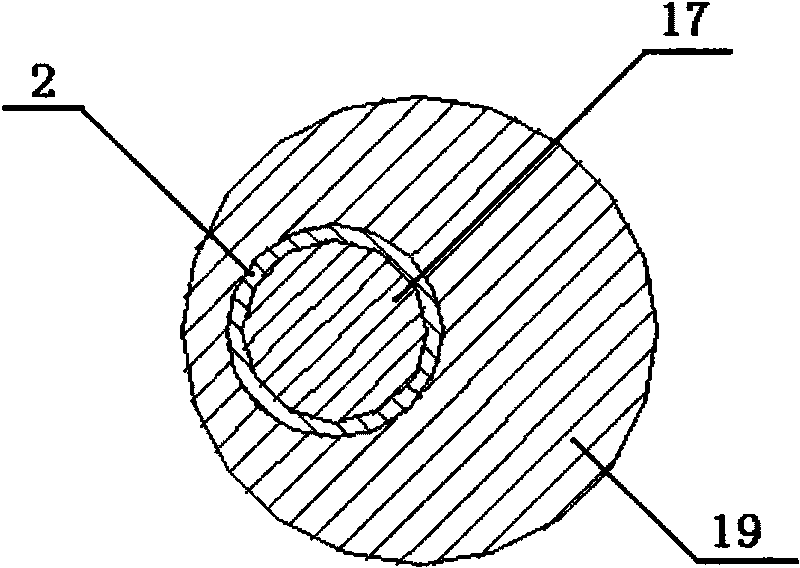

[0013] The end of the valve stem 17 placed in the inner cavity of the branch valve body B is provided with a shaft sleeve 2 coaxial with the valve stem, and an eccentric shaft sleeve 19 is added outside the sleeve at the same time, so that the entire assembly can be disassembled. The lower positioning structure of the valve stem drives the butterfly plate to translate to one side of the valve cavity.

[0014] The lower end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com