Method for online treatment of water leakage of cooling wall water supply branch pipe of blast furnace hearth

A technology for water supply branch pipes and blast furnaces, which is applied in the direction of cooling devices, etc., can solve the problems of reducing the temperature of refractory materials, affecting the longevity of blast furnaces, and uneconomical problems, achieving the effects of reducing losses, improving safety and reliability, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

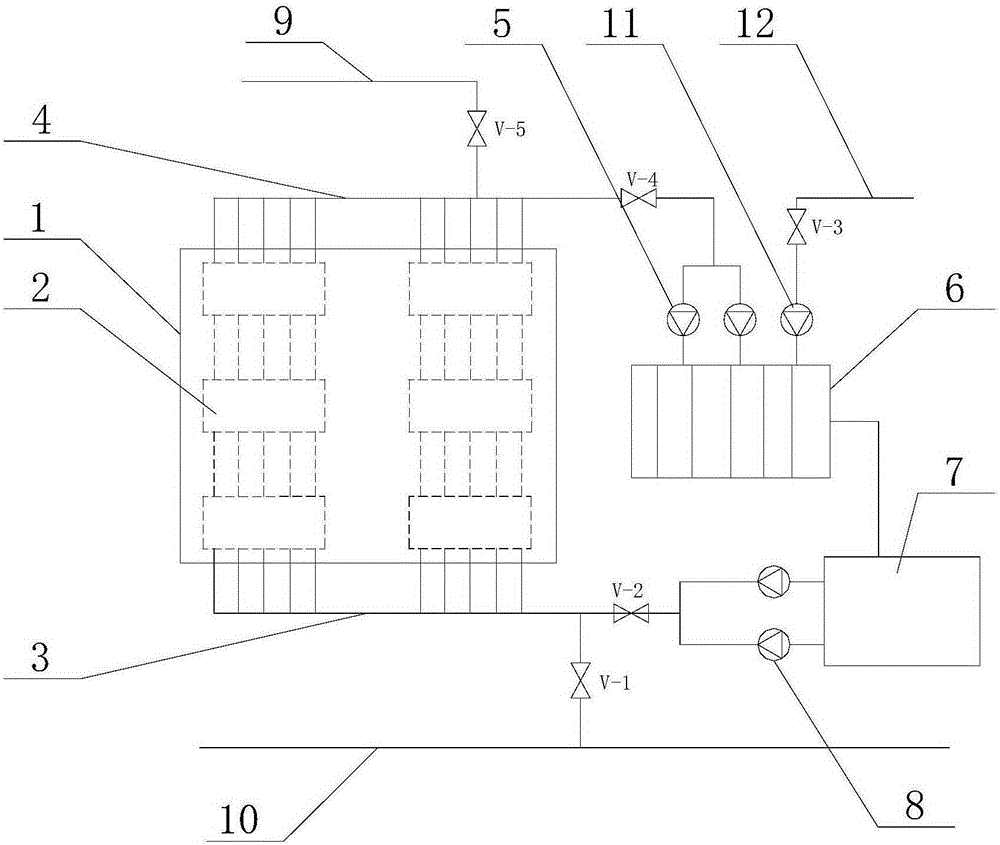

[0019] This embodiment provides a method for on-line treatment of water leakage from a water supply branch pipe of a blast furnace hearth cooling stave. The cooling stave of a blast furnace hearth 1 treated by this method is provided with a plurality of cooling cavities 2. The cooling cavities 2 in the height direction pass through vertical pipes. The straight branch pipes are connected, the lower end of the blast furnace hearth 1 is provided with a hearth water supply pipe 3, the upper end of the blast furnace hearth 1 is provided with a hearth water outlet pipe 4, and the hearth water outlet pipe 4 is connected with the cooling tower 6 through the first water pump 5, and the cooling tower 6 is connected to the reservoir 7, the reservoir 7 is communicated with the hearth water supply pipe 3 through the second water pump 8, a valve V-4 is provided between the first water pump 5 and the hearth water outlet pipe 4, and the second water pump 8 is connected to the hearth water suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com