Valve for fluid

A fluid and large fluid technology, applied in the field of metal rings, can solve problems such as damage, metal sheets 24 combined into one structure, and corrosion, and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

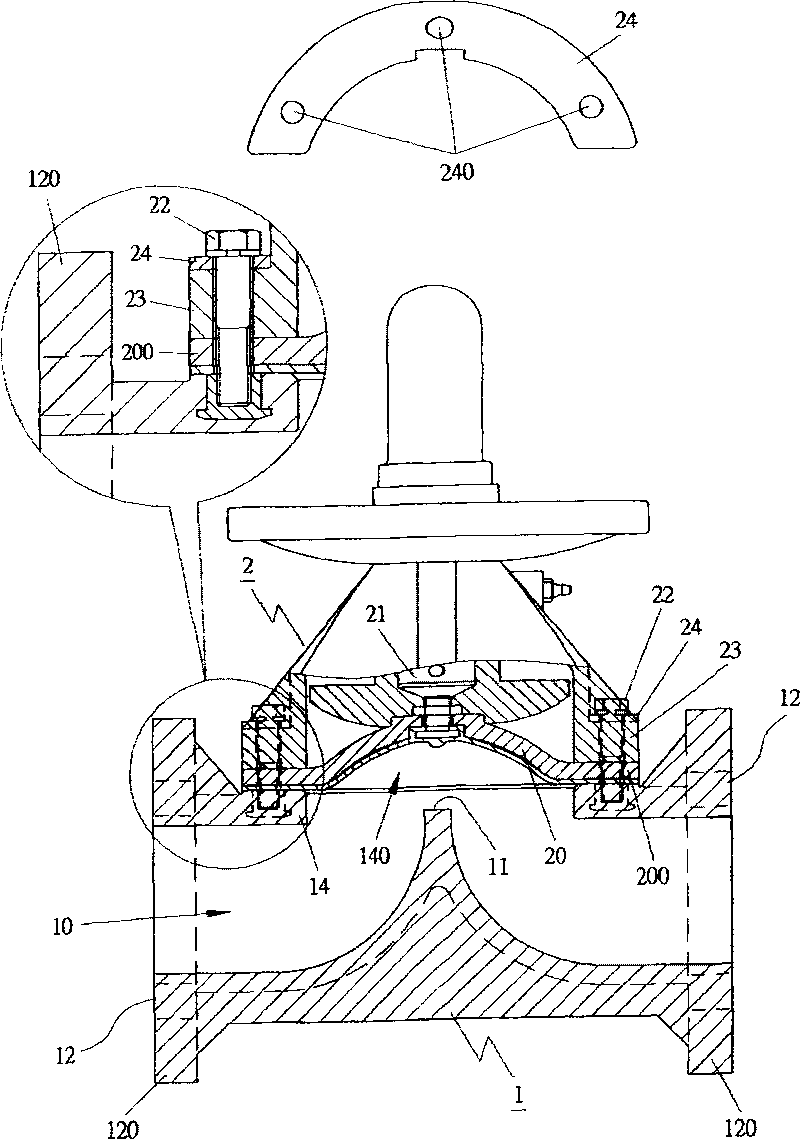

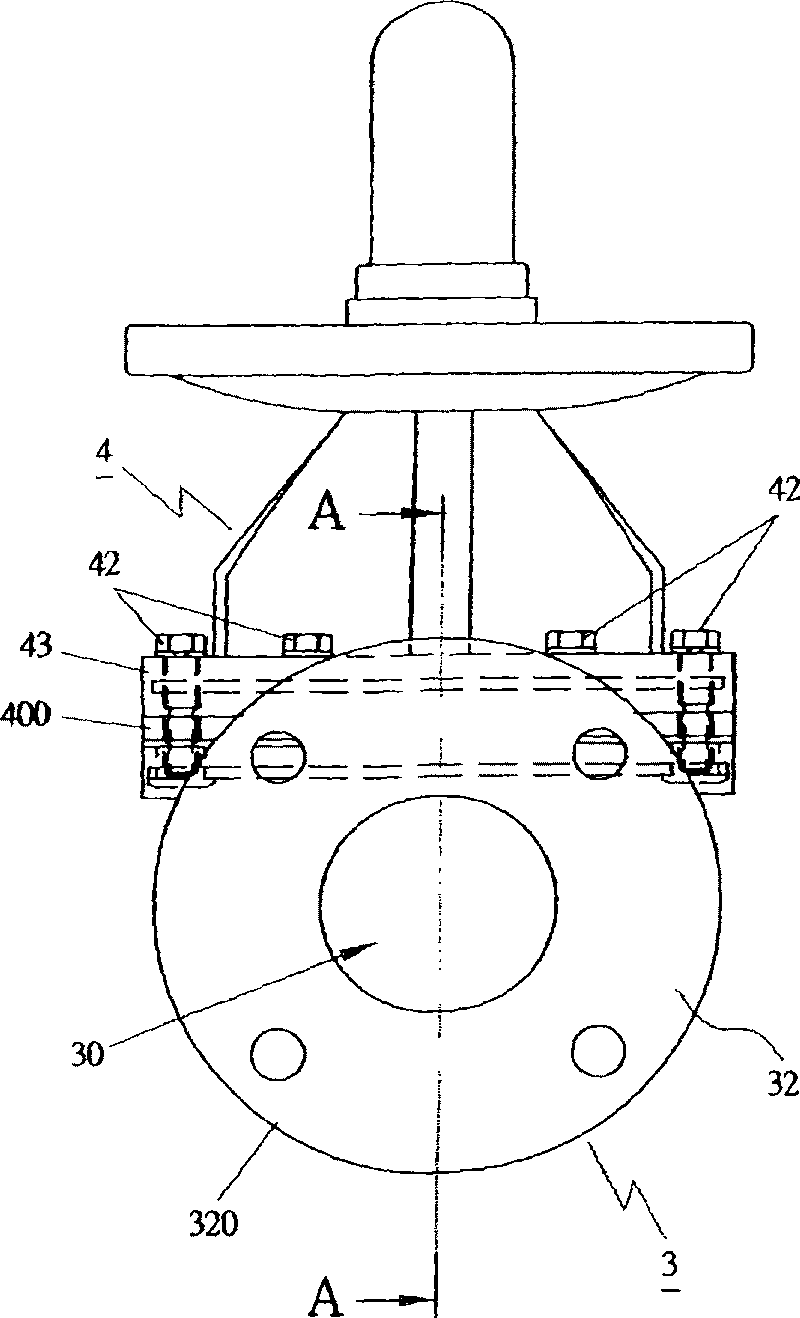

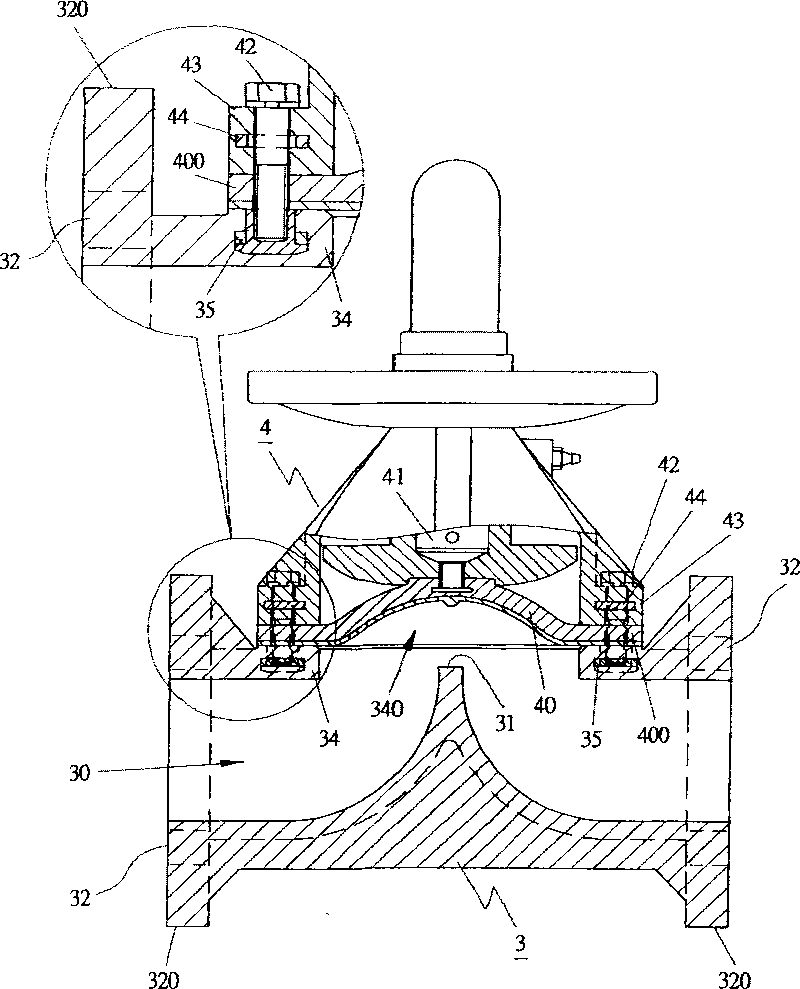

[0030] The fluid valve or valve of the present invention refers to a fluid valve or valve that can be applied to various structures, such as a diaphragm valve; or a diaphragm valve of any type; or a swing diaphragm valve; or a check valve; or a butterfly valve, for To enable your examiner to fully understand the present invention, it is explained as follows according to the attached drawings:

[0031] Such as figure 2 and 3 , Image 6 The embodiments shown are all diaphragm valves; as Figure 7 and 8 The embodiment is by any type (TRUE UNION) diaphragm valve; Figure 9 The embodiment shown is a swing diaphragm valve; as Figure 10 The embodiment shown is a check valve; as Figure 11 and 12 The illustrated embodiment is a butterfly valve, and each of the above embodiments includes:

[0032] The body 3 is provided with an integrally formed fluid flow hole 30 on the body 3, and the flow hole 30 is connected with the image 3 ;or Image 6 ;or Figure 7 ;or Figure 9 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com