Method for extracting time-frequency amplitude characteristic and time-frequency phase characteristic of ultrasonic signals on dissimilar material diffusion welding interface

A technology of ultrasonic signals and heterogeneous materials, applied in the direction of processing detection response signals, etc., can solve problems such as inability to accurately reflect diffusion welding defect information, and achieve the effects of reducing the amount of calculation, avoiding phase distortion, and high similarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

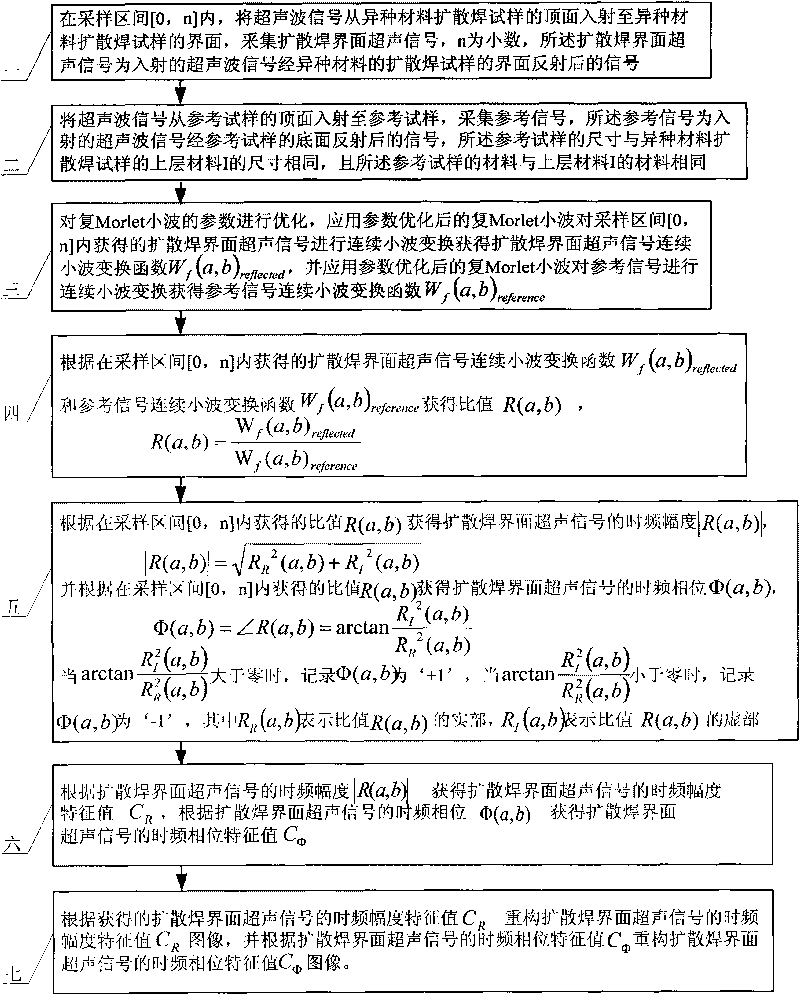

specific Embodiment approach 1

[0014] Specific implementation mode 1: According to the instructions attached figure 1 To describe this embodiment in detail, the method for extracting time-frequency amplitude characteristics and time-frequency phase characteristics of ultrasonic signals at the interface of dissimilar material diffusion welding described in this embodiment, said dissimilar material diffusion welding interface is the interface of dissimilar material diffusion welding sample, and The dissimilar material diffusion welding sample is welded by the upper material I and the lower material II, and the steps of the extraction method are:

[0015] Step 1: In the sampling interval [0, n], the ultrasonic signal is incident from the top surface of the dissimilar material diffusion welding specimen to the interface of the dissimilar material diffusion welding specimen, and the ultrasonic signal of the diffusion bonding interface is collected, and n is a decimal. The ultrasonic signal of the diffusion welding ...

specific Embodiment approach 2

[0024] Specific embodiment 2: This embodiment is a further description of the method for extracting time-frequency amplitude characteristics and time-frequency phase characteristics of ultrasonic signals at the interface of dissimilar material diffusion welding described in specific embodiment 1, as described in step three in specific embodiment 1. Continuous wavelet transform function of ultrasonic signal of diffusion welding interface W f (a, b) reflected And reference signal continuous wavelet transform function W f (a, b) reference By formula Obtained, where f(t) correspondingly represents the ultrasonic signal or reference signal of the diffusion welding interface, ψ(t) represents the wavelet mother function, and the wavelet mother function is the complex Morlet wavelet, Represents the continuous wavelet function dependent on the parameters a and b generated by the wavelet mother function ψ(t), called wavelet for short, a represents the scale parameter, which reflects the ...

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment is a further description of the method for extracting time-frequency amplitude characteristics and time-frequency phase characteristics of ultrasonic signals at the interface of dissimilar material diffusion welding described in the first embodiment. In step six of the first embodiment, according to the diffusion The time-frequency amplitude of the ultrasonic signal of the welding interface|R(a,b)|The time-frequency amplitude characteristic value C of the ultrasonic signal of the diffusion welding interface is obtained R The method is based on each time parameter b in the sampling interval [0, n] j The time-frequency amplitude of the ultrasonic signal of the diffusion bonding interface|R(a, b j )|Get the time-frequency amplitude characteristic value C of the ultrasonic signal of the diffusion welding interface R , The specific process is: the each time parameter b j The time-frequency amplitude of the ultrasonic signal of the diffusion bonding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com