Lens driving device and urging force adjusting method for elastic member

A technology of lens driving device and elastic parts, which can be used in installation, optical components, instruments, etc., and can solve problems such as increasing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

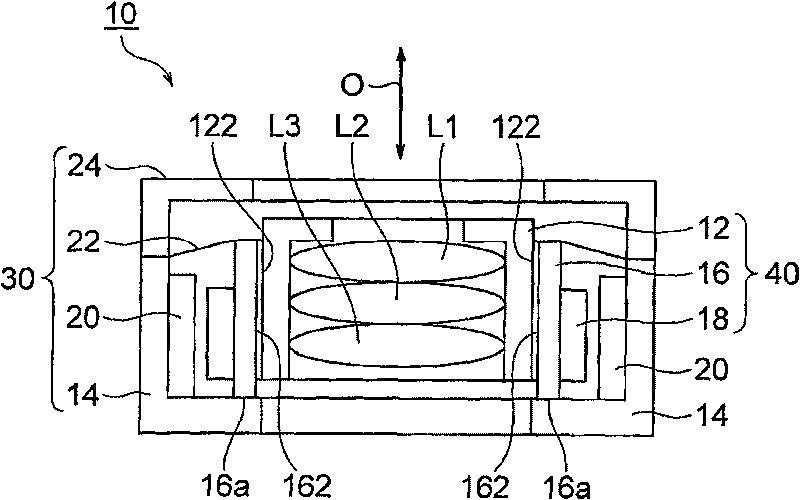

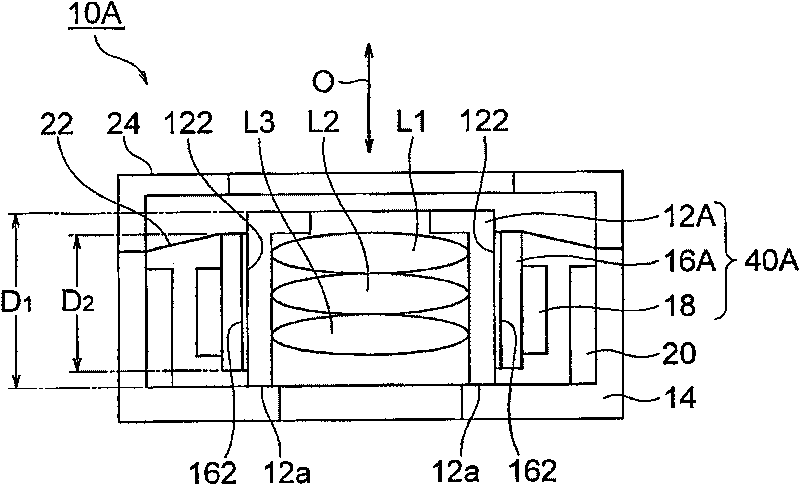

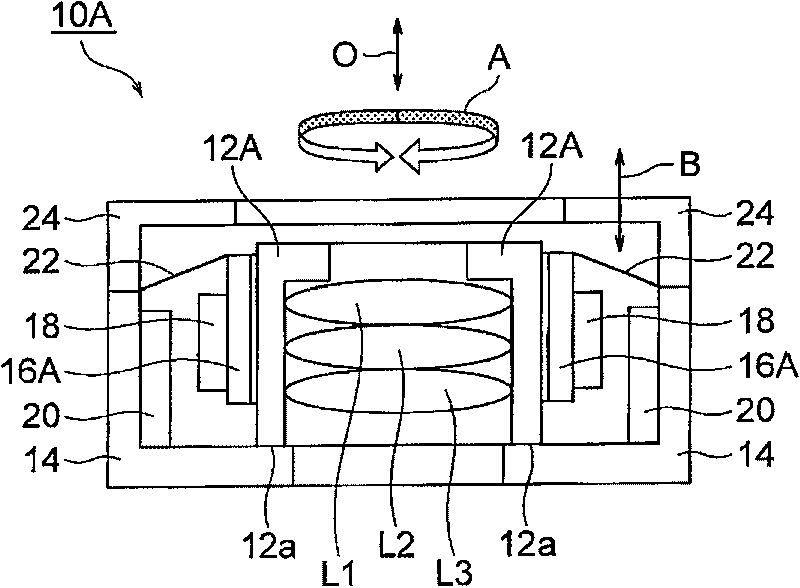

[0021] refer to figure 1 , in order to facilitate the understanding of the present invention, the relevant lens driving device 10 will be described. figure 1 It is a schematic sectional view showing main parts inside the lens driving device 10 . exist figure 1 In the example shown, the up-down direction is the direction of the optical axis O of the lens.

[0022] However, in an actual use situation, the direction of the optical axis O, that is, the up-down direction is the front-rear direction. In other words, the upward direction is the front direction, and the downward direction is the rear direction.

[0023] The illustrated lens driving device 10 is equipped with a mobile phone with an auto-focusable camera. The lens driving device 10 is used to move the lens drum 12 including the plurality of lenses L1, L2, and L3 in the optical axis O direction. The lens dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com