Outer rotor motor

An external rotor motor and external rotor technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of impeller yaw, different bearing specifications, noise, etc., to achieve not easy to beat, ensure concentricity, and low noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

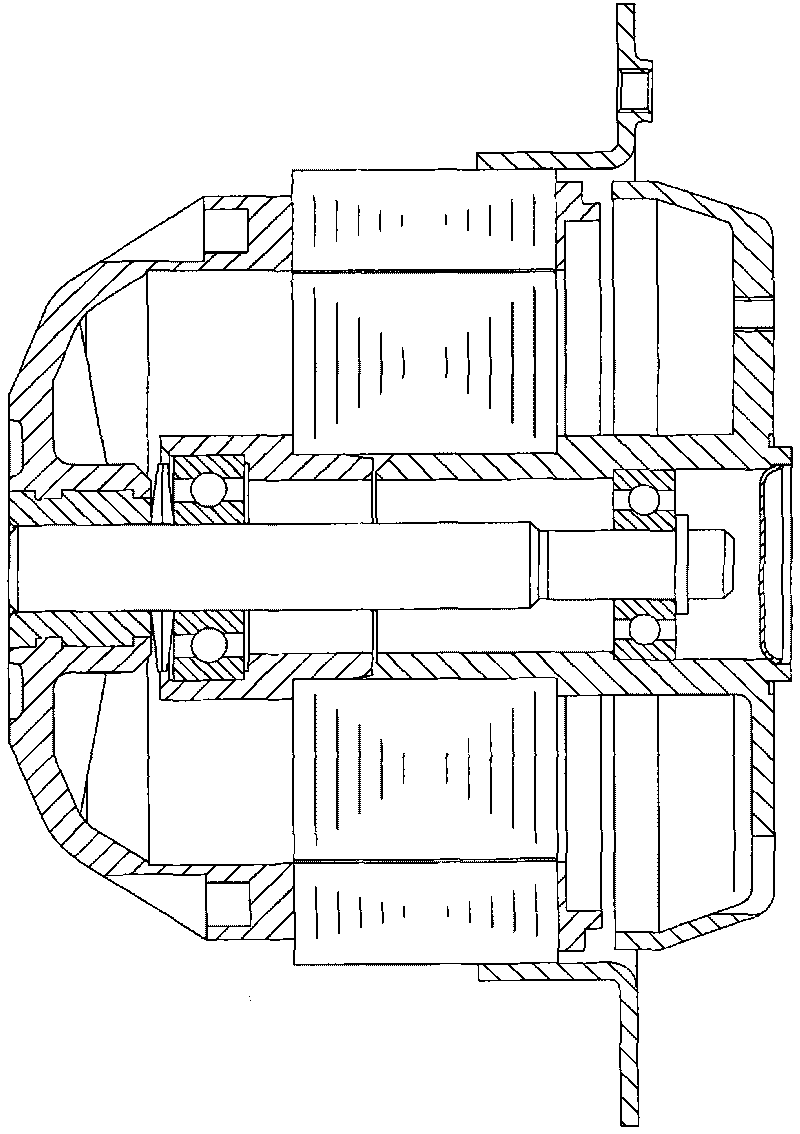

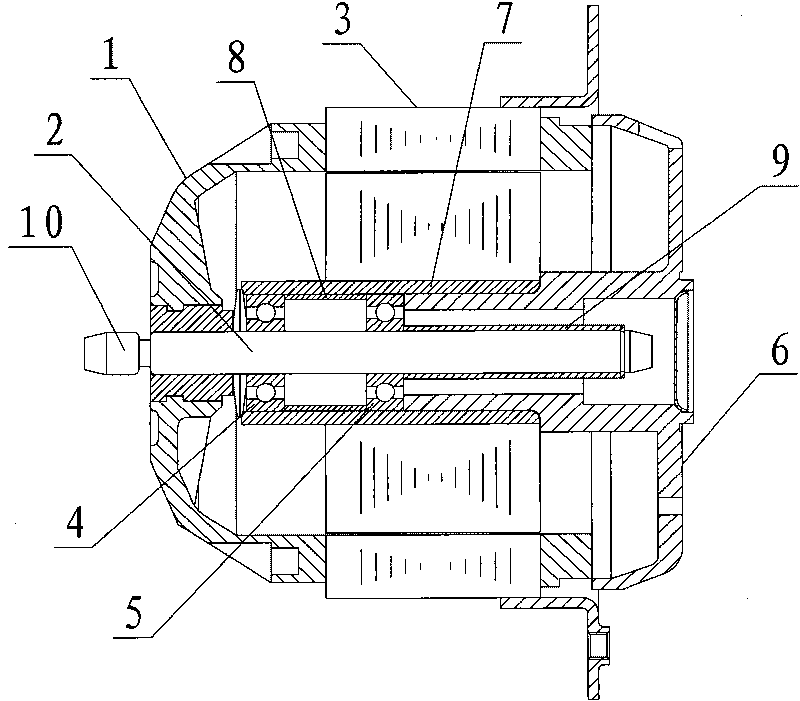

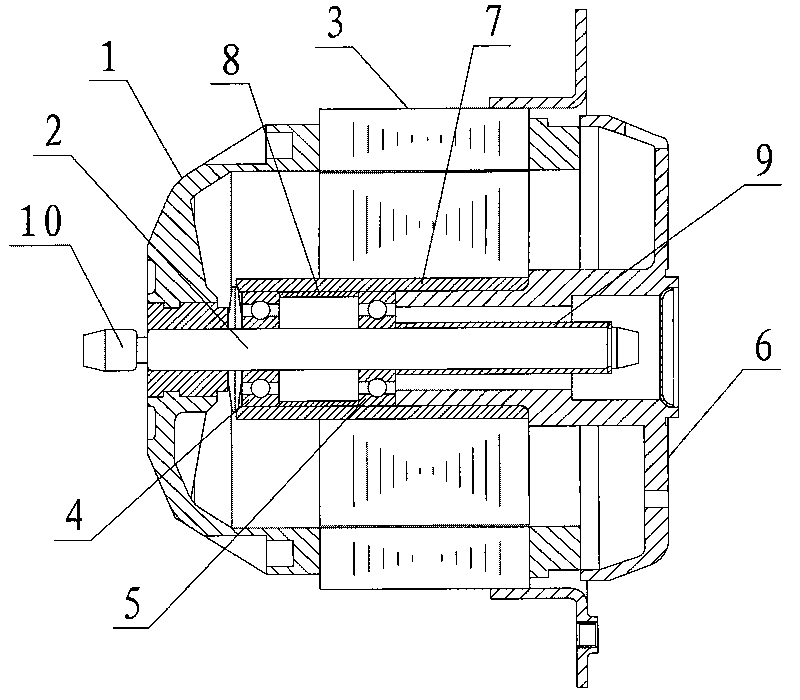

[0019] Such as figure 2 The outer rotor motor shown has an outer rotor 1, a rotating shaft 2, a stator core 3, a first bearing 4, a second bearing 5 and an end cover 6, and the inner hole of the stator core 3 is press-fitted with a first sleeve 7, The first bearing 4 and the second bearing 5 are bearings of the same specification, and both the first bearing 4 and the second bearing 5 are installed in the first casing 7 .

[0020] The first sleeve 7 covers the inner hole of the stator core 3 and axially exceeds the inner hole of the stator core 3 at one end close to the outer rotor 2 .

[0021] The first bearing 4 is installed in the first casing 7 close to one end of the outer rotor 2 and is connected with the outer rotor 2 through a compression spring.

[0022] The second bearing 5 is installed in the first sleeve 7 near one end of the end cover 6 , and the second bearing 5 is separated from the first bearing 4 by the second sleeve 8 .

[0023] The end cover 6 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com